NASCAR cars aren’t just vehicles – they’re precision-engineered racing machines that push the boundaries of automotive technology and human endurance. When we watch these incredible machines thunder around the track at speeds exceeding 200 mph, we’re witnessing decades of innovation and craftsmanship designed for one purpose: winning.

Behind every NASCAR car lies a intriguing area of aerodynamics, safety technology, and meticulous engineering that most fans never see. From their custom-built engines producing over 750 horsepower to their specialized tires that can withstand extreme temperatures, these race cars represent the pinnacle of motorsport engineering.

Whether you’re a longtime racing enthusiast or someone who’s curious about what makes these cars so special, understanding NASCAR vehicles opens up a whole new appreciation for America’s most popular motorsport. Let’s jump into the incredible technology and design that makes these racing machines truly extraordinary.

The Evolution of NASCAR Cars Through the Decades

The sophisticated engineering we’ve explored represents decades of innovation in NASCAR vehicle development. We’ll trace how these racing machines transformed from everyday automobiles into the high-tech marvels dominating today’s tracks.

From Stock Cars to Purpose-Built Machines

Stock car racing began with drivers literally racing cars straight from factory showrooms in the late 1940s. We witnessed the sport’s humble origins when competitors would drive their family sedans like Ford Galaxies and Plymouth Road Runners to weekend races across the Southeast. These vehicles retained their original engines, suspensions, and body panels with minimal modifications beyond safety equipment.

Manufacturers started recognizing NASCAR’s marketing potential during the 1960s, leading to the first purpose-built racing components. We saw automakers develop special racing packages including heavy-duty suspensions, larger fuel tanks, and performance-oriented engines specifically for competition use. Factory teams began emerging as Ford, Chrysler, and General Motors invested heavily in winning races to boost showroom sales.

The transition accelerated dramatically during the 1980s when NASCAR introduced the Car of Tomorrow concept development. We observed teams moving away from production-based chassis toward completely custom-fabricated frames designed exclusively for racing. Modern NASCAR Cup Series cars share virtually nothing with their street-going counterparts beyond basic silhouettes and manufacturer badges.

Key Technological Milestones in NASCAR History

Several breakthrough innovations fundamentally changed how NASCAR cars perform on track throughout the sport’s evolution.

| Year | Technology Introduction | Impact on Performance |

|---|---|---|

| 1967 | Aerodynamic body modifications | 15-20 mph speed increase |

| 1988 | Restrictor plates at superspeedways | Reduced speeds from 210+ to 190 mph |

| 2007 | Car of Tomorrow safety cage | 300% improvement in impact protection |

| 2022 | Next Gen car introduction | Standardized components across teams |

Safety innovations became paramount following tragic accidents that claimed drivers’ lives during the sport’s early decades. We witnessed the introduction of roll cages in the 1960s, followed by fire suppression systems, energy-absorbing barriers, and the life-saving HANS device that prevents basilar skull fractures during frontal impacts.

Electronic fuel injection replaced carburetors in 2012, marking NASCAR’s entry into modern engine management technology. We’ve seen teams gain precise control over fuel delivery, ignition timing, and engine performance through sophisticated computer systems that monitor hundreds of parameters in real time.

Tire technology evolved from basic street radials to specialized racing compounds developed exclusively for NASCAR competition. We now see teams choosing between different tire compounds based on track conditions, weather, and race strategy, adding another layer of complexity to vehicle setup and performance optimization.

Understanding NASCAR Car Specifications and Regulations

NASCAR enforces strict specifications and regulations to ensure fair competition and driver safety across all racing events. These comprehensive rules govern every aspect of car construction from engine performance to safety systems.

Engine Requirements and Restrictions

Engine specifications in NASCAR create a level playing field while maintaining the sport’s competitive edge. We see standardized 5.86-liter V8 engines that must produce exactly 670 horsepower at restrictor plate tracks and 750 horsepower at other venues. NASCAR mandates the use of electronic fuel injection systems manufactured by McLaren, replacing the traditional carburetors that dominated the sport for decades.

Displacement limits remain fixed at 358 cubic inches, while compression ratios cannot exceed 12:1 across all manufacturer engines. Teams must use NASCAR-approved engine blocks from Chevrolet, Ford, or Toyota, with each manufacturer’s design meeting identical performance parameters. Engine RPM gets capped at 9,000 revolutions per minute through electronic limiters that prevent teams from gaining unfair advantages through excessive engine speeds.

