Hot rod cars represent the ultimate fusion of American ingenuity and automotive passion. These custom-built machines transform ordinary vehicles into roaring beasts that command attention on every street corner. From their humble beginnings in the 1930s to today’s modern interpretations, hot rods continue to captivate enthusiasts who crave raw power and distinctive style.

We’ve all felt that rush of adrenaline when a perfectly tuned hot rod rumbles past, its chrome gleaming and engine growling with unbridled energy. These aren’t just cars – they’re rolling works of art that showcase the builder’s creativity and mechanical expertise. Whether you’re drawn to classic ’32 Ford roadsters or prefer modern street rods with cutting-edge technology, the hot rod community offers endless possibilities for customization.

The industry of hot rodding isn’t just about speed and style; it’s about preserving automotive history while pushing the boundaries of what’s possible. We’ll explore the essential elements that make these machines legendary.

What Are Hot Rod Cars and Why They’re America’s Ultimate Custom Machines

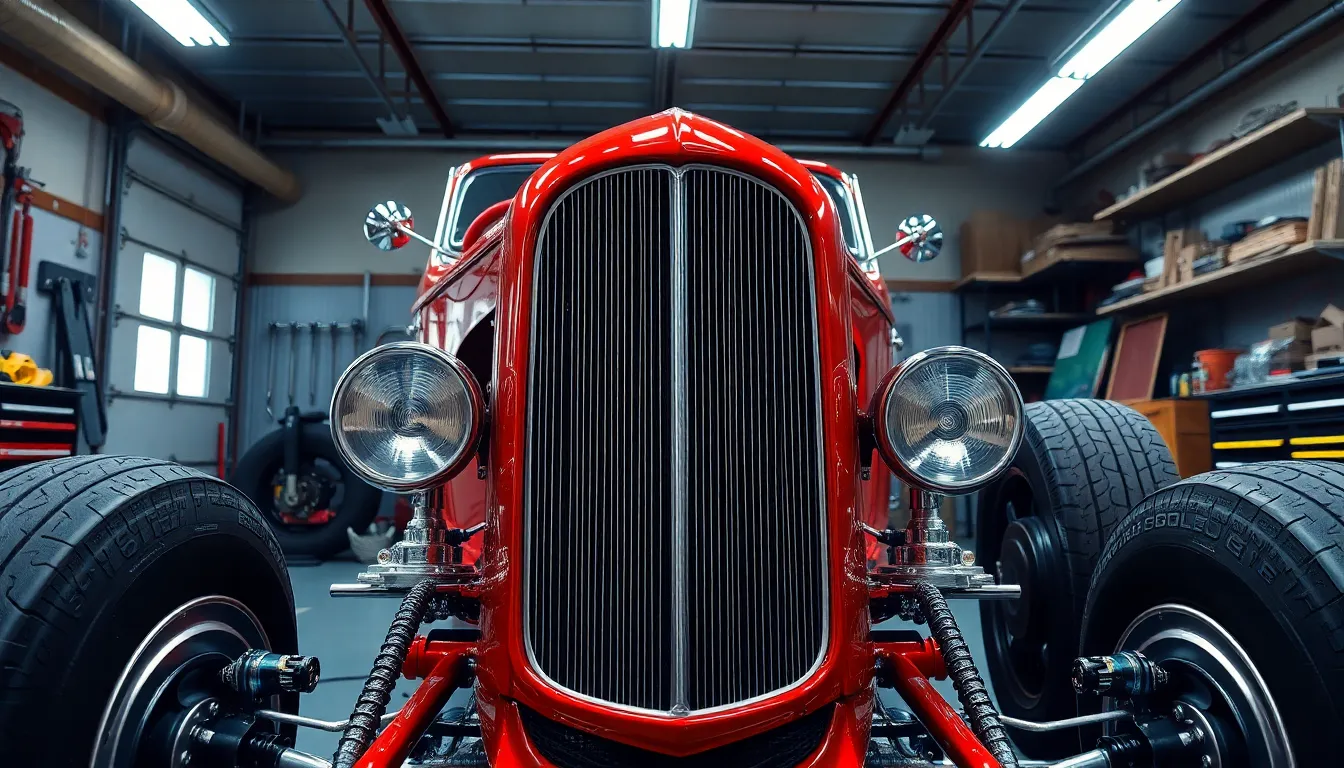

Hot rod cars represent the pinnacle of American automotive customization, blending raw performance with distinctive visual appeal that captures our nation’s rebellious spirit. These modified vehicles typically feature stripped down bodywork, exposed engines, and aggressive styling that prioritizes speed and personality over factory comfort features.

Traditional hot rods emerged from the 1930s California car culture, where young enthusiasts removed fenders, hoods, and unnecessary components from Ford Model Ts and Model As to reduce weight. We see these early builders focusing on maximum power to weight ratios by installing larger V8 engines from newer vehicles into older, lighter chassis.

