We’ve all seen them – those weathered vehicles that tell stories of countless miles and forgotten adventures. Rust isn’t just a cosmetic issue; it’s a silent destroyer that can transform your beloved car into a safety hazard and financial burden. Whether you’re dealing with surface spots or deep corrosion, understanding rust’s impact on your vehicle is crucial for every car owner.

The sight of rust bubbling through paint or eating away at metal panels can feel overwhelming, but it doesn’t have to spell disaster. With the right knowledge and approach, many rust issues can be addressed before they become catastrophic problems. We’ll explore everything from identifying early warning signs to understanding when restoration becomes worthwhile.

From classic car enthusiasts preserving automotive history to everyday drivers protecting their investment, rust prevention and treatment strategies can save thousands of dollars and extend your vehicle’s lifespan significantly.

Why Rusty Cars Develop Over Time

Understanding the factors behind rust formation helps us protect our vehicles from costly deterioration. Multiple environmental and maintenance issues work together to accelerate this destructive process.

Environmental Factors That Accelerate Rust

Salt exposure creates the most aggressive rust conditions we encounter on our roads. Winter road salt, coastal air, and even salted parking lots introduce chloride ions that speed up the oxidation process by up to 5 times compared to normal conditions.

Moisture becomes trapped in hidden areas like door frames, wheel wells, and undercarriage components where air circulation is poor. These pockets of humidity create perfect breeding grounds for rust formation, especially when temperatures fluctuate between freezing and thawing.

Temperature changes cause metal expansion and contraction that creates microscopic cracks in protective coatings. Paint chips, scratches, and worn areas allow moisture to reach bare metal surfaces where rust begins almost immediately.

Industrial pollution and acid rain introduce corrosive chemicals that break down protective layers faster than normal weathering. Urban areas with heavy traffic or nearby factories expose vehicles to sulfur compounds and other airborne contaminants.

Humidity levels above 50% create ideal conditions for rust development, particularly in garages or storage areas without proper ventilation. Coastal regions naturally maintain higher humidity levels that accelerate the corrosion process year round.

Poor Maintenance Practices That Lead to Corrosion

Neglecting regular washing allows salt and debris accumulation in critical areas like the undercarriage, wheel wells, and door jambs. We recommend washing these areas at least monthly during winter months and after driving on salted roads.

Ignoring small paint chips and scratches gives rust immediate access to bare metal surfaces. Touch up paint costs under $20 per bottle, while rust repair can cost hundreds or thousands of dollars once corrosion spreads.

Skipping routine inspections means missing early warning signs like bubbling paint, surface discoloration, or small rust spots that are easily treatable. Monthly visual checks of common rust areas take less than 10 minutes but prevent major problems.

Storing wet or dirty vehicles in enclosed spaces traps moisture against metal surfaces for extended periods. Always dry vehicles thoroughly before garage storage, especially after driving through puddles or washing.

Using improper cleaning products can damage protective wax coatings and paint finishes that prevent rust formation. Harsh detergents, salt based ice melters, and abrasive cleaners remove the barriers that keep moisture away from metal components.

How to Identify Early Signs of Rust on Your Vehicle

Recognizing rust before it spreads can save thousands in repair costs and prevent serious safety issues. We’ll guide you through the key indicators that signal your vehicle needs immediate attention.

Surface Rust vs. Penetrating Rust

Surface rust appears as small orange or brown spots on your car’s exterior and represents the earliest stage of corrosion. These spots typically measure less than a quarter inch and feel rough to the touch when you run your finger across them. Surface rust only affects the top layer of metal and can be easily treated with sandpaper and touch up paint if caught early.

Penetrating rust creates visible holes or deep pitting in the metal and indicates serious structural damage. This advanced corrosion eats through multiple layers of steel and often requires professional panel replacement or welding repairs. Penetrating rust feels soft or flaky when touched and may cause sections of metal to crumble away completely.

Bubble formation under paint signals rust developing beneath the surface before it becomes visible. These bubbles start small but expand rapidly as moisture continues to reach the metal underneath. Paint that looks raised or distorted over areas larger than a dime typically indicates penetrating rust beginning to form.