Fuel delivery systems require NASCAR-approved components including exact fuel pumps, filters, and injection mapping software. We observe strict regulations on camshaft specifications, valve timing, and intake manifold designs that ensure competitive parity between different manufacturers.

Safety Equipment Mandated by NASCAR

Safety equipment requirements in NASCAR represent decades of technological advancement and tragic lessons learned from racing incidents. We require drivers to wear five-point safety harnesses manufactured by certified suppliers like Simpson or Sparco, with mandatory replacement every two years regardless of condition.

HANS (Head and Neck Support) devices became mandatory in 2003 following Dale Earnhardt’s fatal crash, reducing basilar skull fractures by over 90% according to NASCAR safety data. Roll cages must meet precise specifications using DOM (Drawn Over Mandrel) steel tubing with exact wall thickness measurements and strategic placement of support bars.

Fire suppression systems include onboard extinguishers that activate automatically when crash sensors detect impacts exceeding predetermined G-force thresholds. Driver suits require Nomex construction with minimum flame resistance ratings, while helmets must pass rigorous Snell Foundation testing standards updated every five years.

Window nets prevent driver limbs from extending outside the car during crashes, while roof flaps automatically deploy when cars reach exact angles to prevent dangerous airborne situations. We see additional safety innovations like energy-absorbing foam in door panels and breakaway throttle linkages that prevent unintended acceleration during accidents.

Aerodynamic Design Standards

Aerodynamic regulations in NASCAR balance competitive racing with safety considerations through precisely defined body templates. We measure every surface using laser scanning technology to ensure compliance with NASCAR’s digital templates that specify exact dimensions for hoods, spoilers, and body panels.

Rear spoilers must measure exactly 8 inches in height with predetermined angles that create optimal downforce levels across different track configurations. Front splitters extend exact distances from the nose with regulated flexibility that prevents teams from gaining aerodynamic advantages through creative interpretations.

Side skirt heights get measured at multiple points to prevent teams from creating ground effects that could make cars unstable at high speeds. NASCAR allows minimal aerodynamic adjustments through approved tape placement on grille openings, but these modifications must fall within strict parameters monitored by technical inspectors.

Manufacturer-exact body shapes maintain brand identity while meeting identical aerodynamic coefficients measured in NASCAR’s wind tunnel facility. We observe continuous updates to these templates as NASCAR refines the balance between competitive racing and safety requirements based on real-industry track performance data.

The Most Iconic NASCAR Cars in Racing History

Throughout NASCAR’s storied evolution, certain racing machines have transcended mere competition to become legendary symbols of the sport. We’ve witnessed extraordinary vehicles that captured our imagination and defined entire eras of stock car racing.

Richard Petty’s Plymouth Superbird

The Plymouth Superbird dominated NASCAR tracks in 1970 with its distinctive aerodynamic design and towering rear spoiler. Richard Petty piloted this winged warrior to 18 victories during the 1970 season, including eight wins in his iconic STP-sponsored number 43. Chrysler engineered the Superbird specifically to compete with Ford’s aerodynamic advantages, featuring a distinctive nose cone and massive rear wing that stood nearly three feet tall.

Performance specifications made the Superbird nearly unstoppable on superspeedways. The car’s 440 cubic inch V8 engine produced over 375 horsepower, while its revolutionary aerodynamic package reduced drag coefficients significantly compared to standard Plymouth Road Runners. NASCAR officials eventually banned the Superbird’s extreme aerodynamic modifications after just two seasons, cementing its status as one of the most innovative yet controversial designs in racing history.

Racing enthusiasts still recognize the Superbird’s distinctive profile decades later. We often see replicas and tributes to Petty’s winged machine at car shows and NASCAR events, demonstrating its lasting impact on automotive culture. The car’s success helped establish Petty as “The King” and remains one of the most photographed vehicles in motorsports history.

Dale Earnhardt’s Black Monte Carlo

Dale Earnhardt’s intimidating black Chevrolet Monte Carlo became synonymous with aggressive driving and championship success throughout the 1980s and 1990s. The Goodwrench-sponsored number 3 car earned Earnhardt seven Cup Series championships, with six of those titles coming behind the wheel of various Monte Carlo iterations. Chevrolet’s aerodynamic improvements to the Monte Carlo platform provided Earnhardt with the competitive edge needed to dominate restrictor plate racing at Daytona and Talladega.