Modern hot rod construction follows three primary approaches that define the contemporary scene. Street rods maintain vintage aesthetics while incorporating modern safety features like disc brakes, power steering, and updated electrical systems. Traditional hot rods preserve authentic 1930s to 1960s styling with period correct modifications and minimal modern upgrades. Pro street builds push performance boundaries with massive engines, wide rear tires, and drag racing inspired components.

Engine swaps form the heart of hot rod culture, transforming ordinary vehicles into extraordinary machines. Popular combinations include small block Chevrolet V8s in early Ford bodies, big block engines in mid size muscle cars, and modern LS series motors in classic chassis. We observe builders selecting engines based on desired power output, budget constraints, and authenticity preferences.

Visual modifications distinguish hot rods from standard vehicles through deliberate styling choices that emphasize aggression and performance. Chopped tops reduce roof height for a sleeker profile, while channeled bodies sit lower over the frame rails. Exposed engines showcase mechanical artistry through polished components, custom air cleaners, and detailed valve covers that demonstrate craftsmanship.

Hot rod culture embodies American values of individualism and mechanical innovation that resonate across generations. These custom machines allow owners to express personal creativity while participating in a community that values hands on building skills, automotive knowledge, and respect for craftsmanship traditions.

Classic Hot Rod Cars That Started the Movement in the 1930s

Depression era car enthusiasts in Southern California transformed affordable Ford vehicles into the foundation of American hot rod culture. We trace the roots of these legendary machines to three pivotal models that shaped everything we know about hot rodding today.

Ford Model T: The Original Hot Rod Foundation

Model T hot rods emerged from necessity and creativity during the late 1920s and early 1930s. Young mechanics discovered that stripping away the Model T’s heavy body panels and fenders reduced weight dramatically while improving acceleration. California dry lake racers like those at Muroc Dry Lake found that a stripped Model T could achieve speeds exceeding 85 mph with basic engine modifications.

Engine swaps became popular when builders realized the Model T’s four cylinder engine limited performance potential. Chevrolet inline six engines and Ford flathead V8s fit perfectly into the Model T chassis with minimal fabrication work. Racing enthusiasts removed windshields, bumpers, and running boards to create what we now recognize as the classic hot rod silhouette.

Affordability made the Model T accessible to working class builders throughout the 1930s. Used Model Ts sold for as little as $25 to $50, making them the perfect starting point for young hot rodders with limited budgets. This accessibility democratized hot rodding and established the DIY ethos that defines the culture today.

Ford Model A: The Perfect Canvas for Customization

Model A roadsters offered superior styling and engineering compared to their Model T predecessors. Ford produced the Model A from 1927 to 1931 with improved suspension geometry, better brakes, and a more powerful four cylinder engine that produced 40 horsepower. Hot rod builders appreciated the Model A’s cleaner lines and more modern proportions when creating their custom machines.

Chopped tops became synonymous with Model A hot rods during the mid 1930s. Builders removed 3 to 5 inches from the windshield and roof structure to create a lower, more aggressive profile that improved aerodynamics at high speeds. This modification required precise metalworking skills and became a badge of honor among serious hot rod builders.

Racing success at venues like El Mirage Dry Lake established the Model A’s reputation among performance enthusiasts. Modified Model A roadsters consistently posted competitive times against more expensive factory race cars. These victories proved that creativity and craftsmanship could triumph over big budgets, inspiring countless builders to attempt their own projects.

1932 Ford Roadster: The Holy Grail of Hot Rods

1932 Ford roadsters represent the pinnacle of early hot rod design and engineering excellence. Ford’s introduction of the flathead V8 engine in 1932 provided 65 horsepower from the factory, offering significantly more power than previous four cylinder engines. This combination of attractive styling and genuine performance capability made the ’32 Ford the most desirable platform for serious hot rodders.

Henry Ford’s flathead V8 revolutionized hot rod culture when it debuted in the 1932 model year. The new engine featured a one piece block and head design that simplified maintenance while delivering smooth power delivery across the rpm range. Hot rod builders could easily increase power output to over 100 horsepower with basic modifications like dual carburetors and performance camshafts.

Iconic status developed when hot rod pioneers like Tom McMullen and Ak Miller achieved legendary speeds in their 1932 Ford builds. McMullen’s channeled ’32 roadster set multiple records at Bonneville Salt Flats during the late 1930s, reaching speeds exceeding 140 mph. These achievements elevated the 1932 Ford from affordable transportation to the ultimate hot rod platform, establishing its reputation as the holy grail that continues today.

Essential Hot Rod Cars Engine Modifications for Maximum Performance

Building on the foundation of those legendary chassis we’ve explored, the heart of any hot rod transformation lies in its engine modifications. We’ll examine the most impactful upgrades that turn ordinary powerplants into performance monsters.

