Rally cars represent the ultimate fusion of speed technology and human courage. These purpose-built machines tear through forests at breakneck speeds while handling treacherous terrain that would challenge even the most capable SUVs. We’re talking about vehicles that can launch over crests at 100+ mph then immediately tackle tight hairpin turns on gravel surfaces.

What sets rally cars apart isn’t just their raw power—it’s their incredible engineering. From advanced all-wheel-drive systems to lightning-fast sequential gearboxes these machines are designed to handle whatever Mother Nature throws at them. We’ve seen them conquer everything from snow-covered mountain passes to scorching desert dunes.

Whether you’re a motorsport enthusiast or simply curious about automotive excellence rally cars offer a fascinating glimpse into cutting-edge technology. Let’s explore what makes these incredible machines tick and why they continue to captivate audiences worldwide.

What Are Rally Cars and Why They’re Built Different

Rally cars represent the ultimate fusion of racing technology and rugged durability. These specialized machines undergo extensive modifications to handle the most demanding motorsport conditions on Earth.

Purpose-Built for Extreme Conditions

Rally cars tackle terrain that would destroy ordinary vehicles. We see these machines conquering snow-covered mountain passes in Monte Carlo, handling dusty gravel roads in Finland, and powering through muddy forest trails in Wales. Engineers design every component to withstand impacts from rocks, jumps over crests, and constant vibration from rough surfaces.

Suspension systems receive the most dramatic upgrades. Rally cars feature long-travel suspension with specialized dampers that adjust compression and rebound rates. These systems typically offer 8-10 inches of wheel travel compared to 3-4 inches in standard cars. MacPherson struts or multi-link setups handle the punishment while maintaining wheel contact with uneven terrain.

Protection becomes paramount in rally car construction. Roll cages made from chromoly steel tubing create a safety cell around drivers and co-drivers. These cages must meet FIA specifications with precise tube diameter, wall thickness, and joint requirements. Additional protection includes skid plates underneath the engine and transmission, protecting vital components from rocks and debris.

Key Differences from Regular Road Cars

Weight reduction transforms rally cars into lean racing machines. Manufacturers strip interior components like rear seats, sound deadening, air conditioning, and non-essential electrical systems. Carbon fiber or fiberglass body panels replace steel components where regulations permit. A typical rally car weighs 2,650-3,000 pounds compared to 3,500-4,000 pounds for its road-going counterpart.

Engine modifications deliver explosive power and reliability. Rally engines feature reinforced internals including forged pistons, strengthened connecting rods, and upgraded valve trains. Turbocharging systems provide power across wide RPM ranges with anti-lag systems that maintain boost pressure between gear changes. These engines produce 300-380 horsepower while maintaining durability for 200+ competitive miles.

Transmission systems prioritize quick shifts and durability. Sequential manual transmissions replace standard H-pattern gearboxes, allowing drivers to shift gears using paddle shifters in milliseconds. Limited-slip differentials in both front and rear axles distribute power effectively across surfaces with varying grip levels. All-wheel-drive systems feature adjustable center differentials that drivers can modify during stages.

Specialized tires and wheels handle diverse conditions. Rally cars use different tire compounds for each surface type including soft compound tires for tarmac, intermediate treads for mixed surfaces, and studded tires for ice and snow. Wheel sizes typically measure 15 inches in diameter with reinforced construction to resist impact damage from stones and curbs.

Essential Safety Features That Keep Rally Drivers Alive

Rally cars push engineering limits in extreme conditions, making comprehensive safety systems absolutely critical for driver survival. We’ll explore the three fundamental safety components that protect drivers during high-speed competition.

Roll Cage Construction and Materials

Roll cages form the structural backbone of rally car safety systems, using chromoly steel tubing that’s significantly stronger than standard automotive steel. We see these cages built with precise specifications that include door bars, roof supports, and diagonal bracing to create a protective cocoon around the driver compartment.

Manufacturing standards require exact tube diameter and wall thickness measurements, with most rally cages using 45mm diameter tubing with 2.5mm wall thickness. The welding process demands certified techniques to ensure joints maintain structural integrity under extreme loads.

Integration points connect the cage directly to the car’s chassis at reinforced mounting locations, distributing crash forces throughout the entire structure rather than concentrating them at single points. This design approach helps the cage maintain its shape during rollovers or side impacts that frequently occur in rally competition.

Fire Suppression Systems

Fire suppression systems provide automatic protection against the constant fire risk present in rally cars, which carry large fuel loads and operate in crash-prone environments. We find these systems typically use AFFF (Aqueous Film Forming Foam) or Novec 1230 as suppression agents, both proven effective on fuel fires.