Engineering excellence defined the Monte Carlo’s performance capabilities during Earnhardt’s championship runs. The car featured refined suspension geometry that allowed for better handling in traffic, while its aerodynamic nose design helped maintain stability at high speeds. Earnhardt’s Monte Carlo typically produced between 650-700 horsepower from its small block V8 engine, depending on track configuration and NASCAR regulations.

Cultural significance elevated the black Monte Carlo beyond mere racing success. We remember how Earnhardt’s aggressive driving style, combined with the car’s menacing appearance, earned him the nickname “The Intimidator.” The number 3 Monte Carlo became a marketing phenomenon, generating millions in merchandise sales and establishing one of the most recognizable paint schemes in all of motorsports.

Jeff Gordon’s Rainbow Warriors

Jeff Gordon’s multicolored DuPont Chevrolets revolutionized NASCAR marketing and attracted new demographics to stock car racing during the 1990s. The vibrant rainbow paint scheme on Gordon’s number 24 Monte Carlo and later Impala models stood out dramatically against traditional racing colors, helping NASCAR expand its appeal beyond regional boundaries. Gordon captured four Cup Series championships driving these colorful machines between 1995 and 2001.

Technical innovations distinguished Gordon’s Rainbow Warriors from competing vehicles. Hendrick Motorsports engineers developed advanced chassis setups that maximized the aerodynamic potential of Chevrolet’s body styles, while Gordon’s cars consistently featured cutting edge suspension components and engine management systems. The team’s attention to detail resulted in 93 career victories, with many coming in the distinctive rainbow livery.

Marketing impact transformed NASCAR’s commercial industry through Gordon’s Rainbow Warriors. We witnessed how DuPont’s bold color choices attracted corporate sponsors who previously avoided stock car racing, leading to increased television coverage and mainstream media attention. The Rainbow Warriors merchandise became some of the best selling NASCAR products ever, proving that innovative paint schemes could drive important revenue growth for teams and manufacturers alike.

How NASCAR Cars Differ from Street Vehicles

NASCAR cars represent a complete departure from everyday street vehicles, with every component redesigned for maximum performance and safety on the racetrack. We’ll explore the fundamental differences that transform ordinary car designs into high-speed racing machines.