V8 Engine Swaps That Transform Your Ride

Small block Chevy 350 remains our top recommendation for first-time builders seeking reliable power and extensive aftermarket support. This engine produces 195-300 horsepower in stock form and easily accepts modifications like performance camshafts, aluminum heads, and upgraded intake manifolds. We’ve seen countless builds where the 350’s compact dimensions fit perfectly into Model A frames without major modifications.

Ford 302 Windsor engines offer authentic Ford heritage while delivering impressive performance numbers between 210-290 horsepower. These powerplants maintain the brand loyalty that many traditional hot rod enthusiasts value, and their lightweight construction helps maintain optimal weight distribution. Popular modifications include roller camshafts, performance cylinder heads, and electronic fuel injection conversions.

Big block options like the Chevy 454 provide maximum displacement for builders craving serious torque output exceeding 400 lb-ft. We recommend these engines for larger hot rods such as 1932 Ford coupes or roadsters where the additional weight won’t compromise handling. Modern fuel injection systems make these giants surprisingly manageable for street driving.

LS series engines represent the cutting edge of hot rod swaps, combining modern reliability with compact packaging and impressive power potential. Stock LS1 engines produce 345-350 horsepower while LS3 variants deliver 430 horsepower straight from the factory. These engines accept bolt-on modifications easily and offer excellent fuel economy compared to traditional carbureted setups.

Supercharging and Turbocharging Options

Roots-style superchargers deliver instant throttle response that transforms hot rod acceleration from standstill to 60 mph. We typically see power gains of 40-60% when properly installed on small block engines, with popular units like the 6-71 blower becoming iconic visual statements. These superchargers require minimal computer tuning and work exceptionally well with carbureted setups.

Centrifugal superchargers provide linear power delivery that builds boost progressively through the RPM range. Units from manufacturers like Vortech and Paxton add 100-150 horsepower to stock engines while maintaining excellent drivability. We recommend these systems for builders prioritizing street manners over dramatic visual impact.

Turbocharging systems offer the highest power potential per dollar invested, with single turbo setups easily doubling stock horsepower output. Modern wastegate technology and electronic boost controllers allow precise power management for both street and strip applications. Installation requires more fabrication work than superchargers, but the results justify the additional effort.

Twin turbo configurations maximize power output for serious performance builds targeting 600+ horsepower numbers. We’ve documented builds where properly sized turbos transform mild 350 engines into tire-shredding monsters producing over 700 horsepower. These setups require extensive supporting modifications including upgraded fuel systems and strengthened internals.

Carburetor Upgrades for Better Power Output

Holley double pumper carburetors remain our preferred choice for maximum performance applications requiring crisp throttle response. The 750 CFM and 850 CFM models provide excellent flow characteristics for modified V8 engines producing 350-500 horsepower. We recommend mechanical secondary carburetors for drag racing applications where instant acceleration takes priority.

Edelbrock Performer series carburetors excel in street-driven hot rods where smooth idle quality and fuel economy matter alongside performance. These vacuum secondary units provide progressive power delivery that makes high-performance engines more manageable in traffic. Popular 600 CFM and 750 CFM models work perfectly with mild to moderate engine modifications.

Weber side draft carburetors offer European sophistication for builders seeking unique visual appeal and precise tuning control. Multiple venturi sizes allow custom airflow calibration for exact engine combinations, though installation requires fabricated intake manifolds. We’ve seen impressive results on small displacement engines where individual cylinder tuning maximizes efficiency.

Electronic fuel injection conversions provide modern reliability and tuning flexibility while maintaining hot rod aesthetics through throttle body designs. Systems like Holley Sniper EFI deliver self-learning capabilities that automatically adjust fuel delivery for optimal performance. These upgrades typically increase horsepower by 10-15% while dramatically improving cold start behavior and fuel economy.

Popular Hot Rod Cars Body Styles Every Enthusiast Should Know

Body style selection defines the character and visual impact of every hot rod build. We’ll explore the three foundational body styles that continue to dominate hot rod culture today.

Roadsters: Open Air Freedom and Style

Roadsters deliver the purest hot rod experience with their doorless design and minimal bodywork. These open cockpit vehicles trace their origins to the 1932 Ford Roadster, which became the template for countless builds over nine decades.

Traditional roadsters feature chopped windshields and exposed cockpits that showcase custom interior work. Builders often install tonneau covers behind the seats to create clean lines while maintaining the vehicle’s racing heritage. Popular roadster bases include the 1932 Ford, Model A, and Model T chassis.

Modern roadster builds incorporate advanced materials like fiberglass bodies that reduce weight by 200-300 pounds compared to steel alternatives. Manufacturers like Brookville Roadster and American Speed offer complete reproduction bodies that maintain authentic proportions while improving durability.

Track nose roadsters represent the most aggressive styling variation with their pointed front ends and exposed suspension components. These builds originated from dry lakes racing in California and feature aluminum belly pans that smooth airflow underneath the vehicle.

