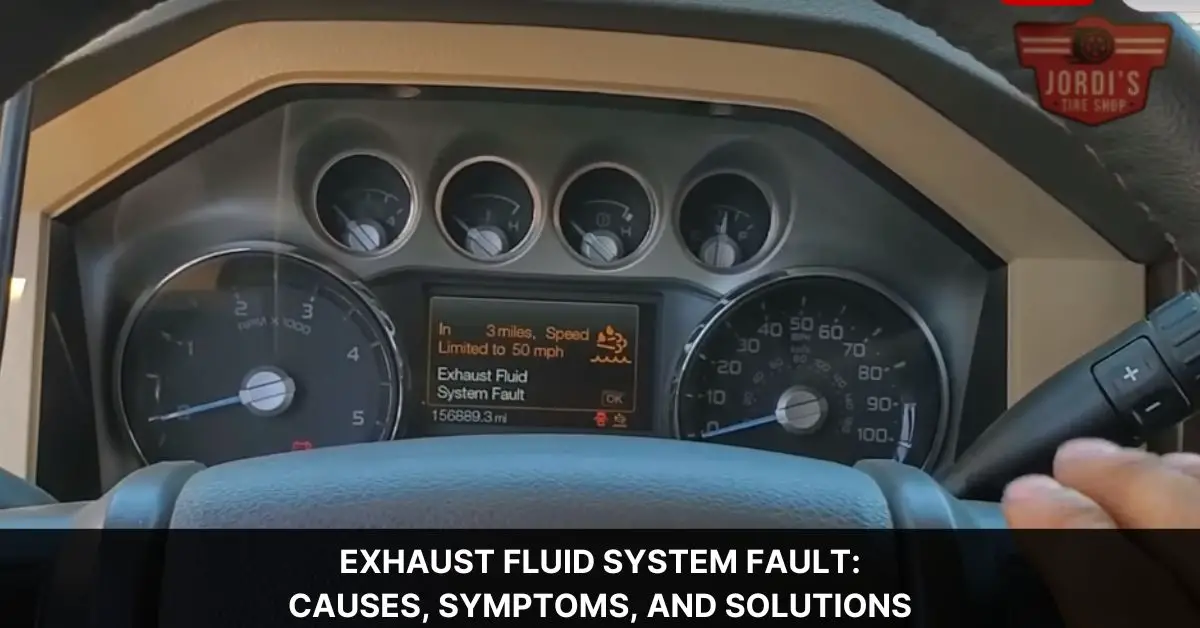

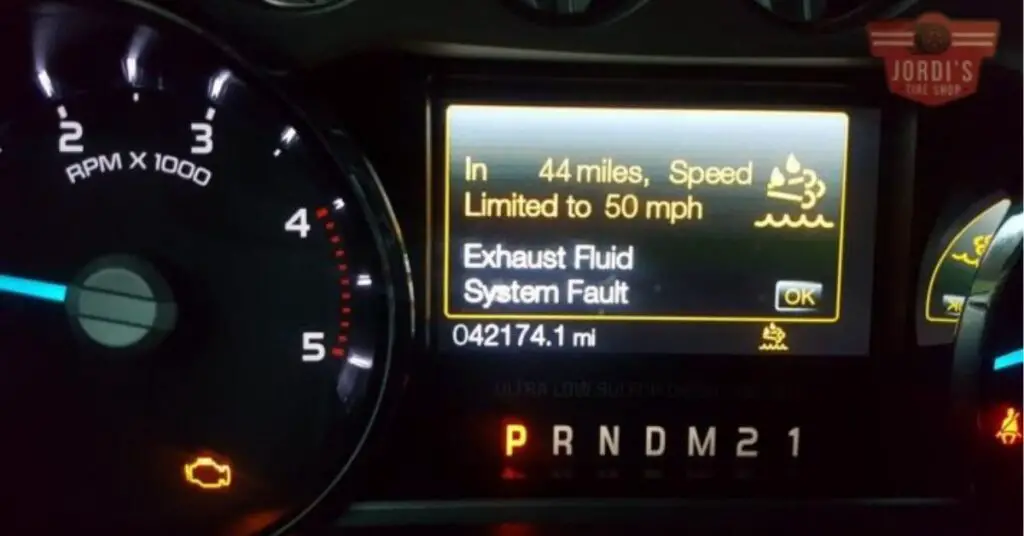

Have you ever found yourself cruising down the highway, only to be greeted by a sudden warning light on your dashboard indicating an exhaust fluid system fault? If so, you’re not alone. This issue, while not uncommon, can throw a wrench into your day, leaving you wondering about the severity of the problem and how quickly it needs to be addressed.

We’ve all been there, scratching our heads, trying to decipher what exactly an exhaust fluid system fault means for our vehicle’s performance and, more importantly, our safety. It’s a situation that calls for a bit of insight, and that’s exactly what we’re here to provide. Let’s dive into the nitty-gritty of what this fault means, why it happens, and how you can tackle it head-on, ensuring your ride remains smooth and uninterrupted.

