Ever found yourself puzzled by the flashing lights on your Hamm roller’s dashboard? You’re not alone. These warning lights, though small, play a crucial role in maintaining the health and longevity of your machine.

Understanding what these warning lights mean can be the difference between a minor repair and a major breakdown. Let’s unravel the mystery behind these symbols, helping you to keep your Hamm roller in top-notch condition.

Stay tuned as we decode the language of your Hamm roller’s warning lights. It’s time to turn that confusion into confidence, ensuring your roller runs smoothly and efficiently.

Understanding Hamm Roller Warning Lights

Integrating knowledge about Hamm Roller warning lights aids in implementing preventative maintenance. The following sections dissect the importance of these lights in heavy machinery operations and provide clarity about Hamm Rollers.

Importance of Warning Lights in Heavy Machinery

Recognizing warning lights in heavy machinery, such as Hamm Rollers, determines operational safety. For instance, an orange warning light signals maintenance, parts wear, or fuel issues. Conversely, red warning lights signal urgent situations, for example, an overheating engine. These visual cues make safety a foremost priority during your machinery operation, allowing for timely intervention and prevention of unnecessary downtime or costly repairs.

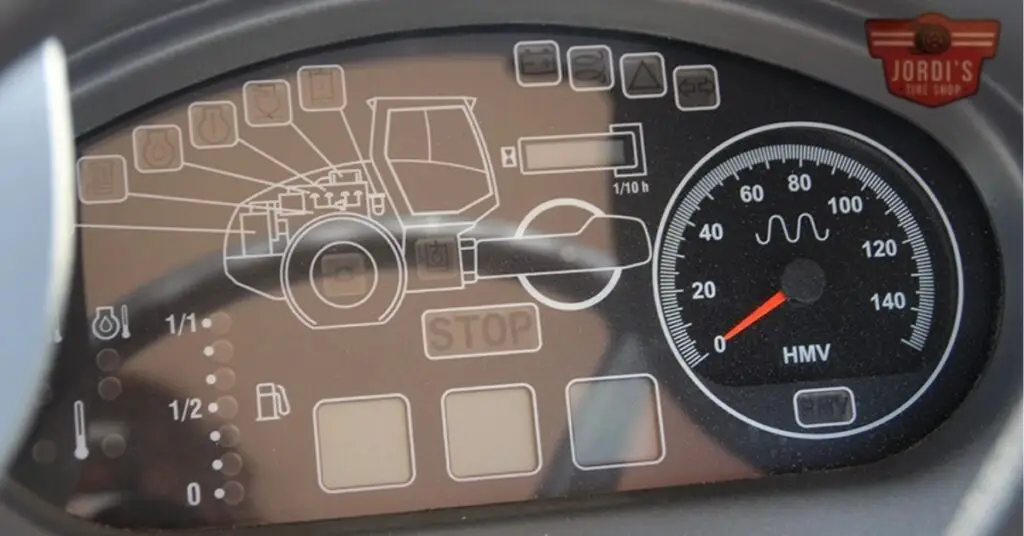

Brief Overview of Hamm Rollers

Hamm Rollers, part of the Wirtgen Group, have gained global renown for their quality and consistency in road construction since 1878. These heavy-duty machinery products personify excellence in the compaction of soil, gravel, and asphalt. Embedding features like the Hammtronic system, these machines provide user-friendly operation. This system regulates engine, travel drive, vibration, and oscillation, ensuring optimal responsiveness to varying construction conditions. Understanding your Hamm Roller’s warning lights is a prerequisite to harnessing its full potential.

Decoding the Hamm Roller Warning Lights

Diving deeper into the Hamm roller warning lights, let’s unlock their coded messages. You’ll find these signals critical for safety, performance optimization, and proactive maintenance.

Understanding Color Codes in Warning Lights

To begin, grasp the color codes in warning lights. In general, they come in three colors: amber, red, and green. For instance, amber lights communicate non-critical conditions, such as needing routine maintenance or minor issues. Red lights, on the other hand, highlight emergency conditions needing immediate attention. Green lights usually signal normal operations, implying everything’s functioning correctly.

The Meaning of Flashing and Steady Lights

Next up, it’s crucial to differentiate between flashing and steady lights. A flashing light typically suggests a non-critical issue that needs attention soon, while a steady light, irrespective of color, implies an urgent or severe condition requiring immediate intervention. By fully understanding these signals, you’ll be able to navigate through any maintenance needs or potential hiccups your Hamm roller might encounter. Remember, preventive action isn’t just about preserving your machine—it’s also about ensuring a safe work environment.