Common Areas Where Rust Typically Forms

Wheel wells collect road salt, dirt, and moisture more than any other vehicle area, making them prime locations for rust development. Check behind the plastic wheel well liners where debris often accumulates and creates persistent wet conditions. Rust in wheel wells can spread to suspension components and compromise your vehicle’s handling safety.

Door frames trap water in their lower sections and develop rust around hinges, handles, and weather stripping. Examine the bottom edges of doors where drainage holes might become clogged with leaves or debris. Door rust can prevent proper sealing and lead to interior water damage if left untreated.

Rocker panels run along the bottom of your car between the front and rear wheels and face constant exposure to road spray. These panels often show rust first because they sit close to the ground and collect salt water mixtures. Rocker panel rust can spread upward into the car’s structural framework and require expensive bodywork.

Trunk and hood edges develop rust where water pools after washing or rain exposure. Look for discoloration along the rubber seals and metal contact points where moisture tends to remain trapped. Trunk rust often starts near the license plate area where mounting holes allow water penetration.

Frame rails underneath your vehicle corrode from road salt and moisture without regular inspection and cleaning. Use a flashlight to check for orange or brown staining on the metal framework that supports your car’s structure. Frame rust represents the most serious corrosion threat and can make your vehicle unsafe to drive.

What Causes Rust to Spread So Quickly on Cars

Rust doesn’t just appear overnight – it spreads through your car’s metal surfaces at an alarming rate once the oxidation process begins. Understanding the exact factors that accelerate this deterioration helps us protect our vehicles before minor surface rust becomes a major structural problem.

The Role of Salt and Road Chemicals

Road salt creates one of the most aggressive environments for automotive metal corrosion. Winter deicing chemicals like sodium chloride and calcium chloride attract moisture from the air, forming a corrosive brine that clings to metal surfaces long after the snow melts. This salt solution acts as a catalyst, speeding up the electrochemical reaction that turns iron into rust at rates up to 10 times faster than normal oxidation.

Coastal vehicles face similar challenges from ocean salt spray, which can travel inland for miles and settle on car surfaces. Salt doesn’t just cause rust – it helps existing rust spread by creating pathways for moisture to penetrate deeper into the metal structure. Even small amounts of salt residue can continue the corrosion process for months if not properly removed.

Other road chemicals compound the problem significantly. Magnesium chloride and potassium acetate, commonly used in modern deicing applications, prove even more corrosive than traditional rock salt. These chemicals remain active at lower temperatures and create persistent moisture films that keep metal surfaces in constant contact with corrosive elements.

How Moisture and Humidity Affect Metal Deterioration

Moisture serves as the primary catalyst for rust formation, creating the perfect environment for iron oxidation to occur. Water molecules provide the medium through which oxygen and metal ions react, transforming solid steel into crumbling iron oxide. High humidity levels above 50% significantly accelerate this process, particularly in enclosed spaces like garages where air circulation remains limited.

Temperature fluctuations make moisture problems even worse by causing condensation to form in hidden vehicle crevices. Warm days followed by cool nights create cycles of moisture accumulation that keep metal surfaces constantly damp. These wet and dry cycles prove more damaging than consistent moisture because they allow rust to penetrate deeper with each temperature change.

Trapped moisture becomes especially problematic in areas where drainage fails to function properly. Door seals, window channels, and floor pan drain holes often collect water that sits against bare metal for extended periods. Standing water in these locations creates perfect conditions for rust colonies to establish and spread throughout connected metal structures.

Where Rust Most Commonly Appears on Vehicles

Understanding where rust typically forms helps us catch problems before they become expensive repairs. We’ll examine the most vulnerable areas where corrosion strikes first and spreads fastest.

Wheel Wells and Fender Areas

Wheel wells face constant bombardment from road debris, salt, and moisture kicked up by tires. Water and mud collect in these enclosed spaces, creating perfect conditions for rust to develop. Fender areas trap moisture behind plastic linings where we can’t easily see damage forming.

