When we’re shopping for new wheels or need to replace damaged rims, understanding lug patterns becomes crucial for a perfect fit. The lug pattern (also called bolt pattern) determines whether a wheel will properly mount to your vehicle’s hub, and getting it wrong can lead to safety issues and costly mistakes.

We’ve all been there – staring at a beautiful set of wheels online or at the tire shop, wondering if they’ll actually fit our car or truck. Measuring your rim’s lug pattern isn’t rocket science, but it does require knowing the right technique and having the proper tools. Whether you’re dealing with a 4-lug, 5-lug, 6-lug, or 8-lug pattern, each configuration has its own measurement method.

Getting accurate measurements saves money and ensures your safety on the road. We’ll walk you through the step-by-step process to measure your lug pattern correctly, so you can shop for wheels with complete confidence and avoid the frustration of ordering incompatible rims.

What Is a Rim Lug Pattern and Why It Matters

Rim lug patterns represent the exact arrangement of bolt holes that connect wheels to vehicle hubs. We define this critical measurement using two components: the number of bolt holes and the diameter of the circle formed by those holes’ centers.

Understanding lug patterns prevents costly purchasing mistakes when selecting replacement wheels or aftermarket rims. The pattern determines whether a wheel fits your vehicle’s hub assembly properly, ensuring safe operation and optimal performance.

Common lug patterns include configurations like 4×100, 5×114.3, 6×139.7, and 8×165.1. The first number indicates bolt hole quantity while the second represents the pitch circle diameter in millimeters.

Standard Lug Pattern Configurations:

| Vehicle Type | Common Patterns | Typical Applications |

|---|---|---|

| Compact Cars | 4×100, 4×108 | Honda Civic, Ford Focus |

| Mid-size Sedans | 5×114.3, 5×120 | Toyota Camry, BMW 3 Series |

| Trucks/SUVs | 6×139.7, 8×165.1 | Chevrolet Silverado, Ford F-250 |

Incorrect lug patterns create safety hazards including wheel detachment, uneven tire wear, and compromised braking performance. We emphasize that even minor measurement discrepancies can prevent proper wheel installation.

Manufacturing standards require precise tolerances for lug pattern measurements. European vehicles often use metric measurements while American manufacturers may specify imperial units, creating potential confusion during wheel selection.

Professional mechanics rely on lug pattern accuracy to ensure proper torque specifications and load distribution across all mounting points. This precision directly impacts vehicle stability during acceleration, braking, and cornering maneuvers.

Tools You’ll Need to Measure Rim Lug Pattern

Measuring rim lug patterns accurately requires exact tools that deliver precise measurements. A ruler or measuring tape serves as the primary tool for determining the bolt circle diameter across different lug configurations. Straightedges or calipers provide enhanced precision when measuring between lug hole centers, particularly for 5-lug patterns where exact measurements prove critical.

Marking tools like pencils or markers help identify the exact center points of each lug hole before taking measurements. Digital calipers offer superior accuracy compared to standard rulers, especially when working with metric measurements common in European vehicles. Measuring tape works effectively for larger bolt patterns found on trucks and SUVs with 6-lug or 8-lug configurations.

| Tool Type | Purpose | Accuracy Level |

|---|---|---|

| Ruler/Measuring Tape | Basic diameter measurement | Standard |

| Digital Calipers | Precise lug spacing | High precision |

| Straightedge | Center-to-center alignment | Enhanced accuracy |

| Pencil/Marker | Center point marking | Visual reference |

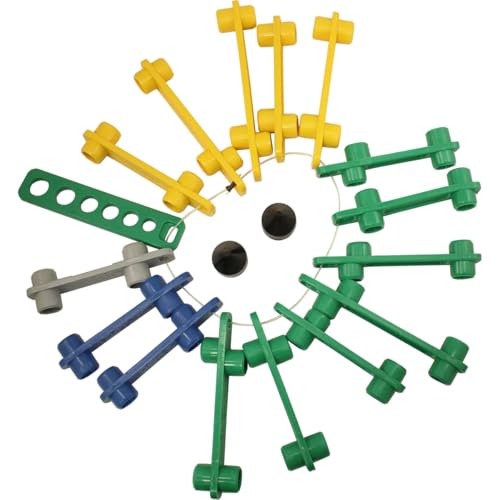

Professional mechanics often use specialized lug pattern gauges that simplify the measurement process across multiple bolt configurations. These gauges eliminate calculation errors and provide instant pattern identification for common sizes like 4×100, 5×114.3, and 6×139.7. Having multiple measurement tools available ensures verification of results and reduces the risk of incorrect wheel purchases.