Chassis and Frame Construction

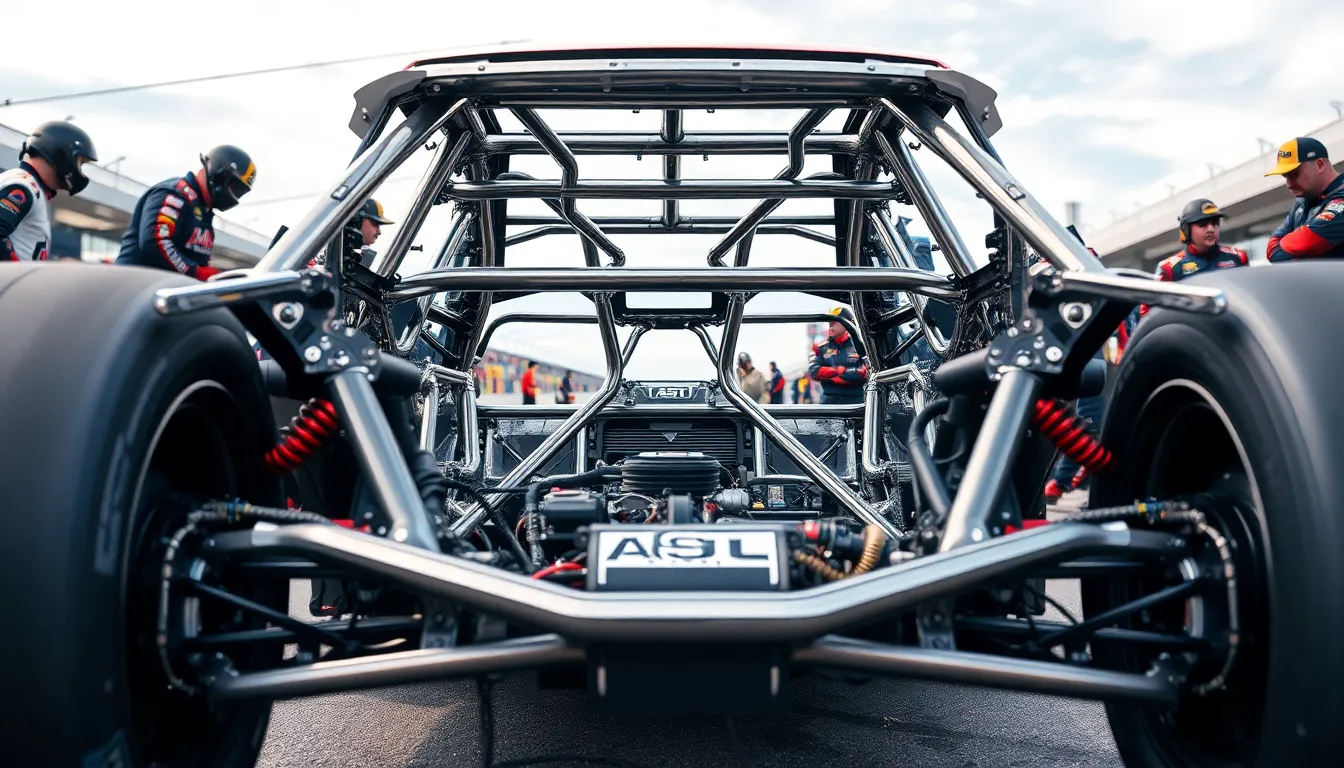

NASCAR cars use a tubular steel space frame that’s completely different from standard vehicle construction methods. Street cars rely on unibody construction that integrates the body panels with structural support, while racing vehicles feature separate chassis built from 1.75-inch diameter steel tubing that creates an incredibly strong cage around the driver.

Roll cage integration forms the foundation of NASCAR construction, with over 100 feet of steel tubing welded together to create a protective cocoon. Street vehicles don’t include roll cages since they’re designed for normal driving conditions rather than high-speed impacts at 200 mph.

Weight distribution differs dramatically between NASCAR and street cars, with racing machines designed to achieve perfect 50/50 front-to-rear balance. Manufacturers place the engine, transmission, and fuel cell in exact locations to optimize handling characteristics that would feel completely foreign in everyday driving situations.

Body panels on NASCAR cars are purely cosmetic fiberglass or carbon fiber shells that bolt onto the chassis frame. Regular automobiles integrate body panels as structural components that contribute to vehicle rigidity and safety, while racing cars separate these functions entirely.

Engine Performance Modifications

NASCAR engines produce nearly three times the horsepower of typical street car powerplants through extensive internal modifications and specialized components. We see naturally aspirated 5.86-liter V8 engines that generate 750 horsepower compared to street engines that typically produce 200-400 horsepower from similar displacement.

Internal engine components include forged pistons, connecting rods, and crankshafts designed to withstand extreme stress and temperatures. Street car engines use cast components that prioritize longevity and fuel efficiency over maximum power output, lasting 150,000+ miles versus NASCAR engines that require rebuilds every few races.

Fuel delivery systems employ electronic fuel injection calibrated for racing fuel rather than pump gasoline. Racing engines run on specially formulated fuel with higher octane ratings and different chemical compositions that would damage street car fuel systems and void manufacturer warranties.

Cooling systems feature oversized radiators, oil coolers, and transmission coolers that handle heat loads far exceeding street vehicle requirements. NASCAR cars generate enough heat to warm a small house, requiring specialized cooling answers that would be unnecessary and impractical for daily driving.

Interior Safety Features

NASCAR interiors focus entirely on driver protection rather than passenger comfort or convenience features found in street vehicles. Racing cockpits include five-point harness systems that secure drivers at the shoulders, waist, and between the legs, compared to standard three-point seatbelts in regular cars.

HANS devices (Head and Neck Support) mount to driver helmets and shoulders to prevent basilar skull fractures during frontal impacts. Street cars rely on airbags and crumple zones for occupant protection, while NASCAR cars use rigid structures that transfer crash energy around the driver compartment.

Fire suppression systems automatically deploy flame-retardant chemicals throughout the cockpit when sensors detect fire or extreme heat. Regular vehicles don’t include fire suppression since the risk of fire during normal operation is minimal compared to racing environments where fuel, heat, and friction create constant fire hazards.