Coupes: Sleek Lines with Serious Attitude

Coupes combine enclosed comfort with aggressive hot rod styling through their distinctive sloped rooflines and compact proportions. The 1932 Ford Coupe established this body style as a hot rod favorite with its perfect balance of practicality and visual appeal.

Three window coupes offer the most iconic hot rod silhouette with their small rear windows and dramatically chopped tops. Builders typically chop the roof 3-5 inches to create the characteristic low, menacing stance that defines traditional hot rod proportions.

Five window coupes provide improved visibility while maintaining classic hot rod appeal through their additional side windows. These builds work particularly well for daily drivers who need better sight lines without sacrificing the hot rod aesthetic.

Modern coupe builds often feature steel reproduction bodies from companies like Brookville Roadster and United Pacific that offer improved fit and finish over original 1930s bodywork. Advanced welding techniques and precision manufacturing ensure these bodies accept modern drivetrains without extensive modifications.

Sedans: Four Door Hot Rod Practicality

Sedans represent the practical side of hot rod culture while maintaining aggressive styling and performance capabilities. Four door hot rods emerged as families wanted to enjoy hot rod culture without sacrificing passenger space or daily usability.

Traditional sedan builds focus on 1932-1934 Ford models that offer substantial interior room while accepting modern drivetrain swaps. These vehicles typically feature chopped tops ranging from 2-4 inches to improve proportions without compromising headroom for rear passengers.

Sleeper sedans disguise serious performance potential behind seemingly stock exterior appearances. Builders install powerful modern engines like LS series V8s while maintaining original paint schemes and trim pieces that fool unsuspecting observers.

Pro street sedans showcase extreme modifications with tubbed rear ends and massive rear tires that announce their performance intentions. These builds often feature roll cages and racing seats that transform family cars into strip ready machines capable of sub 10 second quarter mile times.

Best Hot Rod Cars Brands and Manufacturers Today

When building hot rods today, three American manufacturers consistently deliver the best foundation vehicles and components for serious builders.

Ford: The Timeless Hot Rod Choice

Ford remains the undisputed king of hot rod culture, providing builders with legendary platforms that define automotive customization. We see Ford’s dominance in every major hot rod category, from their classic 1932 roadsters to modern Mustang donations for contemporary builds.

Builders gravitate toward Ford because their vehicles offer exceptional modification potential and parts availability. The company’s extensive aftermarket support means we can source everything from reproduction body panels to complete chassis kits without breaking our budgets.

Current Ford models like the Mustang GT and F-150 provide excellent donor platforms for modern hot rod projects. These vehicles deliver robust V8 engines, strong transmissions, and proven suspension components that translate perfectly to custom builds.

Ford’s Coyote 5.0L engine has become increasingly popular among hot rod builders seeking reliable modern power. This naturally aspirated V8 produces 460+ horsepower in stock form and responds exceptionally well to modifications like cold air intakes, exhaust systems, and tuning upgrades.

Chevrolet: Modern Power Meets Classic Style

Chevrolet offers hot rod builders an unmatched combination of cutting edge technology and traditional American muscle car DNA. We consistently recommend Chevy platforms for builders who want the latest performance innovations wrapped in classic styling cues.

General Motors’ LS and LT engine families represent the gold standard for modern hot rod powerplants. These engines deliver incredible power density, outstanding reliability, and massive aftermarket support that makes customization straightforward and affordable.

Modern Chevrolet Camaro and Corvette platforms provide builders with industry class suspension technology and aerodynamic efficiency. The Camaro’s independent rear suspension transfers easily to custom chassis applications, while Corvette components offer track proven performance capabilities.

Chevy’s supercharged LT4 and LT5 engines push the boundaries of naturally aspirated performance. These factory forced induction systems produce 650+ horsepower and provide builders with turnkey answers for serious street performance applications.

Chrysler: HEMI Powered Hot Rod Excellence

Chrysler brings legendary HEMI power to modern hot rod construction, offering builders access to some of America’s most powerful production engines. We appreciate how Chrysler combines old school muscle car heritage with contemporary engineering excellence.

The modern 392 and 485 cubic inch HEMI engines deliver massive torque figures that transform hot rod performance characteristics. These engines produce 485+ horsepower in naturally aspirated form and respond dramatically to basic modifications like headers, intake systems, and ECU tuning.

Dodge Challenger and Charger platforms provide excellent starting points for builders seeking modern muscle car foundations. These vehicles offer spacious engine bays, robust drivetrains, and aggressive styling that translates perfectly to custom hot rod applications.

Chrysler’s supercharged Hellcat powertrain represents the pinnacle of factory hot rod performance. This combination produces 707+ horsepower and gives builders access to proven forced induction technology that would cost thousands more in aftermarket form.

Hot Rod Cars Safety Features and Legal Requirements

Modern hot rod enthusiasts must balance performance aspirations with essential safety requirements. Legal compliance ensures our builds remain street legal while protecting occupants during high-performance driving scenarios.