How to Identify the Number of Lug Holes

Counting lug holes represents the first step in measuring rim lug patterns accurately. We start by visually examining the wheel to count each bolt hole designed for lug nuts or bolts. Most wheel configurations feature 4, 5, 6, or 8 lug holes arranged in a circular pattern around the center hub.

Visual inspection provides the most straightforward method for determining lug hole quantity. Each hole appears as a circular opening where lug bolts or nuts secure the wheel to the vehicle hub. We recommend counting twice to ensure accuracy since miscounting affects the entire measurement process.

Vehicle documentation offers an alternative verification method when visual counting proves challenging. Owner’s manuals contain technical specifications that list the exact number of lugs for each vehicle model. Manufacturer documentation eliminates guesswork and provides authoritative confirmation of lug hole quantities.

Common lug patterns follow exact numbering conventions that simplify identification:

- 4-lug patterns appear on compact cars and smaller vehicles

- 5-lug patterns dominate mid-size sedans and sports cars

- 6-lug patterns characterize pickup trucks and larger SUVs

- 8-lug patterns exist on heavy-duty trucks and commercial vehicles

Marking each lug hole during counting prevents confusion and ensures complete coverage. We suggest using a pencil or marker to number each hole sequentially as we count. This technique proves especially valuable on wheels with higher lug counts where visual tracking becomes more difficult.

Double verification confirms our initial count and catches potential errors before proceeding to diameter measurements. Counting from different starting positions or asking another person to verify helps eliminate counting mistakes that could compromise wheel compatibility.

Measuring 4-Lug and 6-Lug Patterns

Measuring even numbered lug patterns requires a straightforward center to center approach that differs from odd numbered configurations. We’ll demonstrate the exact techniques for both 4 lug and 6 lug patterns to ensure accurate measurements.

4-Lug Pattern Measurement Method

Select two opposite studs positioned directly across from each other on the wheel. Measuring from the center of one stud to the center of the opposite stud provides the bolt circle diameter measurement. Position your ruler or caliper carefully to ensure contact with the center points of each selected stud.

The measurement gives you the bolt circle diameter expressed as 4 times the diameter in millimeters such as 4×100mm or 4×114.3mm. Record this measurement precisely since even small variations can affect wheel compatibility. Double check your measurement by selecting a different pair of opposite studs to verify consistency.

Secure the wheel firmly during measurement to prevent movement that could compromise accuracy. Use digital calipers when available as they provide more precise readings than standard rulers or measuring tapes.

6-Lug Pattern Measurement Method

Choose two studs positioned directly across from each other following the same principle used for 4 lug patterns. Measure the distance from the center of one selected stud to the center of the opposite stud using your measuring tool. Ensure your measurement line passes through the center of the wheel hub for maximum accuracy.

The measurement provides the bolt circle diameter expressed as 6 times the diameter in millimeters such as 6×139.7mm or 6×135mm. Common 6 lug patterns include 6×139.7mm found on many trucks and SUVs and 6×135mm used on certain Ford vehicles. Verify your measurement by repeating the process with a different pair of opposite studs.

Maintain steady positioning throughout the measurement process since 6 lug wheels often have larger diameters that can make precise measurement more challenging. Consult your vehicle’s manual or specifications if you encounter difficulty identifying the correct bolt pattern measurement.

Measuring 5-Lug and 8-Lug Patterns

Odd and even lug configurations require different measurement approaches due to their geometric arrangements. We’ll examine the exact techniques for both 5-lug and 8-lug patterns to ensure accurate bolt circle diameter calculations.