Activation methods include both manual triggers accessible to the driver and automatic heat-sensitive devices that deploy without driver intervention if temperatures exceed safe thresholds. The system’s distribution network routes suppression agent to the engine bay, cockpit, and fuel cell areas through strategically placed nozzles.

Response time becomes critical during fire emergencies, with quality systems deploying suppression agents within 10 seconds of activation. Regular system inspections ensure proper pressure levels and verify that discharge nozzles remain unobstructed throughout the demanding rally environment.

Driver Safety Equipment Requirements

Driver safety equipment creates multiple layers of protection through specialized gear designed specifically for motorsport applications. We see requirements that include FIA-approved helmets rated for rally competition, featuring enhanced impact protection and communication system integration.

Safety harnesses use six-point configurations with 3-inch shoulder straps and 2-inch lap belts, anchoring to reinforced mounting points that distribute crash loads across the strongest areas of the roll cage structure. These harnesses require replacement every five years or after any important impact.

Protective clothing includes fire-resistant suits meeting FIA 8856-2018 standards, constructed from multiple layers of Nomex material that provide thermal protection for at least 12 seconds in direct flame contact. HANS (Head and Neck Support) devices reduce the risk of basilar skull fractures by limiting head movement during frontal impacts, while specialized racing seats with head restraints provide additional spinal protection during competition.

Performance Modifications That Make Rally Cars Fast

Rally cars achieve their incredible speed through precise performance modifications that transform ordinary vehicles into racing machines. We’ll explore the key upgrades that give these cars their competitive edge.

Engine Tuning and Power Delivery

Turbocharger optimization delivers the foundation for rally car power, with most modern rally engines producing between 300-380 horsepower from compact 1.6-liter units. Engineers recalibrate ECU mapping to maximize torque delivery across the entire rev range, ensuring drivers have instant power available when handling tight corners or steep climbs.

Anti-lag systems maintain turbo pressure during gear shifts and throttle lift situations, eliminating the dreaded turbo lag that could cost precious seconds. These systems inject fuel and ignite it in the exhaust manifold, keeping the turbine spinning at optimal speeds.

Intake and exhaust modifications optimize airflow through high-flow air filters, larger intercoolers, and free-flowing exhaust systems. Rally teams often use ceramic-coated exhaust components to reduce heat buildup and maintain consistent performance throughout long stages.

Fuel system upgrades include high-capacity fuel pumps, larger injectors, and specialized fuel management systems that ensure consistent power delivery regardless of the car’s orientation on steep terrain or during jumps.

Suspension Systems for Rough Terrain

Long-travel suspension provides the cornerstone of rally car handling, with typical wheel travel ranging from 8-12 inches compared to 4-6 inches in standard vehicles. This extended travel allows cars to maintain tire contact over rough surfaces while absorbing massive impacts from jumps and bumps.

Adjustable dampers feature multiple compression and rebound settings that crews can tune between stages based on terrain conditions. Top-tier rally cars use electronic dampers with real-time adjustment capabilities, automatically adapting to surface changes.

Reinforced components replace standard suspension parts with motorsport-grade alternatives made from stronger materials like chromoly steel or titanium. These upgrades include heavy-duty control arms, reinforced mounting points, and upgraded bushings that withstand extreme forces.

Ground clearance optimization balances aerodynamic efficiency with terrain clearance, typically ranging from 150-200mm depending on stage requirements. Teams adjust ride height using threaded coilover systems for quick setup changes.

Transmission and Drivetrain Upgrades

Sequential gearboxes enable lightning-fast gear changes without using a clutch pedal, allowing drivers to shift in approximately 50 milliseconds. These transmissions feature dog engagement rather than synchromesh, providing positive gear engagement under extreme conditions.

All-wheel-drive systems distribute power between front and rear axles through sophisticated center differentials, with most modern rally cars using active differentials that adjust power distribution in real time. Electronic systems monitor wheel slip and steering input to optimize traction.

Limited-slip differentials in both front and rear axles prevent wheel spin on loose surfaces while maintaining steering control. These mechanical or electronic systems automatically transfer torque to the wheel with better grip.

Drivetrain reinforcement includes upgraded driveshafts, CV joints, and axles designed to handle the increased power and shock loads from rough terrain. Rally teams often carry spare driveshafts as these components face extreme stress during competition.

Iconic Rally Car Models That Dominated the Sport

Rally history showcases legendary vehicles that transformed motorsport through their engineering excellence and championship victories. These machines didn’t just compete in rallies—they redefined what rally cars could achieve.