Stone chips and scratches in wheel well paint expose bare metal to the elements. Salt accumulation during winter months accelerates corrosion in these hidden spaces. Drainage holes often become clogged with debris, allowing water to pool and creating rust breeding grounds.

We find rust spreading from inner fender panels to outer body sections when left unchecked. Regular cleaning of wheel wells removes corrosive materials before they cause permanent damage. Inspecting these areas requires removing wheels or using a flashlight to peer into dark corners.

Door Frames and Window Seals

Door frames collect moisture from rain and washing, especially around weatherstrip channels. Water seeps into gaps between door panels and frames, remaining trapped for extended periods. Window seal areas develop rust when drainage systems become blocked or damaged.

Paint damage around door handles and locks creates entry points for corrosion. Moisture migrates through door panel seams, attacking metal from the inside out. We often discover extensive rust damage hidden behind door panels during repair work.

Lower door sections near ground level face the most exposure to salt spray and road chemicals. Rust typically begins at the bottom of door frames and works upward along seam lines. Checking door seals regularly prevents water intrusion that leads to hidden corrosion damage.

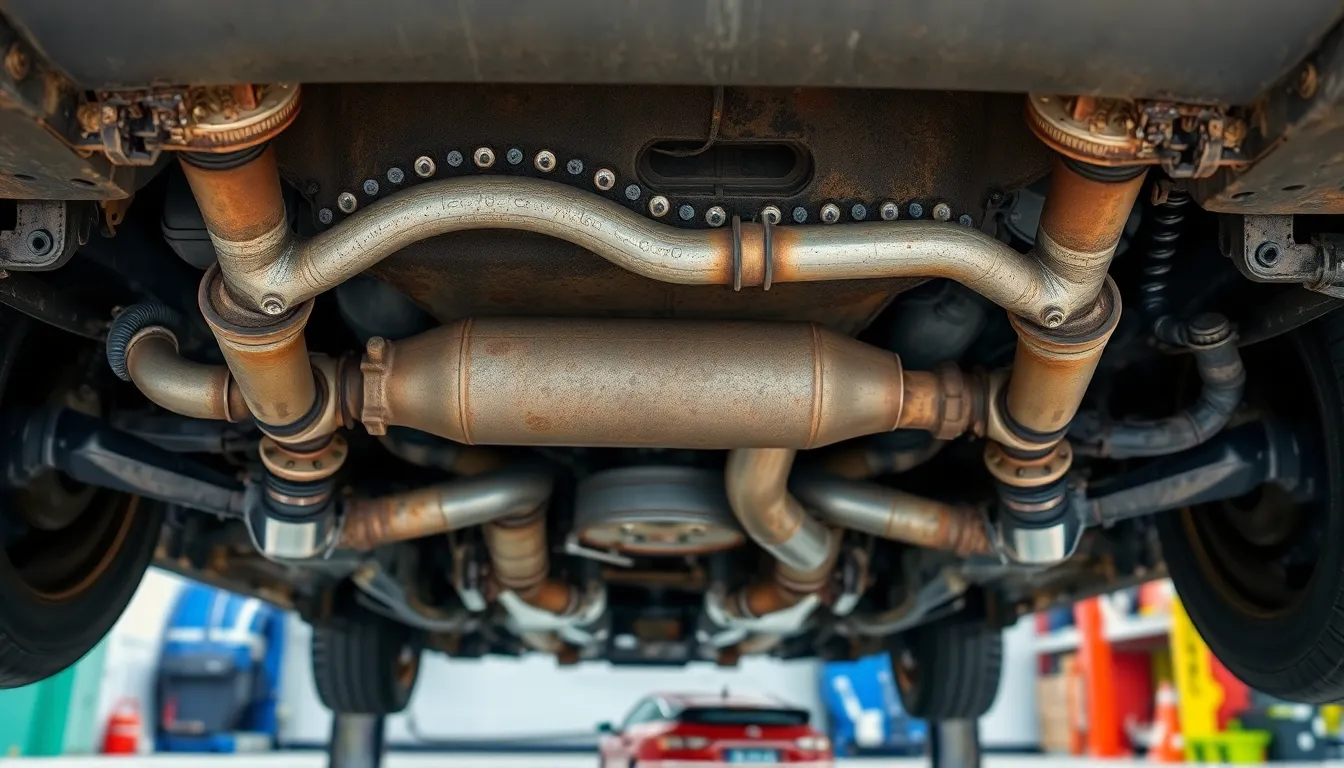

Undercarriage and Exhaust Systems

Undercarriage components experience direct exposure to road salt, chemicals, and moisture from below. Exhaust systems face extreme temperature changes that accelerate rust formation through thermal cycling. Frame rails and cross members develop corrosion where protective coatings wear away.

Exhaust pipes and mufflers rust from both inside and outside due to condensation and road exposure. Heat shields trap moisture and debris against exhaust components, creating localized rust spots. We see catastrophic failures when exhaust hangers rust through completely.

Suspension mounting points become compromised when rust attacks attachment areas on the frame. Oil pan and transmission housing areas collect road grime that holds moisture against metal surfaces. Regular undercarriage washing removes corrosive materials but requires thorough drying to prevent trapped moisture problems.

When to Repair vs. When to Replace Rusty Cars

Making smart decisions about rust repair versus replacement can save thousands of dollars and ensure your safety on the road. We’ll examine the key factors that determine whether your rusty car deserves restoration or replacement.

Cost-Effective Repair Answers for Minor Rust