5-Lug Pattern Measurement Method

5-lug patterns present unique measurement challenges because the lugs aren’t positioned directly opposite each other. We start by selecting any single lug hole as our reference point for the measurement process.

Measuring from the center of this chosen lug hole to the outer edge of the farthest lug hole provides the bolt circle diameter. This farthest point represents the lug hole positioned across the circular pattern rather than an adjacent one.

The measurement obtained becomes the bolt circle diameter that passes through all lug hole centers. A typical result like “5×114.3” indicates 5 lugs arranged in a 114.3 mm diameter circle pattern.

Digital calipers deliver the most precise measurements for 5-lug patterns due to the center-to-outer-edge technique required. We recommend verifying measurements twice to confirm accuracy before proceeding with wheel selection.

8-Lug Pattern Measurement Method

8-lug patterns offer simpler measurement procedures because of their even-numbered configuration with directly opposite lug holes. We identify two lug holes positioned directly across from each other on the circular pattern.

Measuring from the center of one lug hole to the center of its opposite counterpart gives us the bolt circle diameter. This center-to-center measurement represents the standard approach for all even-numbered lug patterns.

Pattern descriptions follow the format “8×165.1” where 8 indicates the lug count and 165.1 mm represents the bolt circle diameter. Commercial trucks and heavy-duty vehicles commonly feature 8-lug patterns with this exact measurement.

Precision remains critical even with the straightforward measurement technique for 8-lug patterns. We always measure in millimeters and consult vehicle specifications when available to confirm our calculated measurements match manufacturer standards.

Common Rim Lug Pattern Sizes by Vehicle Type

Different vehicle categories typically use exact lug patterns that match their weight requirements and design specifications. Understanding these standard patterns helps us identify what to expect when measuring our vehicle’s rims.

Compact and midsize cars commonly feature 4×100, 4×108, 5×100, or 5×114.3 patterns. These smaller configurations accommodate the lighter weight and reduced stress requirements of passenger vehicles. Most Honda Civic models use 5×114.3 patterns, while many European compact cars use 4×100 configurations.

Full-size cars and SUVs frequently employ 5×114.3 or 5×120 patterns to handle increased vehicle weight and performance demands. BMW vehicles often use 5×120 patterns, whereas many American full-size sedans and crossovers rely on 5×114.3 configurations.

Light trucks and some SUVs commonly use 6×139.7 (equivalent to 6×5.5 inches) or 8×165.1 (equivalent to 8×6.5 inches) patterns. Chevrolet Silverado and Ford F-150 models typically feature these heavy-duty configurations to support higher payload capacities and towing requirements.

Trailers often use 5×4.5 or 6×5.5 patterns depending on their load capacity and axle configuration. Boat trailers frequently employ 5×4.5 patterns, while larger utility trailers commonly use 6×5.5 configurations.

| Vehicle Type | Common Lug Patterns | Examples |

|---|---|---|

| Compact Cars | 4×100, 5×100 | Honda Civic, Toyota Corolla |

| Midsize Cars | 5×114.3, 4×108 | Honda Accord, Ford Fusion |

| Full-Size Cars | 5×114.3, 5×120 | Chevrolet Impala, BMW 3 Series |

| SUVs | 5×114.3, 6×139.7 | Toyota Highlander, Chevrolet Tahoe |

| Light Trucks | 6×139.7, 8×165.1 | Ford F-150, Chevrolet Silverado |

| Trailers | 5×4.5, 6×5.5 | Boat trailers, Utility trailers |

European vehicles often use metric measurements while American manufacturers typically employ imperial measurements for the same diameter. This variation means a 5×114.3 pattern (metric) equals a 5×4.5 pattern (imperial), representing the same bolt circle diameter expressed in different units.

Knowing these standard patterns allows us to verify our measurements and ensures we’re selecting compatible wheels for our exact vehicle type.

Reading and Understanding Your Measurements

Reading your rim lug pattern measurements requires understanding the standard format used in the automotive industry. We express lug patterns using two numbers separated by an “x” symbol, where the first number represents the quantity of lug holes and the second indicates the bolt circle diameter.