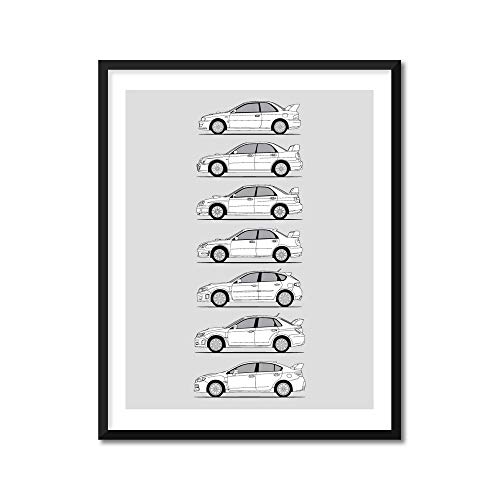

Subaru Impreza WRX STI Legacy

Subaru’s Impreza WRX STI created a rally dynasty that spanned over two decades of Industry Rally Championship competition. Colin McRae’s spectacular driving style perfectly complemented the Impreza’s boxer engine and symmetrical all-wheel-drive system, delivering three consecutive manufacturer’s championships from 1995 to 1997.

Production models brought rally technology directly to enthusiast driveways through the WRX and STI variants. We’ve seen how Subaru’s commitment to all-wheel-drive performance made these cars accessible to everyday drivers who wanted genuine rally car capabilities.

Championship success extended beyond the 1990s with Richard Burns securing the 2001 driver’s title and Petter Solberg claiming victory in 2003. Multiple iterations of the Impreza platform proved their versatility across different rally regulations and surface conditions.

Blue and gold livery became synonymous with rally excellence as the Impreza’s distinctive appearance dominated television coverage worldwide. This visual identity helped establish Subaru as a premium performance brand in markets where rally success translated to showroom appeal.

Mitsubishi Lancer Evolution Dynasty

Mitsubishi’s Lancer Evolution series dominated the Industry Rally Championship through four consecutive manufacturer’s titles from 1996 to 1999. Tommi Mäkinen’s exceptional skill behind the wheel showcased the Evolution’s sophisticated 4G63 turbocharged engine and Super All Wheel Control system.

Evolution models revolutionized active differentials with their AYC (Active Yaw Control) technology that could distribute torque between rear wheels during cornering. We’ve observed how this innovation gave drivers unprecedented control over vehicle dynamics on challenging rally stages.

Homologation requirements produced some of motorsport’s most capable road cars through Evolution III, IV, V, and VI models. Each generation incorporated lessons learned from rally competition into production vehicles that delivered genuine competition-bred performance.

Group A regulations perfectly suited the Evolution platform’s inherent strengths in handling and powertrain integration. Mitsubishi’s engineering team optimized every component for rally conditions while maintaining reliability standards required for championship campaigns.

Ford Focus RS Rally Heritage

Ford’s Focus RS established a new era of rally dominance when the Industry Rally Car regulations replaced Group A in 1997. Marcus Grönholm and Carlos Sainz Sr. piloted the Focus to multiple championship victories while demonstrating the platform’s exceptional versatility across diverse rally conditions.

Industry Rally Car technology transformed the Focus into a purpose-built competition machine featuring a 2.0-liter turbocharged engine producing over 300 horsepower. Advanced suspension systems and aerodynamic packages optimized the car for maximum performance on tarmac and gravel surfaces.

Sébastien Loeb’s early career benefited from the Focus platform’s forgiving handling characteristics and robust construction during his development years. This foundation helped establish driving techniques that would later contribute to his record-breaking nine consecutive championship titles with different manufacturers.

Production Focus RS models inherited rally-developed technologies including Revoknuckle front suspension and sophisticated torque vectoring systems. We’ve seen how Ford successfully translated competition innovations into road cars that delivered authentic rally car experiences for enthusiast drivers.

Understanding Rally Car Categories and Classes

Rally racing organizes vehicles into distinct categories that ensure fair competition and maintain safety standards across different levels of motorsport participation.

Group A Rally Cars

Group A rally cars represent the foundation of international rally competition, featuring production-based vehicles with exact modification limits. These cars maintain their original chassis structure and body shell while allowing engineers to enhance performance within strict regulatory boundaries. We see manufacturers like Subaru, Mitsubishi, and Ford developing Group A homologation specials that showcase advanced all-wheel-drive technology and turbocharged engines.

Engine modifications in Group A specifications include increased boost pressure, modified intake systems, and performance exhaust configurations that extract maximum power from production-based powerplants. Suspension systems receive comprehensive upgrades with rally-exact dampers, springs, and anti-roll bars that transform handling characteristics for competitive use. Weight reduction strategies remove unnecessary interior components, sound deadening materials, and replace standard parts with lightweight alternatives while maintaining structural integrity.

Safety requirements mandate full roll cage installation, fire suppression systems, and competition-grade seats that protect drivers during high-speed competition. These regulations ensure Group A rally cars maintain accessibility for privateers and smaller teams while providing competitive performance levels.