Surface rust repair offers the most affordable solution for minor corrosion issues. We can address small rust spots with DIY kits costing $20 to $50, which include sandpaper, primer, and touch-up paint. Professional surface rust treatment typically ranges from $100 to $500 per panel, depending on the affected area size.

Spot welding repairs work well for holes smaller than a quarter. We recommend this approach when rust damage affects less than 10% of a panel’s surface area. Professional welding services cost between $200 to $800 per repair, significantly less than full panel replacement.

Rust converter applications provide excellent value for treating moderate corrosion on frames and undercarriage components. We’ve seen costs range from $15 to $100 for converter products that stop rust progression and create a protective barrier. This method works best on rust that hasn’t completely penetrated the metal.

Panel patching becomes worthwhile when rust damage covers 10% to 30% of a single panel. We find repair costs typically run $300 to $1,200 per panel, compared to $800 to $2,500 for complete panel replacement. This approach maintains structural integrity while controlling expenses.

Signs That Indicate Total Vehicle Replacement

Extensive frame damage signals the end of cost-effective repairs. We consider replacement necessary when rust affects more than 40% of the vehicle’s frame rails or main structural components. Frame replacement costs often exceed 80% of the car’s market value.

Multiple system failures from rust corrosion indicate replacement time. We’ve observed that vehicles requiring simultaneous repairs to brake lines, fuel lines, exhaust systems, and suspension components rarely justify the expense. Total repair costs in these cases frequently surpass $8,000 to $15,000.

Safety-critical rust penetration demands immediate replacement consideration. We recommend replacement when rust creates holes in seat mounting points, steering components, or suspension attachment areas. These failures pose serious accident risks that no repair can adequately address.

Economic replacement thresholds become clear when repair estimates exceed 60% to 70% of the vehicle’s current market value. We calculate this by comparing total restoration costs against similar vehicles’ purchase prices in good condition. Cars with values under $5,000 rarely justify repairs exceeding $3,000.

Recurring rust patterns suggest systemic corrosion problems that’ll continue spreading. We’ve noticed that vehicles showing rust in five or more major areas within two years typically develop ongoing issues. These patterns indicate compromised metal integrity that makes future repairs inevitable and expensive.

Which Tools and Products Remove Rust Effectively

Once you’ve identified rust on your vehicle, selecting the right removal method determines whether you’ll achieve lasting results or face recurring problems.