Roll Cage Installation for Track Safety

Racing venues require certified roll cage protection for hot rods exceeding exact power thresholds. NHRA mandates roll bars for vehicles running quarter-mile times faster than 11.50 seconds, while SCCA events typically require full cage systems for open-wheel configurations. Professional fabricators use DOM (Drawn Over Mandrel) tubing with 0.120-inch wall thickness for optimal strength-to-weight ratios.

Proper installation techniques ensure maximum protection during rollover incidents. We recommend welding cages directly to the frame rails rather than using bolt-in systems for serious track applications. Door bars positioned at shoulder height provide crucial side-impact protection, while diagonal braces distribute crash forces throughout the structure. SFI-certified padding covers all potential contact points to prevent driver injuries during collisions.

Street-driven hot rods often incorporate removable roll bar systems for versatility. These configurations allow daily driving comfort while providing track day protection when needed. Bolt-in designs must meet exact torque specifications and include reinforcement plates to prevent frame damage during installation.

Updated Braking Systems for Modern Performance

Four-wheel disc brake conversions deliver stopping power matching modern hot rod acceleration capabilities. Wilwood and Baer Engineering offer complete brake packages featuring 11-inch to 14-inch rotors with four or six-piston calipers. These systems reduce stopping distances by 30-40% compared to original drum brake configurations while providing consistent performance during repeated hard stops.

Power brake boosters enhance pedal feel for drivers transitioning from manual systems. Vacuum-assisted boosters require engine vacuum or electric pump systems to function properly with high-performance camshafts. Hydroboost systems use power steering pressure as an alternative for engines producing insufficient vacuum.

Proportioning valves balance front and rear brake bias for optimal stopping performance. Adjustable units allow fine-tuning based on weight distribution and tire compound selection. Rear disc brake conversions often require proportioning valve adjustments to prevent premature rear wheel lockup during emergency stops.

| Brake System Component | Original Equipment | Modern Upgrade | Performance Improvement |

|---|---|---|---|

| Front Brakes | 9-inch drums | 12-inch disc with 4-piston caliper | 35% shorter stopping distance |

| Rear Brakes | 10-inch drums | 11-inch disc with 2-piston caliper | Improved fade resistance |

| Brake Lines | Single circuit | Dual circuit with braided steel | Enhanced safety and pedal feel |

| Master Cylinder | 1-inch bore | 1.125-inch bore with reservoir | Better fluid capacity |

Lighting and Visibility Compliance Standards

DOT-approved headlights ensure legal street operation while maintaining hot rod aesthetics. LED conversion kits provide modern lighting performance within vintage housings, delivering 3,000-4,000 lumens compared to 1,200 lumens from halogen bulbs. Proper aim adjustment prevents blinding oncoming traffic while maximizing road illumination.

Turn signal systems must meet federal visibility requirements for legal registration. Amber front indicators and red rear signals require minimum candlepower ratings and exact flash rates between 60-120 cycles per minute. Electronic flasher units accommodate LED bulbs without hyperflashing issues common with thermal flashers.

Brake light configurations vary by state but generally require dual rear-mounted lights. Third brake lights became mandatory for vehicles manufactured after 1986, though many states exempt hot rods based on original model year designations. Side marker lights enhance visibility and are required on vehicles over 80 inches in length.

Mirror placement standards ensure adequate rear visibility for safe operation. Left-side exterior mirrors are federally mandated, while right-side mirrors become required when rear window visibility is obstructed. Convex mirrors provide wider viewing angles but may distort distance perception for inexperienced drivers.

Building Your First Hot Rod Cars Project on Any Budget

Starting your first hot rod cars project doesn’t require a fortune or decades of experience. We’ll guide you through three distinct budget approaches that deliver exceptional results regardless of your financial constraints.

Budget-Friendly Starter Hot Rod Options

Street rod builds under $15,000 offer the perfect entry point for first time builders looking to join the hot rod community. We recommend starting with a complete donor vehicle like a 1970s Chevrolet Nova or Ford Maverick, which typically costs between $3,000 to $5,000 in running condition. These platforms provide solid foundations with readily available parts and extensive online support communities.

Engine swaps using salvage yard components can deliver impressive power gains without breaking your budget. A small block Chevy 350 from a pickup truck costs around $500 to $800, while a Ford 302 Windsor runs approximately $400 to $700. We’ve seen builders achieve 300+ horsepower using rebuilt heads, a performance camshaft, and basic carburetor upgrades for under $2,000 total investment.

DIY bodywork and paint projects represent important savings when you’re willing to learn new skills. Primer and single stage paint jobs cost between $800 to $1,500 in materials, compared to $8,000 to $15,000 for professional work. We suggest practicing on practice panels first, then tackling straightforward modifications like installing a cowl hood or adding racing stripes.