Industry Rally Championship Specifications

Industry Rally Championship cars operate under the current Rally1 regulations that represent the pinnacle of rally car technology and performance. Rally1 vehicles feature hybrid powertrains combining 1.6-liter turbocharged engines with electric motor assistance that delivers approximately 500 horsepower total output. Manufacturers including Toyota, Hyundai, and Ford develop these sophisticated machines with advanced aerodynamic packages and cutting-edge suspension systems.

Technical specifications require teams to use standardized hybrid units, control electronics, and safety systems that level the competitive playing field while maintaining manufacturer identity. Rally1 cars incorporate active center differentials, sophisticated traction control systems, and paddle-shift sequential gearboxes that optimize power delivery across varying surface conditions.

Championship regulations mandate exact weight minimums, aerodynamic restrictions, and homologation requirements that balance performance with cost control measures. These cars represent the ultimate expression of rally engineering excellence, combining maximum performance with rigorous safety standards for top-level international competition.

Regional and National Class Systems

Regional rally championships organize vehicles into classes based on engine displacement, drivetrain configuration, and modification levels that accommodate diverse budgets and skill levels. Class structures typically range from showroom stock categories for beginners to highly modified open class vehicles that approach professional specifications.

| Class Category | Engine Limit | Drivetrain | Modification Level |

|---|---|---|---|

| Stock/Showroom | Production | Any | Minimal |

| Prepared | 2.0L Turbo | AWD Preferred | Moderate |

| Modified | 2.5L+ | AWD Required | Extensive |

| Open | Unlimited | AWD Required | Full Competition |

National championships establish exact rules governing tire compounds, safety equipment requirements, and technical inspections that ensure competitive integrity. Events organize starting orders, timing procedures, and scoring systems that create exciting competition across multiple vehicle categories simultaneously.

Local rally organizations often create grassroots classes that welcome older vehicles, budget builds, and entry-level competitors who want to experience rally competition without major financial investment. These systems provide pathways for drivers to progress through different categories as their skills and budgets develop over time.

How Rally Cars Handle Different Terrain Types

Rally cars master diverse terrain challenges through specialized adaptations that transform their performance characteristics for each surface type. We’ll explore how these engineering marvels adapt to gravel, tarmac, and winter conditions.

Gravel Stage Adaptations

Suspension tuning becomes crucial for gravel stages as rally cars require increased ground clearance and softer damper settings to absorb constant impacts. Teams raise the ride height by 20-30mm compared to tarmac configurations, allowing wheels to compress over rocks and ruts without bottoming out the chassis.

Tire selection shifts to specialized gravel compounds featuring aggressive tread patterns and reinforced sidewalls that resist punctures from sharp stones. We see teams using Michelin or Pirelli gravel tires with deeper lugs that dig into loose surfaces while maintaining lateral grip through corners.

Aerodynamic packages get modified with simplified wing configurations since high downforce becomes less effective on loose surfaces. Rally teams remove complex front splitters and reduce rear wing angles to prevent damage from flying debris while maintaining basic stability at speed.

Engine mapping receives adjustments for improved torque delivery in the mid-range power band where gravel stages demand consistent traction management. Power delivery curves become smoother to prevent wheel spin that would dig the car into loose gravel rather than providing forward momentum.

Tarmac Racing Configurations

Suspension systems transform completely for tarmac stages using lower ride heights and stiffer spring rates that maximize tire contact patch consistency. Teams drop the car height by 15-25mm and increase damper compression settings to maintain precise handling through high-speed corners.

Aerodynamic efficiency reaches maximum importance on tarmac where rally cars can use full downforce packages including aggressive front splitters and large rear wings. These components generate important grip at speeds exceeding 120 mph on smooth asphalt surfaces.

Tire compounds switch to slick or semi-slick designs with softer rubber formulations that heat up quickly and provide maximum grip on clean pavement. Tarmac tires feature minimal tread depth compared to gravel variants, prioritizing contact patch size over debris resistance.

Brake cooling receives enhanced attention through larger brake ducts and ventilated disc designs since tarmac stages feature more aggressive braking zones than gravel events. Teams install additional cooling channels to prevent brake fade during long downhill sections.

Snow and Ice Performance Setup

Studded tire technology becomes essential for winter rally stages where cars use specialized rubber compounds embedded with metal studs that bite into ice surfaces. These tires feature up to 384 studs per tire, strategically positioned to maximize traction while maintaining tire longevity.

Weight distribution shifts through strategic ballast placement that moves the center of gravity lower and more rearward for improved stability on slippery surfaces. Rally teams add up to 50kg of ballast in exact chassis locations to optimize handling characteristics.