Standard Measurement Formats:

| Pattern Format | Example | Meaning |

|---|---|---|

| 4 x diameter | 4×100 | 4 lug holes, 100mm bolt circle |

| 5 x diameter | 5×114.3 | 5 lug holes, 114.3mm bolt circle |

| 6 x diameter | 6×139.7 | 6 lug holes, 139.7mm bolt circle |

| 8 x diameter | 8×165.1 | 8 lug holes, 165.1mm bolt circle |

Converting between metric and imperial measurements becomes necessary when working with different vehicle origins. European vehicles typically use metric measurements in millimeters, while American vehicles often reference imperial measurements in inches. We calculate conversions by multiplying millimeters by 0.0394 to get inches, or multiply inches by 25.4 to get millimeters.

Interpreting your measurement results requires comparing them to standard automotive specifications. Common bolt circle diameters include 100mm, 108mm, 112mm, 114.3mm, 120mm, 127mm, 139.7mm, and 165.1mm for metric patterns. Imperial patterns frequently measure 4.25″, 4.5″, 4.75″, 5″, 5.5″, 6″, and 6.5″ in diameter.

Verifying measurement accuracy involves cross referencing your results with vehicle manufacturer specifications. We recommend checking your vehicle’s owner manual, door jamb sticker, or online databases to confirm the correct lug pattern. Manufacturing tolerances typically allow for variations of ±1mm in bolt circle diameter measurements.

Documenting your measurements prevents future confusion when shopping for wheels or tires. Record both the lug count and bolt circle diameter in a format like “5×114.3mm” or “5×4.5″” depending on your preference. Keep this information with your vehicle documentation for easy reference during wheel purchases or maintenance visits.

Troubleshooting Common Measurement Mistakes

Measuring rim lug patterns incorrectly leads to expensive mistakes and potential safety hazards. We encounter several recurring errors when helping customers determine their wheel specifications.

Center-to-edge confusion with 5-lug patterns creates the most frequent measurement problem. Many people measure from the center of one lug hole to the center of the opposite lug hole when working with 5-lug wheels. This approach works perfectly for even-numbered patterns but fails with 5-lug configurations because no lug hole sits directly opposite another. We recommend measuring from the center of any lug hole to the outer edge of the second lug hole over for accurate 5-lug measurements.

Measuring lug hole diameter instead of bolt circle diameter represents another common error. The bolt circle diameter spans the distance between lug holes while lug hole diameter measures the individual opening size. We measure center-to-center distances between opposite lug holes for even patterns or center-to-outer-edge for 5-lug patterns to determine the correct bolt circle diameter.

Confusing backspacing measurements with bolt pattern specifications occurs frequently among first-time wheel buyers. Backspacing measures the distance from the wheel’s mounting surface to its inner edge while bolt pattern indicates lug hole spacing. We keep these measurements separate because they serve different fitment purposes and require distinct measurement techniques.

Using imprecise measuring tools compromises measurement accuracy and leads to incorrect specifications. Standard rulers lack the precision needed for exact bolt circle measurements particularly with 5-lug patterns. We use digital calipers or specialized bolt pattern gauges to achieve the accuracy required for proper wheel fitment.

Assuming all vehicles within a manufacturer use identical patterns creates compatibility issues. Different model years trim levels and engine configurations often feature varying lug patterns even within the same vehicle line. We verify measurements against manufacturer specifications rather than relying on assumptions about similar vehicles.

Converting between metric and imperial measurements incorrectly causes specification mismatches. European vehicles typically use millimeter measurements like 5×114.3mm while American vehicles reference inch measurements such as 5×4.5 inches. We double-check our conversions because 114.3mm equals 4.5 inches and mixing these units creates fitment problems.

Conclusion

Getting your rim lug pattern measurements right is crucial for both safety and your wallet. We’ve covered everything from basic counting techniques to precision measuring tools that’ll help you avoid costly mistakes.