Window nets replace standard door glass to prevent driver arms from extending outside the vehicle during rollovers or side impacts. Street cars use safety glass designed to protect occupants from weather and debris while maintaining visibility, whereas NASCAR window nets prioritize driver containment over environmental protection.

The Role of Manufacturers in NASCAR Car Development

Manufacturers play a crucial role in NASCAR car development, providing engineering expertise and technological innovations that push the sport’s boundaries. We see how these automotive giants compete not just on the track but in research facilities where they develop cutting-edge racing technologies.

Chevrolet’s Dominance in NASCAR

Chevrolet stands as NASCAR’s most successful manufacturer with over 40 Cup Series championships since the sport’s inception. The bow tie brand has claimed victory in legendary races with iconic models like the Monte Carlo, Impala, and current Camaro ZL1.

General Motors invests millions annually in NASCAR research and development through their racing division. Engineers at Chevrolet work closely with teams like Hendrick Motorsports and Richard Childress Racing to optimize aerodynamic packages and engine performance. The manufacturer’s commitment shows in their 13 manufacturer championships since 2003.

Chevrolet’s NASCAR engines produce approximately 750 horsepower on non-restrictor plate tracks through advanced fuel injection systems and precision engineering. Teams benefit from the brand’s extensive parts catalog and technical support network that spans across all NASCAR series. The manufacturer’s success attracts top-tier teams and drivers who recognize Chevrolet’s competitive advantages.

Ford’s Racing Heritage and Innovation

Ford brings decades of motorsports heritage to NASCAR with their “Win on Sunday, Sell on Monday” philosophy that dates back to the 1960s. The Blue Oval currently fields the Mustang GT in Cup Series competition, continuing a legacy that includes victories with the Taurus, Fusion, and Thunderbird models.

Ford Performance engineers collaborate with teams like Team Penske and Stewart-Haas Racing to develop advanced racing technologies. The manufacturer pioneered several NASCAR innovations including electronic fuel injection systems and advanced aerodynamic designs that improve on-track performance. Their technical centers in Dearborn and Charlotte provide teams with wind tunnel testing and computational fluid dynamics analysis.

Racing success translates directly to Ford’s street car development as NASCAR technologies often find their way into production vehicles. Ford’s NASCAR program employs over 200 engineers and technicians who work exclusively on racing applications. The manufacturer’s recent investments in hybrid technology and sustainable fuels position them for NASCAR’s evolving future.

Toyota’s Entry into NASCAR Competition

Toyota entered NASCAR competition in 2007 with their Camry model, bringing fresh perspectives and innovative approaches to stock car racing. The Japanese manufacturer faced initial resistance from traditional NASCAR fans but quickly proved their commitment through substantial investments in American racing infrastructure.

Toyota Racing Development established facilities in North Carolina and hired experienced NASCAR personnel to accelerate their learning curve. The manufacturer partnered with Joe Gibbs Racing and other teams to develop competitive packages that could challenge established brands. Their systematic approach to data analysis and continuous improvement helped them secure their first Cup Series championship with Martin Truex Jr. in 2017.

Since entering NASCAR, Toyota has won three Cup Series championships and consistently fields competitive cars across all series levels. The manufacturer operates their own engine program and provides extensive technical support to affiliated teams. Toyota’s success demonstrates how dedication to NASCAR’s unique requirements can overcome traditional brand loyalties and establish new competitive benchmarks.

NASCAR Car Safety Innovations That Changed Racing

Safety innovations in NASCAR have revolutionized the sport, protecting drivers while maintaining the high-speed excitement fans love. These groundbreaking technologies emerged from tragedy and transformed racing into the safer sport we see today.

The Introduction of SAFER Barriers

SAFER barriers represent one of the most important safety advances in NASCAR history. Developed by the University of Nebraska following Dale Earnhardt’s fatal crash in 2001, these Steel and Foam Energy Reduction barriers absorb impact energy that would otherwise transfer directly to the driver. The barriers consist of steel tubes backed by energy-absorbing foam, creating a cushioning effect during crashes.

Installation began at Indianapolis Motor Speedway in 2002, and NASCAR mandated their use at all Cup Series tracks by 2005. Traditional concrete walls transfer 100% of crash energy back to the car, while SAFER barriers reduce this transfer by up to 50%. We’ve seen dramatic reductions in serious injuries since their implementation, with drivers walking away from crashes that would have been devastating just decades earlier.