Differential settings receive important modifications with more open configurations that allow wheels to rotate at different speeds when handling icy corners. Limited slip differentials get adjusted to reduce locking percentages, preventing the car from pushing wide on frozen surfaces.

Visibility enhancements include specialized lighting packages with LED arrays and heated windshield systems that maintain clear vision during snowstorms. Rally cars feature up to six additional spotlights and windshield heating elements that prevent ice buildup during competition.

The Technology Behind Modern Rally Cars

Modern rally technology has evolved far beyond basic engine modifications and suspension upgrades. We’re witnessing an era where sophisticated electronic systems and cutting-edge data analysis transform how rally cars perform across challenging terrain.

Electronic Differential Systems

Electronic differential systems represent the pinnacle of traction control technology in modern rally cars. We see these advanced systems replacing traditional mechanical differentials with computer-controlled units that can adjust torque distribution in milliseconds. Active torque vectoring allows drivers to maintain optimal grip on surfaces ranging from loose gravel to wet tarmac.

Central electronic control units monitor wheel speeds, steering angle, and throttle position to determine the ideal power distribution. Variable torque split systems can send anywhere from 0% to 100% of available power to individual wheels based on real-time conditions. Rally cars like the Toyota GR Yaris WRC use three differential systems working in harmony: front, rear, and center differentials that communicate through a central ECU.

Regenerative braking integration adds another layer of complexity to modern electronic differential systems. Electric motors in hybrid rally cars can provide negative torque to exact wheels, creating additional control during corner entry. Teams can program these systems with dozens of different maps customized to exact stages, weather conditions, and driver preferences.

Data Acquisition and Telemetry

Data acquisition systems in rally cars capture thousands of parameters per second to optimize performance and ensure reliability. We observe teams utilizing up to 200 sensors throughout the vehicle monitoring everything from tire temperatures to suspension travel. Real-time telemetry transmission allows engineers in the service park to track car performance during stages and make informed setup decisions.

GPS-based data logging provides precise location information synchronized with performance metrics. Engineers can analyze exactly where drivers gain or lose time on exact corners by overlaying throttle position, brake pressure, and steering angle data. Memory cards store complete stage data for post-event analysis, creating detailed performance databases that teams reference for future events.

Predictive maintenance algorithms use sensor data to identify potential component failures before they occur. Oil pressure fluctuations, bearing temperatures, and vibration patterns help teams prevent costly retirements during competition. Rally teams like Hyundai Motorsport process over 100 GB of data per rally weekend, using machine learning algorithms to identify performance optimization opportunities.

Driver feedback integration combines subjective input with objective data to create comprehensive setup strategies. Digital displays inside the cockpit show real-time information including split times, pace notes, and system status alerts.

Advanced Aerodynamic Features

Advanced aerodynamic systems in rally cars focus on creating downforce while maintaining cooling efficiency across varied terrain. We find active aerodynamic elements becoming increasingly sophisticated, with adjustable rear wings and front splitters that adapt to different stage types. Rally1 cars feature complex undertray designs that generate ground effect downforce while protecting vital components from debris.

Computational fluid dynamics modeling allows teams to optimize bodywork for exact rally conditions. Engineers design aerodynamic packages that balance downforce generation with cooling requirements, ensuring engines and brakes operate within optimal temperature ranges. Carbon fiber body panels reduce weight while providing the structural rigidity needed for aerodynamic consistency at high speeds.

Cooling duct optimization represents a critical aspect of rally car aerodynamics. Strategic air intake placement directs airflow to radiators, brake ducts, and electronic component cooling systems. Rally cars competing in hot climates like Rally Mexico require significantly different aerodynamic configurations compared to snow events like Rally Sweden.

Vortex generators and air dams help manage airflow around wheel wells and suspension components. These small aerodynamic devices reduce drag while improving stability during high-speed sections. Teams conduct extensive wind tunnel testing to validate CFD models, ensuring aerodynamic performance translates effectively to real-industry rally conditions.

Famous Rally Car Drivers and Their Machines

Rally car excellence reaches its peak when exceptional drivers unite with perfectly engineered machines. Throughout the sport’s history, certain partnerships between drivers and their vehicles have created legendary moments that continue to inspire rally enthusiasts worldwide.

Legendary Driver-Car Combinations

Sébastien Loeb and Citroën Xsara WRC dominated rally racing from 2004 to 2012 with an unprecedented nine consecutive Industry Rally Championship titles. Loeb’s precision driving style perfectly complemented the Xsara’s sophisticated electronic systems and aerodynamic design. Together they won 78 WRC events, establishing a record that remains unmatched in rally history.