Remember that different lug configurations require exact measurement approaches. Whether you’re dealing with a 4-lug pattern or an 8-lug setup each method we’ve outlined will give you the accuracy you need.

Take your time with these measurements and don’t hesitate to double-check your results. Using the right tools like digital calipers and cross-referencing with manufacturer specifications will save you from compatibility headaches down the road.

Now you’re equipped with the knowledge to confidently shop for new wheels knowing they’ll fit perfectly on your vehicle.

Frequently Asked Questions

What is a rim lug pattern and why is it important?

A rim lug pattern, also called a bolt pattern, refers to the arrangement of bolt holes that connect wheels to vehicle hubs. It’s defined by the number of bolt holes and the diameter of the circle formed by their centers. Getting the correct lug pattern is crucial for safety, proper fit, and vehicle stability. An incorrect pattern can lead to wheel detachment, compromised braking performance, and serious safety hazards.

How do I count the number of lug holes on my rim?

Visually count the lug holes around the center hub – they typically number 4, 5, 6, or 8 in a circular pattern. Count twice to ensure accuracy and mark each hole as you count to prevent confusion. You can also verify the count by checking your vehicle’s owner’s manual or manufacturer documentation for confirmation.

What tools do I need to measure my rim lug pattern accurately?

Essential tools include a ruler or measuring tape for basic measurements, digital calipers for enhanced precision, and a straightedge for alignment. Marking tools like pencils help identify lug hole centers. Professional mechanics often use specialized lug pattern gauges for the most accurate results. Having multiple measurement tools allows you to verify your results and minimize errors.

How do I measure a 4-lug or 6-lug pattern?

For both 4-lug and 6-lug patterns, measure the distance between two directly opposite lug holes (center to center). This measurement gives you the bolt circle diameter. Use precise measuring tools like digital calipers and double-check your measurements. Common 4-lug patterns include 4×100 and 4×114.3, while 6-lug patterns often measure 6×139.7 or 6×5.5.

How do I measure a 5-lug pattern?

For 5-lug patterns, you cannot measure directly opposite holes since there are an odd number. Instead, measure from the center of one lug hole to the outer edge of the farthest lug hole across from it. Use digital calipers for precision, as 5-lug measurements require more accuracy. Common 5-lug patterns include 5×114.3, 5×120, and 5×4.5.

How do I measure an 8-lug pattern?

For 8-lug patterns, measure the distance between two directly opposite lug holes, center to center. This gives you the bolt circle diameter. 8-lug patterns are typically found on heavy-duty trucks and large SUVs. Common sizes include 8×165.1 and 8×6.5. Always use precise measuring tools and consult your vehicle specifications for confirmation.

What are the most common lug patterns by vehicle type?

Compact and midsize cars typically use 4×100 or 5×114.3 patterns. Full-size cars and SUVs commonly feature 5×114.3 or 5×120 patterns. Light trucks and heavy SUVs often use 6×139.7 or 8×165.1 patterns. Trailers frequently employ 5×4.5 or 6×5.5 patterns. Understanding these standards helps verify your measurements and ensure compatibility.

How do I read lug pattern measurements?

Lug pattern measurements use a format with two numbers separated by an “x” symbol. The first number indicates the quantity of lug holes, and the second represents the bolt circle diameter. For example, “5×114.3” means 5 lug holes with a 114.3mm bolt circle diameter. European vehicles typically use millimeters, while American vehicles may reference inches.

What are common measurement mistakes to avoid?

Common errors include measuring from center to edge instead of center to center on 5-lug patterns, confusing lug hole diameter with bolt circle diameter, and incorrect metric-to-imperial conversions. Avoid assuming all vehicles from one manufacturer share the same pattern. Always use precise measuring tools like digital calipers and verify measurements against manufacturer specifications to prevent costly mistakes.

Should I convert between metric and imperial measurements?

Yes, conversion may be necessary since European vehicles typically use millimeters while American vehicles often reference inches. However, be extremely careful with conversions as small errors can lead to incompatible wheels. When possible, work with the original measurement system and verify your results against manufacturer specifications. Always double-check conversion calculations to ensure accuracy.