The barriers work by deflecting cars along the wall rather than stopping them abruptly. This progressive deceleration significantly reduces the G-forces experienced by drivers during wall impacts. Track data shows SAFER barriers have prevented countless serious injuries and likely saved multiple lives since their widespread adoption.

HANS Device Implementation

HANS devices became mandatory in NASCAR following Dale Earnhardt’s death from basilar skull fracture in 2001. The Head and Neck Support system prevents the violent forward motion of a driver’s head during sudden deceleration, addressing one of racing’s most deadly injury types. Dr. Robert Hubbard invented this carbon fiber device in the 1980s, but NASCAR didn’t mandate its use until 2001.

The device attaches to a driver’s shoulders and helmet, creating a tether system that limits head movement during crashes. During a frontal impact, the HANS device prevents the head from snapping forward with enough force to cause basilar skull fractures. This injury mechanism had claimed several NASCAR drivers’ lives, including Neil Bonnett and Kenny Irwin Jr.

Implementation wasn’t immediate or universally accepted by drivers initially. Some complained about restricted movement and discomfort during long races. But, the device’s effectiveness became undeniable as drivers began surviving crashes that previously would have been fatal. Today’s HANS devices weigh approximately 1.5 pounds and have saved countless lives across all forms of motorsport.

Carbon Fiber Safety Improvements

Carbon fiber technology transformed NASCAR safety through its exceptional strength-to-weight ratio properties. Modern NASCAR cars incorporate carbon fiber in seat construction, providing superior impact protection while reducing overall vehicle weight. The material’s ability to absorb energy during crashes makes it ideal for safety applications where traditional materials would fail.

Seat manufacturers like Recaro and Sparco now use carbon fiber extensively in NASCAR applications. These seats feature multiple layers of carbon fiber weaving that create a protective cocoon around drivers during impacts. The material’s unique properties allow it to flex and absorb energy rather than transferring it directly to the driver’s body.

Carbon fiber safety improvements extend beyond seating to include steering wheels, dashboard components, and door panels. The material’s lightweight nature allows engineers to add more safety equipment without exceeding weight restrictions. Modern carbon fiber seats can withstand impacts exceeding 60 Gs while maintaining structural integrity, compared to older fiberglass seats that would crack or fail at much lower impact levels.

Racing teams now invest heavily in carbon fiber safety technology, with top-tier seats costing upward of $5,000 each. This investment reflects the material’s proven ability to save lives and reduce injury severity during high-speed crashes.

The Economics Behind Building NASCAR Cars

NASCAR represents one of motorsport’s most expensive endeavors, with financial investments reaching astronomical figures that dwarf most other racing series. We’ll explore the complex financial network that drives this premier racing championship.

Cost Breakdown of a Single Race Car

Building a competitive NASCAR Cup Series car requires an initial investment between $400,000 and $500,000 for the chassis alone. Engines represent the most expensive single component, with each custom-built powerplant costing approximately $100,000 to $150,000 to manufacture and develop.

Teams typically maintain 15 to 20 race-ready chassis throughout the season, creating an inventory worth $6 million to $10 million. Each engine requires rebuilding after every race weekend, adding $15,000 to $25,000 in maintenance costs per event.

Specialized components drive costs even higher across multiple systems. Carbon fiber body panels cost $50,000 to $75,000 per car, while custom-engineered suspension systems add another $40,000 to $60,000. Safety equipment including roll cages, seats, and HANS devices contribute $75,000 to $100,000 to the total build cost.

| Component | Cost Range |

|---|---|

| Chassis | $400,000 – $500,000 |

| Engine | $100,000 – $150,000 |

| Body Panels | $50,000 – $75,000 |

| Safety Equipment | $75,000 – $100,000 |

| Suspension System | $40,000 – $60,000 |

Team Budgets and Sponsorship Requirements

Top-tier NASCAR Cup Series teams operate with annual budgets ranging from $15 million to $25 million per car. Multi-car organizations like Hendrick Motorsports and Joe Gibbs Racing invest $75 million to $100 million annually across their entire racing programs.

Primary sponsors typically invest $10 million to $20 million per season for full-car coverage across all 36 races. Associate sponsors contribute $2 million to $5 million for partial season partnerships, while race-by-race deals range from $200,000 to $500,000 per event.