Tommi Mäkinen and Mitsubishi Lancer Evolution created one of rally’s most successful partnerships during the late 1990s. Mäkinen’s four consecutive WRC titles from 1996 to 1999 showcased the Evolution’s advanced active differential technology. His ability to extract maximum performance from the Lancer’s all-wheel-drive system made them nearly unstoppable on gravel stages.

Walter Röhrl and Audi Quattro revolutionized rally racing in the early 1980s with their groundbreaking all-wheel-drive technology. Röhrl’s technical expertise allowed him to fully exploit the Quattro’s traction advantages on various surfaces. Their partnership proved that all-wheel-drive systems could dominate rally competition, changing the sport forever.

Richard Burns and Subaru Impreza WRC formed a formidable combination that earned the 2001 Industry Rally Championship. Burns’ smooth driving technique perfectly matched the Impreza’s balanced handling characteristics. His victory represented the culmination of Subaru’s rally development program and established the Impreza as a rally icon.

Championship-Winning Partnerships

Marcus Grönholm and Peugeot 206 WRC claimed multiple victories throughout the early 2000s with their aggressive yet calculated approach. Grönholm’s fearless driving style maximized the 206’s exceptional chassis balance and power delivery. Their partnership resulted in many rally wins and consistently strong championship standings.

Colin McRae and Subaru Impreza WRC became synonymous with spectacular rally driving during the 1990s. McRae’s attacking style pushed the Impreza beyond its limits, creating some of rally’s most memorable moments. His 1995 Industry Rally Championship victory marked Britain’s first WRC title and elevated both driver and machine to legendary status.

Petter Solberg and Subaru Impreza WRC continued Subaru’s championship tradition with their 2003 Industry Rally Championship triumph. Solberg’s adaptability across different terrain types showcased the Impreza’s versatility and engineering excellence. Their success demonstrated how driver skill and machine capability combine to achieve championship glory.

Sébastien Ogier and Volkswagen Polo R WRC dominated rally racing from 2013 to 2016 with four consecutive championship victories. Ogier’s consistency and technical precision perfectly utilized the Polo’s advanced aerodynamics and hybrid technology. Their partnership established Volkswagen as a major force in modern rally competition before the manufacturer’s withdrawal from the sport.

Rising Stars in Modern Rally Racing

Kalle Rovanperä and Toyota GR Yaris Rally1 represent the future of rally racing with their impressive performances in the current WRC season. Rovanperä’s youth and natural talent complement the GR Yaris’s hybrid powertrain and advanced safety systems. At just 22 years old, he became the youngest ever WRC champion in 2022, showcasing exceptional skill behind the wheel of Toyota’s cutting-edge rally machine.

Ott Tänak and Hyundai i20 N Rally1 continue pushing the boundaries of modern rally performance with their aggressive driving approach. Tänak’s experience and technical feedback help optimize the i20’s sophisticated electronic systems and aerodynamic package. Their partnership demonstrates how veteran drivers can adapt to new hybrid technology while maintaining competitive edge.

Elfyn Evans and Toyota GR Yaris Rally1 consistently deliver strong results through their methodical and calculated racing strategy. Evans’ smooth driving style maximizes the GR Yaris’s reliability and performance across diverse rally conditions. His ability to extract consistent speed from the hybrid powertrain makes him a formidable competitor in current championship battles.

Craig Breen and Ford Puma Rally1 showcase the potential of Ford’s return to top-level rally competition. Breen’s enthusiastic approach and technical knowledge help develop the Puma’s performance capabilities. Their collaboration represents Ford’s commitment to modern rally technology and the next generation of championship-winning partnerships.

Cost Breakdown of Building a Competitive Rally Car

Building a competitive rally car requires important financial investment across multiple areas. We’ll examine the major cost categories from initial purchase through ongoing race preparation to help you understand the true expense of rally competition.

Initial Purchase and Base Modifications

Base Vehicle Acquisition costs vary dramatically depending on your chosen platform and class requirements. We typically see budget allocations ranging from $15,000 to $40,000 for suitable donor vehicles like Subaru WRX STIs or Mitsubishi Lancer Evolutions. Popular rally platforms command premium prices due to their proven motorsport heritage and available aftermarket support.

Engine and Drivetrain Modifications represent the largest single expense category for most builds. Turbocharger upgrades, forged internals, and ECU tuning packages typically cost $20,000 to $35,000 for competitive power levels. Sequential transmission conversions add another $15,000 to $25,000, while differential and driveline reinforcements require $8,000 to $12,000 in additional investment.