Suspension upgrades from aftermarket suppliers provide substantial handling improvements at reasonable prices. Front coilover conversion kits range from $600 to $1,200, while rear leaf spring upgrades cost $300 to $600. We’ve found that these modifications transform the driving experience more dramatically than expensive interior updates.

Mid-Range Builds with Professional Results

Complete frame off restorations between $25,000 to $45,000 deliver show quality results when executed properly. We typically allocate 40% of the budget toward engine and drivetrain components, 30% for bodywork and paint, and 30% for suspension, brakes, and interior upgrades. This distribution ensures balanced performance across all vehicle systems.

Crate engine installations from major manufacturers provide reliability and warranty coverage that salvage yard builds cannot match. A GM LS3 crate engine costs approximately $8,500, while Ford’s 5.0L Coyote runs around $9,200. We recommend budgeting an additional $3,000 to $5,000 for installation, wiring harnesses, and supporting modifications.

Professional paint and bodywork services elevate mid range builds to concours level appearance standards. Base coat clear coat paint jobs range from $8,000 to $15,000 depending on color complexity and body modifications. We’ve observed that investing in quality bodywork yields better long term satisfaction than cutting corners on appearance details.

Modern suspension and brake system upgrades ensure your hot rod handles like a contemporary performance car. Independent front suspension conversions cost $4,500 to $8,000, while four wheel disc brake systems range from $2,500 to $4,500. We prioritize these safety related improvements before focusing on cosmetic enhancements.

High-End Custom Hot Rod Investments

Full custom chassis fabrication projects exceeding $75,000 represent the pinnacle of hot rod construction artistry. We work with specialized builders who create bespoke frames using modern CAD design and precision welding techniques. These builds typically require 18 to 24 months completion time and involve extensive collaboration between multiple craftsmen.

Supercharged big block engine combinations deliver incredible power figures that demand respect and skill to manage safely. A blown 454 Chevy or 440 Mopar can produce 600+ horsepower while maintaining streetable characteristics. We’ve seen complete engine packages cost $25,000 to $40,000 including forged internals, custom camshafts, and professional tuning services.

Show quality paint and interior appointments rival exotic sports cars in terms of craftsmanship and attention to detail. Multi stage paint processes with custom graphics cost $20,000 to $35,000, while hand stitched leather interiors range from $8,000 to $15,000. We insist on using premium materials like German leather and aircraft grade aluminum trim pieces.

Advanced electronic systems and modern conveniences integrate seamlessly into traditional hot rod aesthetics through careful planning and execution. Digital dashboard conversions cost $3,500 to $6,500, while complete air conditioning systems run $2,800 to $4,200. We balance modern functionality with period appropriate styling to maintain authentic hot rod character.

Hot Rod Cars Shows and Events Worth Attending

We’ve covered the builds and modifications that make hot rods special, but experiencing these machines alongside fellow enthusiasts at major shows elevates the entire culture.

NSRA Street Rod Nationals East and West

NSRA Street Rod Nationals East showcases over 10,000 hot rods annually in York, Pennsylvania each June. This premier event brings together builders from across the eastern United States to display traditional street rods built from 1948 and earlier vehicles. We witness everything from pristine Model A roadsters to radical 1932 Ford coupes competing for prestigious awards in categories like Traditional, Modified, and Street Machine divisions.

NSRA Street Rod Nationals West draws 8,000+ participants to Pueblo, Colorado every August. Mountain scenery provides a stunning backdrop for the western celebration of hot rod culture. Vendors offer rare parts, custom fabrication services, and restoration supplies while swap meets feature hard to find components for vintage Ford and Chevrolet platforms.

Registration typically opens in January for both events with entry fees around $55 per vehicle. Early registration ensures prime parking spots and preferred camping locations. Both nationals feature driving events, tech seminars, and manufacturer displays showcasing the latest performance parts and restoration techniques.

Goodguys Rod and Custom Shows

Goodguys hosts 20+ events annually across the United States attracting 60,000+ hot rod enthusiasts per season. These shows welcome pre-1973 vehicles and include everything from traditional hot rods to modern muscle cars. We see incredible diversity ranging from flathead powered 1932 roadsters to LS swapped 1970 Chevelles competing in various judged categories.

Columbus, Ohio and Nashville, Tennessee serve as flagship Goodguys events with 4,000+ registered vehicles each. These massive gatherings feature autocross competitions, burnout contests, and vendor midways spanning multiple city blocks. Professional builders showcase their latest creations while amateur enthusiasts display weekend garage projects side by side.

Autocross events provide competitive driving opportunities for street legal hot rods throughout each weekend. Timed runs through cone courses test handling capabilities and driver skills. Categories include Street Machine, Pro Touring, and Traditional Hot Rod divisions with awards recognizing both performance and presentation excellence.