Personnel costs consume the largest portion of team budgets, with crew chiefs earning $500,000 to $1.5 million annually. Pit crew members receive $150,000 to $300,000 per year, while engineering staff command salaries between $75,000 and $200,000 depending on experience and specialization.

Transportation and logistics add important expenses throughout the racing season. Teams spend $2 million to $4 million annually on hauler operations, fuel costs, and travel expenses for personnel attending all race weekends.

Return on Investment for Manufacturers

Chevrolet, Ford, and Toyota each invest approximately $100 million to $150 million annually in their NASCAR programs, viewing racing as crucial marketing and development platforms. These manufacturers receive substantial returns through increased brand visibility and consumer purchasing decisions.

Studies show NASCAR fans demonstrate 3 to 5 times higher brand loyalty compared to general consumers, translating into measurable sales increases for participating manufacturers. Ford reported a 15% increase in truck sales following successful NASCAR campaigns, while Toyota gained 12% market share growth in key demographics after entering the sport.

Technology transfer from racing to production vehicles generates additional value for manufacturers. Engine management systems, aerodynamic improvements, and safety innovations developed for NASCAR often appear in consumer vehicles within 2 to 4 years. These advancements help justify racing investments through improved product development timelines and competitive advantages.

Television exposure provides quantifiable marketing benefits worth millions of dollars annually. Each manufacturer receives approximately 20 to 30 hours of prime-time television coverage per race weekend, equivalent to $50 million to $100 million in traditional advertising value throughout the season.

Future Innovations in NASCAR Car Technology

NASCAR continues evolving as technology advances and environmental concerns shape motorsports’ future. We’re witnessing the dawn of revolutionary changes that’ll transform racing while preserving the sport’s competitive essence.

Hybrid Engine Possibilities

Hybrid powertrains represent the next frontier in NASCAR car development. We expect NASCAR to introduce hybrid systems by 2026, combining traditional V8 engines with electric motors to enhance performance while reducing emissions. Formula 1 and IndyCar have already demonstrated hybrid technology’s racing viability, producing systems that add instant torque for overtaking and energy recovery during braking.

Manufacturers are developing hybrid units that’ll deliver approximately 100 additional horsepower from electric motors. Teams will manage energy deployment strategically throughout races, creating new tactical dimensions for drivers and crew chiefs. Battery technology advances promise lighter, more efficient power storage systems that won’t compromise NASCAR cars’ signature handling characteristics.

Push to pass systems using hybrid power could revolutionize race strategy dynamics. Drivers will have limited electric boost availability per race, requiring careful deployment timing for maximum competitive advantage. Regenerative braking systems will capture energy during caution periods and heavy braking zones, storing power for crucial racing moments.

Advanced Telemetry Systems

Real time data collection will transform how teams optimize NASCAR car performance during races. We anticipate enhanced sensor networks monitoring engine parameters, tire temperatures, aerodynamic loads, and suspension dynamics with unprecedented precision. Machine learning algorithms will analyze this data instantaneously, providing crews with predictive insights about optimal pit stop timing and setup adjustments.

Biometric monitoring systems will track driver vital signs and fatigue levels throughout races. Teams will receive alerts about driver stress, heart rate patterns, and hydration status, enabling proactive safety interventions. Advanced cockpit displays will present simplified data streams to drivers without overwhelming them during high speed competition.

Predictive maintenance technology will monitor NASCAR cars’ component wear patterns using artificial intelligence. Teams will anticipate mechanical failures before they occur, scheduling part replacements to minimize race disruptions. Cloud based data sharing between manufacturers and teams will accelerate technological development across the entire sport.

Sustainable Racing Initiatives

Alternative fuel development will reshape NASCAR’s environmental footprint while maintaining competitive integrity. We expect NASCAR to introduce renewable fuel blends containing up to 50% sustainable components by 2030. These bio based fuels will produce identical horsepower output while significantly reducing carbon emissions from racing operations.

Carbon fiber recycling programs will transform how teams manage NASCAR car construction materials. Advanced recycling technologies will process crashed car components into new racing parts, creating closed loop manufacturing systems. Teams will track material lifecycles from production through recycling, establishing sustainability metrics for championship points systems.

Solar powered charging stations will support electric systems in hybrid NASCAR cars. Racing facilities will install renewable energy infrastructure to power team operations, reducing the sport’s overall environmental impact. Fan engagement initiatives will highlight sustainability efforts, educating audiences about clean technology applications in high performance motorsports environments.