Suspension System Upgrades demand substantial financial commitment for rally-exact components. Long-travel suspension kits with adjustable dampers cost $12,000 to $18,000 for quality setups. Specialized rally springs, anti-roll bars, and mounting hardware add another $3,000 to $5,000 to achieve proper handling characteristics across diverse terrain types.

| Modification Category | Budget Range | Premium Range |

|---|---|---|

| Base Vehicle | $15,000 | $40,000 |

| Engine/Drivetrain | $20,000 | $35,000 |

| Suspension | $12,000 | $18,000 |

| Body/Aero | $8,000 | $15,000 |

Safety Equipment Investment

Roll Cage Construction forms the foundation of rally car safety systems with costs ranging from $8,000 to $15,000 for professional fabrication and installation. We recommend chromoly steel construction meeting FIA specifications, which provides superior strength-to-weight ratios compared to mild steel alternatives. Custom fabrication ensures proper fit and maximum protection for your exact vehicle platform.

Fire Suppression Systems require careful specification and professional installation to meet competition standards. Automatic fire suppression systems cost $2,500 to $4,000, while manual backup systems add another $1,000 to $1,500. We prioritize dual-activation systems that provide both heat-triggered and driver-operated suppression capabilities for comprehensive fire protection.

Driver Safety Equipment represents ongoing investment in personal protective gear that meets evolving safety standards. FIA-approved helmets cost $800 to $2,500 depending on features and certification levels. Six-point safety harnesses require $400 to $800, while fire-resistant racing suits range from $600 to $1,500. HANS devices add $800 to $1,200 but provide critical head and neck protection during impacts.

Window Nets and Interior Safety Features complete the safety equipment package with costs typically ranging from $1,500 to $3,000. Quick-release steering wheels, fire extinguisher mounting, and emergency shut-off switches ensure driver safety and meet technical regulations across different rally series.

Ongoing Maintenance and Race Preparation

Tire Costs represent the most important recurring expense for rally competition. We typically budget $2,000 to $4,000 per event for tire sets, depending on stage length and surface conditions. Gravel tires wear faster than tarmac compounds, while studded winter tires command premium prices due to specialized construction requirements.

Service and Rebuild Intervals require systematic planning to maintain competitive reliability. Engine rebuilds cost $8,000 to $15,000 depending on damage levels and component replacement needs. Transmission services range from $2,000 to $5,000, while differential rebuilds typically cost $1,500 to $3,000. We recommend establishing rebuild schedules based on competition miles rather than calendar intervals.

Event Preparation Costs include many smaller expenses that accumulate quickly throughout the season. Parts inventory, fluids, filters, and consumables typically cost $1,500 to $3,000 per event. Transportation, entry fees, and accommodation expenses add another $2,000 to $5,000 depending on event location and duration.

Crash Damage Reserves represent unavoidable reality in rally competition where contact with barriers, trees, and rocks occurs regularly. We recommend maintaining $10,000 to $20,000 in reserve funds for major repairs, as single incidents can require extensive bodywork, suspension replacement, or engine rebuilds. Insurance coverage rarely covers competition damage, making self-funding essential for continued participation.

How to Get Started in Rally Car Racing

Breaking into rally car racing opens doors to one of motorsport’s most exciting disciplines. We’ll guide you through the essential steps to begin your rally career safely and effectively.

Entry-Level Rally Car Options

Start with affordable production based vehicles that offer proven reliability and extensive parts availability. Subaru Impreza models from the late 1990s and early 2000s provide excellent all wheel drive foundations for beginners, typically costing between $8,000 and $15,000 for suitable examples. Ford Focus hatchbacks deliver front wheel drive simplicity with strong aftermarket support and lower initial investment requirements of $5,000 to $10,000.

Consider regional class regulations before making your vehicle selection. Many rally organizations offer Showroom Stock categories where modifications remain minimal, allowing you to compete with basic safety equipment like roll cages, racing seats, and harnesses. Production Class vehicles permit limited engine and suspension modifications while maintaining street legal status.

Budget approximately $15,000 to $25,000 for essential safety modifications on entry level cars. Roll cage installation represents your largest single expense at $5,000 to $8,000, while fire suppression systems add another $2,000 to $3,000. Racing seats, harnesses, and communication equipment contribute an additional $3,000 to $5,000 to your initial preparation costs.

Finding Local Rally Events

Connect with regional rally organizations through the Rally America or American Rally Association websites. These sanctioning bodies maintain comprehensive event calendars showing rallysprint events, stage rallies, and rallycross competitions throughout the racing season. Most regions host 6 to 12 events annually, providing multiple opportunities to gain competitive experience.

Attend events as a spectator before committing to competition participation. Rally events welcome spectators at service areas and designated viewing points, allowing you to observe preparation procedures, meet competitors, and understand event logistics. Many experienced teams welcome newcomers and provide valuable insights into getting started.

Volunteer as crew members or officials to learn rally operations from the inside. Stage marshals, timing officials, and service crew positions offer hands on experience with rally procedures while building relationships within the rally community. These connections often lead to mentorship opportunities and access to used equipment at reasonable prices.