Common Hamm Roller Warning Lights and Their Meanings

Appreciating the essence of Hamm Roller warning lights aligns perfectly with machine preservation and creating a safe work environment. Let’s investigate into these key indicators, unraveling the significance behind each color – red, yellow, and green.

Red Warning Lights

In the area of Hamm Roller alert system, the red warning light bears much gravity. Its illumination signifies urgent attention, pointing towards a possible serious problem or malfunction with your machine. This instant alert implies conditions such as overheating, severe low oil pressure, or hydraulic system failure, among others. Such scenarios call for immediate action, halting machine operation and seeking professional help to prevent further damage.

Yellow Warning Lights

Next in line are the amber or yellow warning lights. Unlike their red counterparts, these don’t necessarily signal a life or death situation for your Hamm Roller. Instead, they are more of a cautionary sign, indicating non-critical conditions that require your attention. Even though not being immediately hazardous, disregarding these lights could escalate small issues over time. It’s a light that flags potential wear and tear, fuel problems, minor hydraulic system hitches, or engine service needs.

Green Warning Lights

Finally, you’ll encounter green warning lights on your Hamm Roller dashboard. In stark contrast with red and yellow, green signals indicate a condition of harmony – everything is in order. These lights often denote that the machine is performing optimally and all features are functioning as they should be. Nonetheless, while the green lights are a positive sign, it’s still imperative to maintain regular check-ups and maintenance tasks to keep your Hamm Roller running at its best.

Practical Tips on Responding to Warning Lights

To keep operations running smoothly and safely, responding promptly and correctly to your Hamm roller’s warning lights is crucial. Your actions can be crucial in preventing a minor problem from escalating into a substantial issue.

Immediate Steps to Take When a Warning Light Turns On

When a warning light illuminates, your initial response matters significantly. Start by stopping the roller to prevent any further potential damage that could be caused by continuing operation. Review the Hamm roller’s operator manual to identify the light’s meaning; doing so enables you to understand the exact issue you’re dealing with.

Upon identifying a light indicative of temperature issues, for instance, consider checking the engine coolant. If a hydraulic oil pressure light pops up, verify the hydraulic oil levels and look for possible leaks. When facing a light related to the battery or charging system, it’s worth inspecting your machine’s alternator and battery.

More importantly, don’t ignore flashing amber lights. Although not as critical as steady red lights, they signify attention-needed issues. Be proactive in addressing the indicated problems; this can save you from the possible downtime and costly repairs down the road.

When to Call for Professional Help

While there are issues you can tackle on your own, there are instances when professional assistance is necessary. Call for professional help when you encounter steady red warning lights, indicating severe issues. These can symbolize overheating, low oil pressure or charging system faults among others – conditions that warrant instant expert attention to prevent important damage.

Also, if a warning light stays on even though your efforts to resolve the issue, it’s advisable to call for professional assistance. Finally, if you’re unsure about anything related to the warning light, don’t hesitate to reach out to professionals. They have expansive knowledge and extensive experience dealing with Hamm rollers and can often offer the most efficient and effective answers.

Safety Precautions When Handling Hamm Rollers

Handling warning lights on Hamm Rollers promotes safety and performance. Follow this guide to understand regular maintenance actions and safety protocols in response to warning lights.

Regular Maintenance to Avoid Warning Light Issues

Preventive maintenance goes a long way in forestalling potential problems indicated by warning lights. Implementing regimen of regular checks aligns you with best practices for Hamm Roller operation. First, execute an engine oil check. A low oil level frequently triggers a red warning light. Second, review coolant levels. Inadequate coolant often results in an overheating warning symbol. Third, examine hydraulic systems. Faulty or low hydraulic fluid often illuminates a yellow warning sign.

Besides, ensure you carry out routine cleaning of your Hamm Roller’s air filters. This action minimizes the chances of triggering a sensor error warning light, indicating a blocked filter. Finally, don’t neglect the importance of inspecting the roller drum. Irregularities or abnormalities on its surface can also turn on the yellow warning light.

To maximize this routine, refer to your Hamm Roller’s operation manual, replenish depleted components, replace worn-out parts, and perform necessary adjustements based on recommended intervals.