Local Hot Rod Club Gatherings and Cruise-Ins

Weekly cruise nights offer accessible entry points for new hot rod enthusiasts throughout spring and summer months. Local establishments like drive in restaurants, shopping centers, and community parks host these casual gatherings every Tuesday through Saturday across most metropolitan areas. We find these events perfect for showcasing recent builds and connecting with regional craftsmen.

Monthly club meetings provide technical knowledge sharing and project planning opportunities for serious builders. Established organizations like Early Ford V8 Club chapters and Street Rod associations offer restoration advice, parts sourcing assistance, and group purchasing power for expensive components. Members share fabrication techniques, paint booth time, and specialized tools reducing individual project costs significantly.

Annual club sponsored events generate funds for local charities while celebrating hot rod culture within communities. Car shows, poker runs, and touring events raise thousands of dollars for children’s hospitals, veterans organizations, and automotive education programs. These gatherings strengthen relationships between hot rod enthusiasts and local businesses while promoting positive community engagement.

Maintaining and Preserving Your Hot Rod Cars Collection

Preserving your hot rod investment requires consistent care and strategic planning. We’ll explore essential maintenance practices that keep these automotive treasures performing at their peak while maintaining their value for generations.

Regular Maintenance Schedules for Optimal Performance

Engine maintenance schedules demand more frequent attention than standard vehicles due to modified components and higher performance demands. We recommend checking oil levels every 500 miles and performing complete oil changes every 2,000-3,000 miles, especially with high-performance engines running synthetic oils. Coolant systems require monthly inspections since custom radiators and modified cooling setups can develop leaks or blockages more readily than stock configurations.

Carburetor maintenance becomes crucial for hot rods equipped with traditional fuel delivery systems. We suggest cleaning carburetor jets and adjusting float levels every 5,000 miles to maintain optimal fuel mixture ratios. Fuel filters need replacement every 10,000 miles to prevent debris from reaching these sensitive components. Electronic fuel injection systems require less frequent maintenance but benefit from annual fuel system cleaning services.

Brake system inspections should occur every 3,000 miles due to the increased stopping demands of powerful engines. We prioritize checking brake fluid levels, pad thickness, and rotor condition since hot rod performance often exceeds original design parameters. Suspension components require quarterly inspections, particularly custom setups with aftermarket shocks, springs, and bushings that may wear differently than factory parts.

Electrical system maintenance includes monthly battery terminal cleaning and annual wiring harness inspections. We focus on custom electrical modifications, aftermarket gauges, and performance ignition systems that can develop connection issues over time. Spark plug replacement intervals vary based on engine modifications but typically range from 10,000-15,000 miles for performance applications.

Proper Storage Techniques for Long-Term Preservation

Climate controlled storage provides the foundation for preserving hot rod cars during extended periods of non-use. We recommend maintaining temperatures between 60-70°F with humidity levels below 50% to prevent rust formation and paint degradation. Concrete floors require moisture barriers or car covers with breathable materials to prevent condensation damage.

Fuel system preparation involves adding fuel stabilizers and filling tanks to prevent moisture accumulation during storage periods exceeding 30 days. We drain carburetors completely or use fuel shut-off valves to prevent gum formation in fuel bowls. Modern fuel injection systems benefit from running engines monthly during storage to circulate treated fuel through the system.

Battery maintenance during storage requires disconnecting terminals and using battery tenders to maintain proper charge levels. We recommend removing batteries entirely for storage periods exceeding 90 days, storing them in temperature-controlled environments away from concrete surfaces. Lead-acid batteries need monthly voltage checks while lithium units require less frequent monitoring.

Tire protection involves inflating to maximum recommended pressure and using tire cradles or jack stands to prevent flat spots during long-term storage. We rotate tire positions monthly if the vehicle remains on wheels and inspect for cracking or weather damage. Covering tires with UV-protective materials prevents rubber degradation from fluorescent lighting exposure.

Fluid maintenance includes changing engine oil before storage periods exceeding 60 days since used oil contains contaminants that promote corrosion. We recommend circulating fresh coolant through the system and checking brake fluid for moisture contamination. Transmission and differential fluids should be changed annually regardless of mileage on stored vehicles.

Finding Quality Parts and Restoration Services

Specialized hot rod suppliers offer authentic restoration parts and performance upgrades specifically designed for classic platforms. We recommend establishing relationships with companies like Speedway Motors, Summit Racing, and Jegs that stock extensive inventories of Ford, Chevy, and Mopar components. Local hot rod shops often provide personalized service and can source rare parts through established networks.

Restoration service evaluation requires examining previous work examples, checking customer references, and verifying insurance coverage before committing to major projects. We suggest visiting shops during active restoration projects to observe work quality, cleanliness, and organization standards. Certified restoration specialists typically charge $75-125 per hour but deliver professional results that preserve investment value.

Parts authentication becomes critical when sourcing original components for traditional hot rod builds. We recommend using date code verification, casting number cross-references, and manufacturer markings to confirm authenticity. Reproduction parts from companies like Brookville Roadster and Danchuk provide reliable alternatives when original components aren’t available or economically feasible.