Join local sports car clubs that organize rallycross events. Rallycross provides an affordable entry point using minimally modified street cars on closed courses with cones and barriers. Events typically cost $40 to $60 per entry and require only basic safety equipment like helmets and long pants.

Building Your Racing Skills

Enroll in performance driving schools that specialize in rally techniques. DirtFish Rally School in Washington and Team O’Neil Rally School in New Hampshire offer comprehensive programs covering car control, pace note reading, and advanced driving techniques. Two day courses range from $1,800 to $2,500 and provide essential foundation skills.

Practice car control techniques in safe, controlled environments. Empty parking lots allow you to practice handbrake turns, weight transfer management, and threshold braking without risking property damage or legal consequences. Focus on smooth inputs and maintaining vehicle balance rather than outright speed.

Develop pace note reading skills through co driver training programs. Effective communication between driver and co driver determines rally success, requiring precise timing and clear delivery of corner information. Practice sessions using rally videos and timing equipment help develop these critical communication skills.

Participate in rallycross events to build competition experience. These autocross style events on dirt or gravel surfaces provide wheel to wheel racing experience without the commitment and expense of stage rallying. Regular participation develops racecraft, car setup knowledge, and mechanical troubleshooting abilities essential for rally success.

Conclusion

Rally cars represent the pinnacle of automotive engineering where raw power meets precision craftsmanship. We’ve explored how these remarkable machines push the boundaries of what’s possible when human skill combines with cutting-edge technology.

Whether you’re drawn to the thunderous roar of a turbocharged engine or the split-second decision-making required to navigate treacherous terrain at breakneck speeds rally racing offers an unmatched adrenaline experience. The sport continues to evolve with new technologies and talented drivers emerging each season.

For those inspired to take the wheel we’ve outlined the pathways from spectator to competitor. The rally community welcomes newcomers with open arms and there’s never been a better time to discover why we’re so passionate about this incredible motorsport discipline.

Frequently Asked Questions

What makes rally cars different from regular cars?

Rally cars are specially modified vehicles designed for extreme motorsport conditions. They feature all-wheel-drive systems, long-travel suspension, reinforced roll cages, powerful engines, and quick-shifting transmissions. These modifications enable them to handle challenging terrains like gravel, snow, and tarmac at high speeds while maintaining driver safety and vehicle durability.

How much does it cost to build a competitive rally car?

Building a competitive rally car requires significant investment, ranging from tens of thousands to hundreds of thousands of dollars. Costs include vehicle acquisition, safety modifications, engine upgrades, suspension systems, and ongoing maintenance. Entry-level builds start around $20,000-30,000, while professional-level cars can exceed $200,000.

What are the best entry-level rally cars for beginners?

Popular entry-level rally cars include the Subaru Impreza, Ford Focus, Volkswagen Golf, and Honda Civic. These vehicles offer affordable acquisition costs, readily available parts, strong aftermarket support, and proven rally performance. They provide excellent platforms for learning rally driving skills while managing budget constraints effectively.

What safety equipment is required in rally cars?

Essential safety equipment includes a certified roll cage, racing harnesses, fire suppression system, racing seats, driver helmets, and protective clothing. Additionally, rally cars must have emergency shut-off switches, first aid kits, and communication systems. All safety equipment must meet FIA (Fédération Internationale de l’Automobile) standards for competition approval.

How do rally cars handle different terrain types?

Rally cars adapt to various terrains through specialized modifications. For gravel stages, they use knobby tires and raised suspension. Tarmac events require slick tires and lower ride height. Snow conditions demand studded tires and adjusted differential settings. Each terrain type requires specific tire compounds, suspension tuning, and aerodynamic adjustments for optimal performance.

What are the most iconic rally car models?

Legendary rally cars include the Subaru Impreza WRX STI, Mitsubishi Lancer Evolution, Audi Quattro, Lancia Delta Integrale, and Ford Escort RS Cosworth. These models dominated various rally championships and showcased groundbreaking technologies like all-wheel-drive systems, turbo engines, and advanced aerodynamics that influenced modern rally car development.

How can beginners get started in rally racing?

Beginners should start by attending local rally events as spectators, joining rally clubs, and volunteering at events. Next, consider taking performance driving courses, participating in rallycross events, and gradually building or purchasing an entry-level rally car. Connecting with experienced drivers and mechanics provides valuable mentorship and learning opportunities.

What skills are essential for rally driving?

Key rally driving skills include car control techniques, pace note reading, quick decision-making, and risk assessment. Drivers must master throttle control, braking techniques, and steering precision while navigating at high speeds. Mental skills like concentration, spatial awareness, and the ability to process information quickly are equally important for success.