Navigating the world of semi trucks can be as complex as it is fascinating, especially when it comes to understanding the intricacies of tire positioning. It’s not just about ensuring the tires are properly inflated; it’s about knowing exactly where each tire fits into the grand scheme of things for optimal performance and safety. That’s where a semi truck tire position diagram comes into play, offering a roadmap to the proper placement of each tire on these road giants.

We’ve all seen these behemoths of the road, hauling goods across countries, powering through highways and byways. Yet, the science behind their operation, particularly their tire setup, remains a mystery to many. By diving into the details of a tire position diagram, we’re about to shed some light on this critical aspect, making it easier for drivers, mechanics, and truck enthusiasts to ensure these vehicles are running as smoothly and safely as possible.

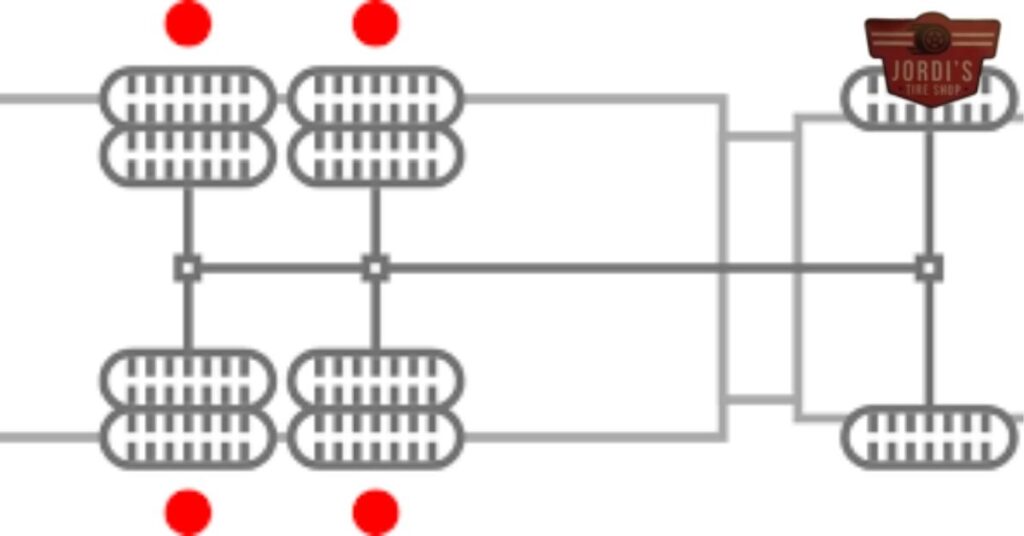

Understanding the Semi Truck Tire Position Diagram

Diving into the semi truck tire position diagram provides a clearer picture of how each tire contributes to the overall performance and safety of the vehicle. This visual representation breaks down the complex layout into an easily understandable format for drivers, mechanics, and truck enthusiasts alike. Let’s explore the key components and what they mean for semi truck operations.

Front Axle Tires

Located at the very front of the semi truck, the tires on the front axle, often referred to as the steer tires, play a pivotal role in steering and stability. These tires bear a significant portion of the truck’s weight, especially when the vehicle is unloaded, making their condition and placement critical.

Drive Axle Tires

Situated in the middle section of the truck, the drive axle tires provide traction, allowing the truck to propel forward or backward. These are typically dual tires on each side, crucial for supporting the heavy load the semi truck carries and transmitting power from the engine to the ground.

Trailer Axle Tires

The trailer axle tires, found at the rear of the trailer, support the cargo’s weight and play a vital role in braking and stability, especially when navigating through corners or during high-speed travel. Like the drive axles, these also usually consist of dual tires on each side to evenly distribute the weight of the load.

Understanding the layout and specific function of each tire position through the semi truck tire position diagram ensures that the right tires are used in the appropriate locations, enhancing the truck’s overall operation. Regular maintenance and checks are essential in these positions to prevent wear and tear, ensuring a safer driving experience.

Types of Tires for Different Positions

In our exploration of semi truck tire positioning, it’s crucial to understand that not all tires are created equal. Depending on their position on the truck, they fulfill different roles, and thus, manufacturers design them with distinct features to meet these specific needs.

- Steer Tires: Located at the front axle, steer tires play a pivotal role in guiding the semi truck on the road. They’re designed for optimal response to steering and stability. To enhance handling, steer tires feature a ribbed tread pattern that maximizes contact with the road surface, providing a smooth and controlled ride. It’s essential for these tires to offer excellent wet grip and durability against constant turns and maneuvers.

- Drive Tires: Fitted on the drive axle, these tires are the powerhouse behind a semi truck’s forward motion. They boast deeper tread patterns with aggressive blocks or lugs to ensure strong traction on various surfaces, whether dry, wet, or snow-covered. The design focuses on providing the necessary propulsion and maintaining grip during acceleration and uphill climbs. Drive tires are also engineered for resistance against wear and tear, given their exposure to constant torque and force.