Understanding Exhaust Fluid System Faults

Continuing from where we left off, understanding exhaust fluid system faults plays a vital role in maintaining vehicle performance and safety. An exhaust fluid system fault, typically indicated by a dashboard warning light, signals an issue with the vehicle’s selective catalytic reduction (SCR) system. This system uses Diesel Exhaust Fluid (DEF) to reduce emissions of nitrogen oxides (NOx), which are harmful pollutants.

The SCR system is a key component in modern diesel engines, ensuring they meet stringent environmental regulations. DEF, a mixture of urea and deionized water, reacts with NOx in the exhaust, converting it into nitrogen and water vapor, which are harmless. Hence, when the system encounters a fault, it could lead to increased emissions and, if not addressed, might impair the vehicle’s functionality or lead to a shutdown scenario.

Here’s a breakdown of common reasons behind exhaust fluid system faults:

- Low DEF Levels: Running low on DEF is a primary cause of exhaust fluid system faults. Vehicles typically warn drivers when DEF levels drop below a certain threshold, allowing time for replenishment before system performance is compromised.

- Quality of DEF: Using DEF that does not meet the manufacturer’s specifications can trigger system warnings. Contaminated or improperly stored DEF can degrade over time, losing its efficacy.

- Sensor Failures: The SCR system relies on sensors to monitor NOx levels and DEF consumption. Faulty sensors can provide incorrect readings, leading to unwarranted fault warnings.

- Malfunctions in the SCR System: Components of the SCR system, such as the injector or the catalytic converter, might fail, disrupting the normal operation and efficiency of the system.

Addressing these issues promptly can prevent further complications. It usually involves refilling the DEF tank, replacing sensors, or repairing specific components of the SCR system. By keeping an eye out for these common faults and understanding their implications, we can ensure our vehicles remain both efficient and environmentally friendly.

Causes of Exhaust Fluid System Faults

Building on the importance of recognizing and addressing exhaust fluid system faults, we delve into the common causes that lead to these issues, focusing on parts and conditions within the selective catalytic reduction (SCR) system. Identifying these causes helps in quicker diagnostics and efficient resolution, ensuring our vehicles maintain optimal performance while adhering to emission standards.

- Low Diesel Exhaust Fluid (DEF) Levels: Vehicles require a certain level of DEF to function correctly. Running on low DEF levels can trigger system warnings, indicating it’s time for a refill. Maintenance routines must include checking DEF levels to avoid such faults.

- Poor DEF Quality: Not all DEF solutions are created equal. Using DEF that doesn’t meet the manufacturer’s specifications can lead to system faults. The wrong concentration or contaminated DEF can impair the SCR’s efficiency, necessitating the use of high-quality DEF.

- DEF Contamination: DEF is highly susceptible to contamination from direct exposure to foreign substances. Even small amounts of dirt or water in the DEF tank can cause significant problems, emphasizing the need for clean handling practices.

- Failed Sensors: The SCR system relies on various sensors to monitor levels and efficiencies, such as the DEF level sensors and NOx sensors. Faulty sensors can send incorrect signals, leading to unnecessary alerts or overlooked maintenance needs.

- Malfunctioning SCR Components: Components within the SCR system, like the DEF injector or the SCR catalyst, can fail due to wear and tear or defects. Such malfunctions disrupt the normal operation of the exhaust fluid system, indicating a need for prompt repairs or replacements.

- Software Issues: Occasionally, the software governing the SCR system may encounter glitches that lead to false alarms or system malfunctions. Software updates or resets by professional technicians can resolve these issues, restoring system functionality.

Understanding these common causes enhances our ability to maintain the SCR system effectively, ensuring that our vehicles remain efficient and environmentally friendly. Regular maintenance and prompt attention to any dashboard warnings can prevent more significant issues down the line, safeguarding both vehicle performance and compliance with emission standards.

Impact of Ignoring Exhaust Fluid System Faults

Ignoring exhaust fluid system faults, particularly within the selective catalytic reduction (SCR) system, leads to several negative outcomes that can affect both the vehicle’s performance and the environment. These consequences highlight the importance of timely attention to any identified issues.

Increased Emissions: The primary function of the SCR system is to reduce nitrogen oxides (NOx) emissions. If faults in the exhaust fluid system go unaddressed, our vehicles emit higher levels of NOx, contributing to air pollution and negatively impacting air quality. Such emissions are harmful to the environment and can lead to health issues in humans and wildlife.

Reduced Fuel Efficiency: An efficiently running exhaust fluid system contributes to optimal fuel economy. Faults within the system can decrease this efficiency, leading to increased fuel consumption. This not only means more frequent stops at the fuel station but also higher running costs over time.

Possible Vehicle Downtime: In some instances, ignoring exhaust fluid system faults can lead to the vehicle entering a reduced power mode, commonly referred to as “limp mode,” to prevent further damage. This mode significantly restricts vehicle performance and can lead to complete vehicle shutdown if not addressed promptly. Such situations result in unexpected downtime and potentially costly repairs.

Damage to Vehicle Components: Continuous operation of a vehicle with unresolved exhaust fluid system faults can lead to further damage to the SCR system and related components. Repairing or replacing these components can be significantly more expensive than addressing the initial faults.