Electric support vehicle fleets will replace traditional gasoline powered equipment at racing events. Teams will use electric pit carts, haulers, and maintenance vehicles wherever practical. Waste reduction protocols will minimize single use materials, implementing comprehensive recycling programs at all NASCAR sanctioned facilities.

Conclusion

NASCAR cars represent the perfect fusion of cutting-edge technology and raw racing passion. We’ve explored how these machines have evolved from simple stock vehicles into sophisticated engineering marvels that push the boundaries of speed and safety.

The sport’s commitment to innovation continues driving NASCAR forward into an exciting future. From hybrid powertrains to advanced telemetry systems we’re witnessing a transformation that’ll reshape competitive racing.

These extraordinary vehicles embody decades of technological advancement and safety evolution. They’re testament to human ingenuity and our relentless pursuit of automotive excellence on the track.

NASCAR cars will continue inspiring generations of racing enthusiasts and engineers alike. Their legacy extends far beyond the speedway influencing automotive development and capturing imaginations worldwide.

Frequently Asked Questions

What makes NASCAR cars different from regular street cars?

NASCAR cars are purpose-built racing machines with tubular steel space frames, custom-built engines producing 670-750 horsepower, and specialized safety equipment like five-point harnesses and HANS devices. Unlike street cars with unibody construction and passenger comfort features, NASCAR vehicles prioritize performance and driver safety, with body panels serving purely cosmetic functions.

How fast can NASCAR cars go?

NASCAR cars can reach speeds over 200 mph on superspeedways like Daytona and Talladega. Their top speeds vary depending on track type and aerodynamic package, with restrictor plates limiting speeds at certain venues for safety reasons while maintaining competitive racing.

What engines do NASCAR cars use?

NASCAR cars use standardized 5.86-liter naturally aspirated V8 engines with electronic fuel injection. These engines produce 670 horsepower at restrictor plate tracks and 750 horsepower at other venues. All engines must meet strict NASCAR specifications to ensure fair competition across all manufacturers.

How much does it cost to build a NASCAR car?

A single NASCAR car costs between $500,000 to $650,000 to build. The chassis ranges from $400,000-$500,000, engines cost $100,000-$150,000, and additional components add to the total. Teams typically maintain multiple cars and engines, with annual budgets ranging from $15-25 million per car.

What safety features do NASCAR cars have?

NASCAR cars include SAFER barriers, five-point harnesses, HANS devices, carbon fiber seats, fire suppression systems, and reinforced roll cages. These safety innovations have dramatically reduced serious injuries and fatalities, making modern NASCAR racing significantly safer while maintaining high-speed competition.

Which manufacturers compete in NASCAR?

Chevrolet, Ford, and Toyota are the current manufacturers in NASCAR Cup Series. Chevrolet leads with over 40 championships, Ford brings decades of racing heritage and innovation, while Toyota joined in 2007 and quickly became competitive through dedicated engineering and development programs.

How has NASCAR technology evolved over time?

NASCAR has evolved from modified street cars in the 1940s to high-tech racing machines. Key developments include aerodynamic body modifications, restrictor plates, electronic fuel injection, advanced telemetry systems, and comprehensive safety innovations like the Car of Tomorrow safety cage and modern crash barriers.

What are the most iconic NASCAR cars in history?

Richard Petty’s Plymouth Superbird dominated 1970 with innovative aerodynamics, Dale Earnhardt’s black Chevrolet Monte Carlo became legendary for aggressive racing success, and Jeff Gordon’s colorful DuPont Chevrolets revolutionized NASCAR marketing. Each car achieved remarkable performance while leaving lasting cultural impacts on the sport.

What future innovations are coming to NASCAR?

NASCAR plans to introduce hybrid engines by 2026, combining traditional V8s with electric motors for enhanced performance and reduced emissions. Future innovations include advanced telemetry systems, predictive maintenance technology, renewable fuel blends, and sustainable racing initiatives like solar-powered charging stations.

How do NASCAR regulations ensure fair competition?

NASCAR enforces strict specifications for engines, aerodynamics, and safety equipment. All cars must meet identical aerodynamic coefficients, use standardized engines, and follow precise body templates. These regulations ensure competitive balance while allowing manufacturers to maintain brand identity and prioritize driver safety.