Chemical Rust Removers and Converters

Chemical rust removers offer the most thorough solution for treating corrosion without damaging surrounding metal. We recommend phosphoric acid based products like Naval Jelly and Loctite Naval Jelly Rust Dissolver, which dissolve rust completely while neutralizing the oxidation process. These products work by converting iron oxide back into stable metal compounds.

Rust converters transform existing rust into a protective coating rather than removing it entirely. Corroseal Water Based Rust Converter and SEM Metal Prep create a black protective layer that prevents further corrosion. Apply these products directly to rusty surfaces without extensive prep work.

Penetrating oils like PB Blaster and Liquid Wrench break down rust bonds in hard to reach areas. Spray these answers into wheel wells, door frames, and undercarriage components where mechanical removal isn’t practical. Allow 24 to 48 hours for maximum penetration before wiping away loosened rust particles.

Electrolytic rust removal uses electrical current and a sodium carbonate solution to strip rust from metal parts. This method works exceptionally well for small components like bolts, brackets, and hardware pieces. Set up requires a battery charger, sacrificial steel electrode, and plastic container, but results are completely rust free metal surfaces.

Mechanical Removal Methods and Equipment

Mechanical removal methods give you immediate visual results and work best on accessible rust areas. We use angle grinders with wire brush attachments for heavy rust removal on flat surfaces like rocker panels and door skins. These tools remove rust quickly but require steady hands to avoid gouging the underlying metal.

Wire brushes in various sizes handle detail work around curves and tight spaces. Hand wire brushes work well for surface rust, while rotary wire brushes attached to drills tackle moderate corrosion. Choose brass brushes for softer metals and steel brushes for heavy duty applications.

Sandpaper and sanding blocks provide precise control over rust removal depth. Start with 80 grit paper for heavy rust, progress to 220 grit for smoothing, and finish with 400 grit for paint preparation. Wet sanding prevents dust buildup and reduces heat damage to surrounding paint.

Sandblasting equipment offers professional level rust removal for complete restoration projects. Media blasters use sand, glass beads, or walnut shells to strip rust down to bare metal. This method requires proper ventilation and safety equipment but delivers the most thorough results possible.

Oscillating tools with carbide scrapers excel at removing rust from curved surfaces and confined areas. These tools vibrate rather than rotate, giving you better control in delicate situations like around window seals and trim pieces.

Who Should Handle Rust Repair on Your Car

Choosing the right approach for rust repair depends on the severity of corrosion and your skill level. We’ll explore when you can tackle rust removal yourself and when professional intervention becomes essential.

DIY Rust Removal for Beginners

Surface rust removal represents the most manageable project for weekend mechanics and car enthusiasts. We recommend starting with small rust spots on non-structural areas like door panels or hood surfaces where mistakes won’t compromise vehicle safety.

Essential tools for beginner rust repair include steel wool, sandpaper ranging from 80 to 400 grit, rust converter products, and basic safety equipment. You’ll need protective eyewear, gloves, and a dust mask to prevent inhalation of rust particles during the removal process.

Step-by-step approach works best for DIY rust removal projects. Start by cleaning the affected area thoroughly with soap and water, then sand away loose rust using coarse-grit sandpaper. Apply rust converter to neutralize remaining oxidation, prime the bare metal, and finish with matching paint to prevent future corrosion.

Time investment typically ranges from 2 to 6 hours for small rust spots, depending on the size and location of the damage. Most beginners can successfully complete minor rust repairs on weekends using common garage tools and readily available products from auto parts stores.

Cost savings make DIY rust removal attractive for budget-conscious vehicle owners. Basic rust repair supplies cost between $30 and $80, compared to professional services that often charge $200 to $500 for similar work on small areas.

When Professional Auto Body Services Are Necessary

Structural rust damage requires professional expertise because it affects vehicle safety and frame integrity. We strongly recommend professional services when rust appears on frame rails, suspension mounting points, or other load-bearing components that support vehicle operation.

Advanced welding requirements make professional intervention necessary for holes larger than a quarter or areas where metal replacement becomes essential. Auto body technicians possess specialized welding equipment and metal fabrication skills that ensure proper structural repairs and long-term durability.