Safety Protocols to Follow in Response to Warning Lights

Respecting the cues from warning lights is vital for your safety and the performance of your Hamm Roller. Upon detection of an illuminated warning light, immediately halt operations.

For amber warning lights, consult your operator manual to identify the source of the problem. If it’s flashing, it indicates a non-critical issue requiring soon attention. Address the issues promptly and responsibly, scrutinizing systems associated with the warning such as hydraulics or oil systems.

For a permanent red warning light, prioritize immediate check on major systems since it highlights a critical situation. In cases where the light remains on even though attempts to correct the issue, seek professional assistance.

While green lights indicate optimal machine operation, don’t let this color signal lull you into complacency. Continue regular maintenance checks to sustain good performance and forestall sudden breakdowns.

Eventually, clear knowledge and diligent response to warning lights on your Hamm Roller not only forestalls major machine problems but also ensures the safety and efficiency of your operations.

Conclusion

Now that you’re equipped with the knowledge about Hamm roller warning lights, you’re ready to tackle any light-related issues that may come your way. Remember, these lights are more than just indicators; they’re tools for effective machine operation and maintenance. Don’t underestimate the amber warning light – it’s a sign to act before a minor issue becomes a major problem. Red lights are your signal to stop and seek professional help. Green lights, while indicating everything is running smoothly, don’t mean you can skip regular maintenance. By responding proactively to these warning lights, you’ll ensure your Hamm roller stays in top shape, and you’ll foster a safer work environment. Keep learning, keep maintaining, and let those lights guide you to optimal Hamm roller operation.

What is the importance of Hamm roller’s dashboard warning lights?

The warning lights on a Hamm roller’s dashboard are critical in indicating the machine’s operational status. They help in proactive maintenance, signaling when minor repairs are needed or if a major breakdown is imminent. They also play a key role in safety and efficient performance optimization.

What do the different color warning lights indicate?

The color codes for the warning lights are: green for normal operations, amber for non-critical conditions that need attention, and red for emergencies that require immediate action.

How do flashing and steady lights differ in their meaning?

Flashing warning lights suggest non-critical issues requiring prompt attention, while steady lights signal urgent conditions that need immediate action.

What are Hamm Rollers and the Hammtronic system?

Hamm Rollers are recognized for their quality in road construction since 1878. The Hammtronic system in these rollers enhances user-friendly operation by regulating various machine functions.

What do red, yellow, and green warning lights signify on a Hamm Roller?

Red warning lights indicate serious problems requiring immediate attention. Yellow or amber warning lights caution about non-critical conditions that require attention, while green warning lights show the machine is operating optimally.

What are the recommended actions when a warning light turns on?

It’s crucial to stop the roller immediately when a warning light turns on. The specific issue should be identified by consulting the operator manual. Depending on the warning light, actions may include checking coolant levels or inspecting hydraulic oil.

When to seek professional help for warning lights?

Professional help should be sought for steady red warning lights that indicate severe problems. Also, if a warning light remains on despite attempts to address the issue, a professional should be consulted.

What are some essential maintenance actions for Hamm Rollers?

Essential maintenance actions include checking engine oil, coolant levels, hydraulic systems, clearing air filters, and inspecting the roller drum. Regular maintenance is crucial to prevent sudden machine breakdowns and to ensure safe, efficient operations.

What is the advisory in response to warning lights?

Upon detecting an illuminated warning light, it’s important to halt operations immediately. For amber lights, consultation of the manual is advised, while red lights require urgent checks of major systems. Apart from this, regular maintenance checks are also prescribed.

Related Posts:

- Exposed Cords on Tires: How Long Can They Last Before Replacement?

- Mastering the Art of Driving: Unraveling the Meaning of ‘Depress Brake Pedal’

- Solving the Mystery: Why Are Your Car’s Driver Information Center Buttons Not Working?

- Decoding Harley Davidson Dash Warning Lights: A Complete Guide for Safe Rides

- Unveiling the Mystery: Understanding Your Kioti Tractor Warning Lights

- Decoding Forklift Warning Light Symbols: A Comprehensive Guide to Ensuring Warehouse Safety

- Deciphering Hamm Roller Warning Lights: Your Guide to Safe & Efficient Operation

- Unlocking the Power of Jeep Compass Screen Lines: A Comprehensive Guide

- Steer Clear: Discover the Troublesome 7.3 Powerstroke Years to Avoid

- Unraveling the Mystery: What Causes Grooves in Your Car’s Brake Rotors?