Service documentation helps maintain accurate maintenance records and preserves warranty coverage for restoration work. We maintain detailed logs of all parts sources, service dates, and modification details for insurance and resale purposes. Digital photo documentation before, during, and after restoration work provides valuable reference material for future maintenance needs.

Network resources within the hot rod community offer invaluable connections to quality parts and services. We participate in forums like The H.A.M.B. (Hokey Ass Message Board) and local car club meetings where experienced builders share vendor recommendations and warn about problematic suppliers. These relationships often lead to access to rare parts and referrals to trustworthy craftsmen.

Conclusion

Hot rod culture represents far more than automotive customization – it’s a living testament to American ingenuity and craftsmanship. We’ve witnessed how these remarkable machines continue to evolve while honoring their rich heritage from the 1930s California car scene.

Whether you’re drawn to budget-friendly builds or high-end custom projects there’s a place for every enthusiast in this vibrant community. The combination of classic styling modern performance and endless personalization options ensures hot rods remain relevant for future generations.

We encourage you to connect with local clubs attend car shows and experience firsthand what makes this culture so enduring. Hot rods aren’t just cars – they’re rolling expressions of passion creativity and the timeless American spirit of innovation.

Frequently Asked Questions

What exactly is a hot rod car?

A hot rod car is a custom-built vehicle that represents the pinnacle of American automotive customization. These machines combine raw performance with distinctive visual appeal, typically featuring modified engines, chopped bodies, and aggressive styling. Hot rods blend American creativity with automotive passion, transforming ordinary cars into eye-catching performance vehicles that embody the nation’s rebellious spirit and individualistic values.

When did hot rod culture begin?

Hot rod culture originated in 1930s California, where automotive enthusiasts began modifying Ford Model Ts and Model As for better power-to-weight ratios. The movement gained significant momentum with the introduction of the 1932 Ford Roadster, which featured the revolutionary flathead V8 engine. This era established the foundation for modern hot rod building and created a community centered around creativity and craftsmanship.

What are the main types of hot rod builds?

Modern hot rod construction falls into three primary categories: street rods, traditional hot rods, and pro street builds. Street rods focus on drivability with modern amenities, traditional hot rods maintain authentic vintage styling and components, while pro street builds emphasize maximum performance with drag racing-inspired modifications. Each approach offers unique characteristics and appeals to different builder preferences.

Which classic cars make the best hot rod foundations?

The Ford Model T, Model A, and 1932 Ford Roadster are considered the holy grail foundations for hot rod builds. The Model T offers affordability and simplicity, the Model A provides superior styling and engineering, while the 1932 Ford Roadster combines powerful V8 performance with iconic design. These models established the templates that continue to inspire builders today.

What are popular engine swap options for hot rods?

Popular engine swaps include the small block Chevy 350 and Ford 302 Windsor for reliable power and extensive aftermarket support. Big block options like the Chevy 454 provide serious torque, while modern LS series engines offer outstanding reliability and power potential. These engines provide the foundation for significant performance improvements in hot rod builds.

What body styles are most common in hot rod culture?

The three foundational hot rod body styles are roadsters, coupes, and sedans. Roadsters feature open-air design with chopped windshields, coupes combine sleek lines with aggressive styling, and sedans offer practicality without sacrificing performance. Each style reflects different expressions of hot rod culture while maintaining the core elements of creativity and performance.

Which manufacturers are best for modern hot rod builds?

Ford, Chevrolet, and Chrysler are the top American manufacturers for hot rod builds. Ford offers legendary platforms like the Mustang GT with extensive aftermarket support. Chevrolet provides cutting-edge LS and LT engine families with outstanding performance. Chrysler delivers powerful HEMI engines that produce impressive torque and horsepower for modern hot rod construction.

What safety features are required for hot rods?

Modern hot rods require proper roll cage installations for track safety, meeting NHRA and SCCA specifications. Four-wheel disc brake conversions improve stopping power significantly. DOT-approved lighting systems including headlights and turn signals must meet federal regulations. Safety equipment varies based on intended use, with track cars requiring more extensive protection than street-driven vehicles.

How much does it cost to build a hot rod?

Hot rod builds vary widely in cost. Budget-friendly builds under $15,000 use complete donor vehicles and salvage yard components. Mid-range builds between $25,000-$45,000 balance professional services with quality components. High-end custom builds exceeding $75,000 feature full custom fabrication, supercharged engines, and luxury appointments representing the pinnacle of hot rod artistry.

How do I maintain and preserve a hot rod?

Hot rod maintenance requires consistent care including regular engine checks, brake inspections, and electrical system upkeep. Climate-controlled storage prevents damage during non-use periods. Quality parts sourcing and authentic components preserve value and performance. Proper fuel system preparation and routine maintenance schedules tailored to modified vehicles ensure longevity and optimal performance.