Paint matching expertise provided by professional shops ensures seamless color integration that maintains your vehicle’s appearance and resale value. Professional painters use computerized color matching systems and spray booth facilities that deliver factory-quality finishes impossible to achieve in home garages.

Insurance coverage often applies to extensive rust repairs, particularly when corrosion affects safety-critical components or results from collision damage. Professional shops handle insurance documentation, provide detailed estimates, and guarantee their work with warranties that protect your investment.

Multiple system involvement signals the need for professional assessment when rust affects electrical components, brake lines, fuel systems, or exhaust components simultaneously. These complex repairs require diagnostic equipment and specialized knowledge to ensure all affected systems function properly after rust remediation.

Time constraints make professional services practical when rust repair timelines conflict with daily transportation needs. Professional shops complete comprehensive rust repairs in 3 to 10 business days, compared to weekend DIY projects that might extend over several months.

How Much Rust Repair Typically Costs Car Owners

Understanding rust repair costs helps us make informed decisions about maintaining our vehicles and avoiding unexpected expenses. We’ve analyzed current market rates and repair scenarios to provide accurate cost estimates for different rust situations.

Budget-Friendly Prevention and Maintenance

Preventive rust treatments offer the most cost-effective approach to protecting our vehicles from corrosion damage. We can apply professional undercoating services for $150 to $400, which creates a protective barrier against salt and moisture for 2-3 years. Surface rust removal using DIY kits costs between $25 to $75 per affected area, making early intervention highly affordable.

Regular maintenance services keep rust repair costs minimal when we address issues promptly. Professional rust inspection services typically charge $75 to $150, helping us identify problem areas before they become expensive repairs. Touch-up paint applications for small scratches cost $50 to $120 per panel, preventing moisture from reaching bare metal surfaces.

Monthly washing and waxing represents our most economical rust prevention strategy at $30 to $60 per session. We save thousands in future repair costs by removing salt deposits and applying protective coatings regularly. Cavity wax treatments for door frames and hidden areas cost $100 to $200 annually but provide exceptional value for money.

Expensive Restoration Project Estimates

Major structural rust repairs require important investment and professional expertise to restore vehicle safety. We face costs ranging from $2,500 to $8,000 when dealing with frame rail corrosion that affects the vehicle’s structural integrity. Complete rocker panel replacement typically costs $1,200 to $3,500 per side, depending on vehicle complexity and labor rates.

Extensive body panel restoration becomes necessary when rust has penetrated multiple areas of our vehicle. Floor pan replacement projects range from $1,800 to $4,200, while quarter panel restoration costs $2,000 to $5,500 per panel. We often discover additional rust damage during restoration, increasing project costs by 25% to 40% beyond initial estimates.

Complete vehicle restoration for classic or valuable cars can exceed $15,000 to $40,000 when rust has affected multiple systems. Engine bay restoration adds $3,000 to $7,500 to project costs, while suspension component replacement ranges from $2,200 to $5,800. We must consider that labor costs represent 60% to 70% of total restoration expenses in most professional shops.

| Repair Type | Cost Range | Timeline |

|---|---|---|

| Surface rust treatment | $25-$150 | 1-2 hours |

| Small hole repair | $200-$600 | 4-8 hours |

| Panel replacement | $800-$2,500 | 1-3 days |

| Frame repair | $2,500-$8,000 | 1-2 weeks |

| Full restoration | $15,000-$40,000 | 3-6 months |

Ways to Prevent Future Rust Formation

Preventing rust formation requires consistent care and proactive measures that protect your vehicle from the elements. These preventive strategies cost far less than major repairs and can extend your car’s lifespan significantly.

Regular Washing and Waxing Schedules

Weekly washing removes salt and corrosive materials before they can penetrate your vehicle’s protective layers. Road salt from winter driving creates the most aggressive environment for rust formation, making frequent washing essential during these months. We recommend washing your car at least once per week during winter conditions and every two weeks during mild weather.