Non-Compliance with Emission Standards: Vehicles are subject to emission standards that aim to minimize their environmental impact. Ignoring exhaust fluid system faults can lead to non-compliance with these standards, potentially resulting in fines and restrictions on vehicle use in certain areas.

Understanding the impact of ignoring exhaust fluid system faults, we can see the importance of regular maintenance and prompt action when issues arise. Not only does this ensure vehicle efficiency and compliance with emission standards, but it also supports broader environmental protection efforts.

Troubleshooting Exhaust Fluid System Faults

Addressing exhaust fluid system faults promptly plays a crucial role in maintaining vehicle performance, reducing emissions, and avoiding potential damage to the selective catalytic reduction (SCR) system. Here are effective steps to troubleshoot common issues related to diesel exhaust fluid (DEF) systems:

Checking DEF Levels and Quality

- Inspect DEF Levels: Ensure that DEF tank levels are adequate since low DEF levels can trigger system faults.

- Assess DEF Quality: Poor quality or contaminated DEF can cause SCR system issues. If suspected, replace the existing fluid with fresh, high-quality DEF.

Evaluating System Components

- Examine DEF Injector: Look for blockages or damage that could impede DEF flow into the SCR system.

- Inspect SCR Catalyst: Check for signs of physical damage or excessive soot, which may indicate malfunction.

- Check for Leaks: Identify and fix any leaks in the DEF supply lines or SCR components to prevent system pressure loss.

Testing Sensors and Electrical Components

- Evaluate Sensors: Faulty temperature, NOx, and level sensors can provide incorrect data, leading to system errors. Test these sensors and replace if faulty.

- Inspect Wiring: Check the wiring harness for signs of wear, damage, or corrosion, and repair or replace as necessary.

Software Assessment and Updates

- Update ECU Software: Ensure the engine control unit (ECU) software is up to date. Manufacturers occasionally release updates to improve system performance and address known issues.

- Perform Diagnostic Tests: Use a diagnostic scan tool to read fault codes. This can pinpoint specific components or systems needing attention.

- Consult a Specialist: If troubleshooting does not resolve the issue, seek assistance from a professional mechanic or dealership. They have specialized tools and expertise to accurately diagnose and repair exhaust fluid system faults.

Following these steps, we can effectively identify and fix most exhaust fluid system faults, maintaining our vehicle’s operational efficiency and environmental compliance.

Preventive Measures and Maintenance Tips

Maintaining a healthy exhaust fluid system is crucial for sustaining vehicle performance and adhering to emission standards. To avoid common exhaust fluid system faults, we’ve compiled a series of preventive measures and maintenance tips.

Regularly Check DEF Levels

Monitoring Diesel Exhaust Fluid (DEF) levels forms the cornerstone of preventative maintenance. We recommend checking DEF levels at regular service intervals and before embarking on long trips. Vehicles equipped with DEF level gauges make monitoring straightforward, while those without could require manual inspection.

Ensure DEF Quality

Using high-quality DEF can’t be overstated. Only purchase DEF from reputable suppliers and verify that it meets the International Organization for Standardization (ISO) 22241 standard. Storing DEF properly also retains its quality, meaning it should be kept in a cool, dry place, away from direct sunlight.

Inspect System Components

Regular inspections of the DEF injector, SCR catalyst, and related sensors are essential. Look for signs of wear, damage, or blockages that could impair system function. Catching and addressing these issues early prevents more significant problems down the line.

Update Software Regularly

Automobile manufacturers occasionally release software updates for the Engine Control Unit (ECU) that can enhance system performance and resolve existing glitches. Keeping the software updated ensures that the exhaust fluid system operates efficiently and remains compliant with emission regulations.

Seek Professional Help

When in doubt, consulting with a professional technician offers the best course of action. Professionals can provide comprehensive system diagnostics, identify subtle issues that might be overlooked, and suggest the most effective solutions. A regular check-up by a technician familiar with exhaust fluid systems can also preempt potential faults.

Adhering to these preventive measures and maintenance tips, we can minimize the risk of exhaust fluid system faults, ensuring our vehicles run smoothly, comply with emission standards, and contribute to environmental protection.

Conclusion

Tackling exhaust fluid system faults head-on is crucial for keeping our vehicles running smoothly and environmentally friendly. We’ve seen how simple steps like monitoring DEF levels and ensuring component integrity can make a big difference. Let’s not wait for warning lights or decreased performance to take action. Regular maintenance and a proactive approach will save us time and money while protecting the environment. Together we can ensure our vehicles meet emission standards and perform at their best. So let’s stay vigilant and keep our rides in top shape!

Related Posts:

- Exhaust Fluid System Fault: Causes, Symptoms, and Solutions

- Ford F150 Transmission Identification Codes: A Comprehensive Guide

- Ford Outside Temperature Sensor Reset: A Quick Guide

- Full Accessory Power Active Meaning: Understanding Your Vehicle’s Electrical System

- How to Bypass Ford Speed Limiter: Tips and Tricks

- What Year Ford Fusion Parts are Interchangeable: A Quick Guide