- Trailer Tires: Supporting the cargo’s weight and assisting in braking, trailer tires are found on the trailer axle. These tires are designed for durability and stability under heavy loads. They usually have a thicker sidewall to resist punctures and abrasions, in addition to a tread pattern that prioritizes even wear and fuel efficiency. Trailer tires must also provide dependable performance in a range of weather conditions, ensuring safety and reliability in long-haul operations.

Understanding the distinct functionalities and designs of tires based on their positions is crucial for maintaining the performance and safety of semi trucks. Each tire type contributes uniquely to the vehicle’s overall operation, emphasizing the importance of selecting the right tire for each position.

Maintaining Tires Based on Position

After selecting the right tire for each position on a semi truck, maintaining these tires becomes paramount to ensure their longevity and the vehicle’s optimal performance. Recognizing the distinct roles that steer, drive, and trailer tires play, we adjust our maintenance strategies accordingly.

Steer Tires

Steer tires, pivotal for steering and stability, demand regular inspection for wear and tear. We prioritize checking for uneven wear patterns, often a sign of misalignment or pressure issues. Maintaining proper inflation is crucial, as it affects handling and fuel efficiency. Rotating steer tires can also extend their lifespan by ensuring even wear.

Drive Tires

Drive tires, responsible for traction and propulsion, require attentiveness to tread depth and condition. We ensure these tires have adequate tread for the drive conditions they’ll face, whether it’s dry highways or snowy paths. Balancing and aligning drive tires contribute to minimizing irregular wear and improving fuel economy. Similar to steer tires, keeping drive tires properly inflated is essential for performance and tire life.

Trailer Tires

Trailer tires, tasked with supporting heavy loads and aiding in braking, undergo checks for punctures or damage that could compromise their durability. We monitor their air pressure closely, as incorrect pressure can lead to overheating and increased wear. Regular inspection for cuts, bulges, or other signs of distress is also part of our routine to prevent blowouts. Additionally, rotating trailer tires helps in distributing the wear evenly, promoting longer service life.

Through vigilant maintenance tailored to the unique demands of steer, drive, and trailer tires, we safeguard not only the tires themselves but also the overall safety and efficiency of the semi truck. Adhering to a structured maintenance schedule ensures each tire performs its role as expected, contributing to a smoother and safer journey.

Optimizing Performance Through Tire Positioning

Building on the foundation of selecting the right tires and adhering to specific maintenance practices, we delve deeper into optimizing performance through strategic tire positioning. Understanding the role each tire plays in ensuring safety and efficiency paves the way for enhanced semi-truck operations.

Firstly, steer tires, positioned at the front of the semi-truck, dictate the vehicle’s direction. Maintaining these with proper inflation and regular checks for wear is non-negotiable. Ensuring steer tires are of high quality and in top condition facilitates easier steering and better control, crucial for maneuvering through traffic and adverse weather conditions.

Secondly, drive tires, located on the semi-truck’s drive axles, are paramount for traction. These tires convert the engine’s power into movement. For optimal performance and fuel efficiency, rotating drive tires regularly aids in even wear distribution. This practice, combined with monitoring tread depth and alignment, maximizes the grip and stability of the vehicle, especially under load or in wet conditions.

Lastly, trailer tires support the heavy loads and absorb road shocks. Positioned on the trailer, these tires must withstand varying weights and continuous use over long distances. Regularly checking for damage and maintaining correct air pressure in trailer tires ensures their durability and prevents premature failure. Keeping them in good shape not only contributes to the semi-truck’s overall performance but also safeguards the cargo being transported.

Optimizing tire positioning and maintenance based on the specific role of each tire maximizes the performance, safety, and efficiency of semi-trucks. It’s a critical aspect that, if managed correctly, can lead to significant savings in fuel and maintenance costs while ensuring the safety of the cargo and driver. Applying these principles, we aid in achieving a smoother, safer journey.

Conclusion

We’ve explored the critical roles that tire positions play in the safety and efficiency of semi trucks. By understanding the unique needs of steer, drive, and trailer tires, we can make informed decisions that enhance performance and extend tire life. Remember, it’s not just about choosing the right tires but also about maintaining them according to their specific roles. Let’s put this knowledge into practice and ensure our trucks are running smoothly and safely on the road. Here’s to fewer breakdowns and more efficient journeys ahead!

Related Posts:

- 2021 Mitsubishi Outlander Sport Towing Capacity: A Friendly Guide

- A Guide to the “A in a Circle” Symbol on Your Car

- Big O Tire Installation Fee: What You Need to Know

- Biggest Tires for 18 Inch Rims: A Comprehensive Guide

- Mechanic for European Cars: Expertise and Affordable Services

- Radio Keeps Changing Stations By Itself: How to Fix It

- Semi Truck Tire Position Diagram: A Helpful Guide for Drivers

- Mitsubishi Staten Island: Your Ultimate Guide to Finding the Best Dealership

- Ford 3.3 V6 Problems: Common Issues and Solutions

- 5.3 Lifter Replacement Made Easy Without Removing Head