Thorough undercarriage cleaning eliminates hidden threats that standard washing often misses. Trapped debris and salt accumulation in wheel wells, suspension components, and frame rails create perfect conditions for rust to develop. Professional car washes with undercarriage spray options provide the most effective cleaning for these hard to reach areas.

Quality wax applications create a protective barrier that repels moisture and prevents direct metal contact with corrosive elements. Apply automotive wax every three to four months to maintain optimal protection. Premium carnauba wax products offer superior durability compared to synthetic alternatives, lasting longer and providing better water resistance.

Immediate attention to minor damage prevents major problems from developing over time. Small chips and scratches expose bare metal to moisture and oxygen, creating entry points for rust formation. Touch up paint should be applied within 48 hours of discovering damage to maintain your vehicle’s protective coating integrity.

Protective Coatings and Undercarriage Treatments

Professional undercoating services provide long lasting protection against moisture and corrosive materials that attack your vehicle’s undercarriage. Rubberized undercoating products create a flexible barrier that moves with your car’s metal components without cracking or peeling. Most professional applications cost between $300 to $800 and last five to seven years with proper maintenance.

Rust inhibitor sprays penetrate existing surface oxidation while preventing future corrosion from spreading to healthy metal areas. Oil based rust inhibitors like Corrosion X and Fluid Film provide superior penetration compared to wax based products. These treatments should be reapplied annually for maximum effectiveness, especially in high salt environments.

Ceramic coating applications offer premium protection for paint surfaces and exposed metal components throughout your vehicle. Professional ceramic coatings last three to five years and provide superior resistance to chemical damage, UV exposure, and environmental contaminants. The initial investment of $1,000 to $3,000 pays for itself through reduced maintenance costs and preserved vehicle value.

Cavity wax injection protects hidden areas where moisture commonly accumulates and causes severe structural damage over time. Professional technicians inject specialized wax compounds into door frames, rocker panels, and other enclosed spaces through small access holes. This treatment prevents moisture buildup in areas that regular washing and waxing cannot reach, making it essential for long term rust prevention.

Worth Considering: Buying Rusty Cars as Project Vehicles

Rusty cars often present unique opportunities for automotive enthusiasts seeking restoration projects. We’ll explore how these vehicles can become rewarding investments when approached with proper planning and realistic expectations.

Evaluating Restoration Potential and Value

Structural integrity assessment forms the foundation of any successful rusty car evaluation. We examine the frame rails first since they’re critical load-bearing components that determine whether a restoration remains feasible. Frame damage requiring professional welding can push costs beyond $15,000, making many projects financially impractical.

Body panel conditions reveal the scope of metalwork needed for restoration success. Door frames, rocker panels, and fender areas typically show rust first, with replacement panels ranging from $200 to $800 each. We calculate that surface rust covering less than 30% of visible areas often indicates manageable restoration work.

Engine bay rust patterns help us determine mechanical system viability and overall project costs. Radiator support structures and firewall areas showing penetrating rust may require extensive fabrication work. We find that vehicles with clean engine compartments even though exterior rust often hide better restoration potential.

Market value research guides our restoration budget decisions and profit expectations. Classic muscle cars from the 1960s and 1970s maintain strong restoration values, with finished projects often worth $25,000 to $75,000. We compare similar restored vehicles to establish realistic target values before committing to expensive restoration work.

Documentation availability affects both restoration accuracy and final vehicle value significantly. Original build sheets, service records, and parts catalogs can increase a restored car’s worth by 15% to 25%. We prioritize vehicles with matching numbers and complete documentation when evaluating project potential.

Hidden Costs in Rusty Car Restoration Projects

Parts availability challenges create unexpected expenses that can double initial restoration budgets. Reproduction panels for popular models like Ford Mustangs cost $300 to $600 each, while rare vehicle parts often require custom fabrication at $100 to $200 per hour. We budget an additional 40% beyond visible repair needs to account for these hidden requirements.

Professional welding services become necessary when rust damage exceeds DIY capabilities and safety limits. Structural repairs involving frame rails, suspension mounting points, and safety cage work require certified welders charging $75 to $150 per hour. We estimate that extensive welding projects consume 60 to 100 hours of professional labor.

Paint and bodywork preparation costs escalate quickly when rust damage appears more extensive than initially visible. Complete paint removal through media blasting ranges from $1,500 to $3,500 depending on vehicle size and rust severity. We discover that thorough preparation work often reveals additional rust requiring metalwork before painting can begin.

Mechanical system restoration becomes necessary when rust affects critical components beyond cosmetic areas. Brake lines, fuel systems, and exhaust components corroded by rust require complete replacement for safety and reliability. We factor in $2,000 to $5,000 for mechanical system restoration in moderate rust damage scenarios.

Storage and workspace expenses accumulate during extended restoration periods that stretch beyond initial timelines. Heated garage rental costs $200 to $500 monthly in most areas, while professional restoration shops charge storage fees when projects extend beyond agreed schedules. We recommend budgeting for 18 to 24 months of storage costs since most restoration projects take longer than anticipated.

Specialty tool requirements increase project expenses when standard equipment proves insufficient for rust repair work. Plasma cutters, welding equipment, and metal forming tools cost $1,500 to $5,000 to purchase or $50 to $100 daily to rent. We find that tool costs alone can represent 10% to 15% of total project budgets for comprehensive rust restoration work.

Conclusion

We’ve explored the complete spectrum of rust management from early detection to restoration decisions. Understanding these fundamentals empowers us to protect our vehicles and make informed choices when rust appears.

Whether we’re dealing with surface spots or considering a full restoration project the key lies in acting promptly and choosing the right approach for our situation. Regular inspections and proper maintenance remain our best defense against costly rust damage.

Remember that every rusty car tells a story and with the right knowledge we can determine whether that story ends in restoration success or smart replacement. The tools and techniques we’ve discussed provide a solid foundation for tackling rust challenges head-on.

By staying vigilant and applying these strategies we can extend our vehicles’ lifespans and avoid the financial burden of advanced corrosion damage.

Frequently Asked Questions

What are the main environmental factors that cause rust in vehicles?

The primary environmental factors causing rust include salt exposure from winter roads and coastal air, trapped moisture in hidden areas, temperature fluctuations, industrial pollution, and high humidity levels. Road salt and deicing chemicals create particularly corrosive environments that accelerate rust formation significantly.

Where does rust most commonly appear on cars?

Rust typically forms in wheel wells, door frames, rocker panels, trunk and hood edges, and frame rails. These areas are vulnerable due to moisture accumulation, poor drainage, and constant exposure to road debris, salt, and environmental elements.

What’s the difference between surface rust and penetrating rust?

Surface rust appears as small orange or brown spots on the paint and can be treated easily with DIY methods. Penetrating rust creates visible holes and indicates serious structural damage that requires professional repair or replacement.

How can I prevent rust from developing on my vehicle?

Regular washing, prompt repair of paint damage, routine inspections, proper storage in dry conditions, and using appropriate cleaning products are essential. Avoid storing wet vehicles and pay special attention to areas prone to moisture accumulation.

When should I repair rust versus replace my car?

Repair rust when costs are reasonable and damage is localized. Consider replacement when repair costs exceed 60-70% of your vehicle’s market value, or when there’s extensive frame damage, multiple system failures, or recurring rust patterns.

What are the best tools for rust removal?

Effective rust removal tools include phosphoric acid-based chemical removers, rust converters that transform rust into protective coatings, penetrating oils for hard-to-reach areas, and mechanical methods like angle grinders and sandblasting for accessible rust spots.

Can rusty cars be good project vehicles?

Yes, rusty cars can make excellent project vehicles if you evaluate structural integrity, body panel conditions, and engine bay rust patterns first. Research market values and parts availability to determine restoration feasibility and potential costs.

What hidden costs should I expect when restoring a rusty car?

Hidden costs include parts availability challenges, professional welding services, paint and bodywork preparation, mechanical system restoration, storage and workspace expenses, and specialty tools required for comprehensive rust repair work.