Ever wondered what those flashing lights on your forklift mean? You’re not alone. Understanding forklift warning light symbols is crucial to ensure safety and efficiency in any warehouse or construction site.

These symbols aren’t just pretty lights; they’re your forklift’s way of communicating with you. It’s telling you something’s up, and you’d better pay attention. Let’s jump into the industry of forklift warning light symbols and unravel their meanings, shall we?

Remember, knowledge is power. And in this case, it could also mean preventing accidents and costly repairs. So, buckle up as we shed light on these often overlooked, yet vital aspects of forklift operation.

Understanding Forklift Warning Light Symbols

Forklift warning light symbols stand as an integral part of safety in any warehouse or construction site. They serve as silent yet loud communicators between the machinery and the operator. In this section, we dive deeper into the industry of these symbols, understanding their significances and meanings.

The Importance of Recognizing Warning Lights

Recognizing warning lights isn’t merely about knowing your machine. It’s about staying safe, keeping others safe, and ensuring the efficient operation of the forklift. Failure to recognize these lights can not only lead to minor inconveniences but can also potentially end in disastrous accidents or expensive repairs. So, understanding these light symbols isn’t a job exclusive to the operator; it’s a responsibility shared by everyone working in proximity to the forklift. Managers, supervisors, leads, and operators can all play a important role in fostering safer working environments by learning these symbols.

Decoding Common Forklift Light Symbols

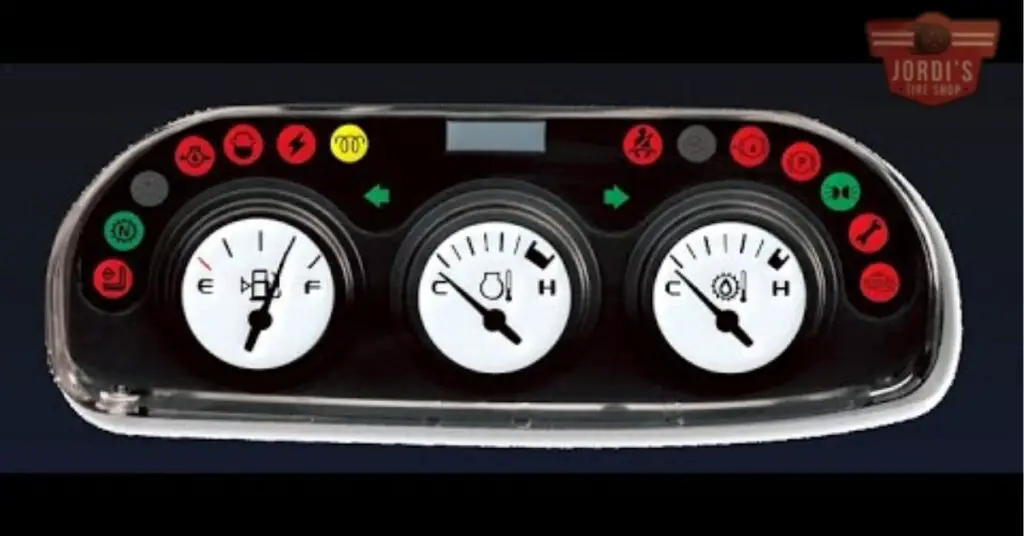

Several forklifts use universal symbols, which makes learning them a one-time investment. For instance, a battery-shaped symbol indicates a problem with the forklift’s battery, such as a low charge or a connectivity issue. Similarly, a thermos-shaped light signals a potential overheating problem. An oil can-shaped light, on the other hand, denotes issues with the oil levels or oil pressure. Conversely, some forklift brands can use distinct symbols. It’s prudent for you to familiarize yourself with the exact symbols and warnings of the equipment that you’ll be operating or working around. Always refer to the operator’s manual, which will provide in-depth information on the symbols and what actions to take if they light up.

The Role of Forklift Warning Lights in Workplace Safety

Addressing workplace safety, forklift warning lights play a pivotal part. They work as silent caretakers, informing of potential issues before escalating into hazards.

Preventing Accidents Through Light Signal Interpretation

By demystifying light signals, you cultivate a safer workspace. A flashing warning light doesn’t have to spell doom—it’s just the equipment voicing its needs. When a forklift’s warning light ignites, it’s crucial to promptly understand its symbol. Recognizing these symbols early on could be the difference between minor maintenance and a major accident. For instance, when a battery-shaped warning light illuminates, it indicates low battery power, highlighting the need to recharge it quickly to prevent forklift breakdown during operation.

Ensure to not only understand but respond appropriately to these signals. In case of a thermos-shaped light, signaling a potential overheating, halt the operation immediately. Cooling down before continuing operation prevents more severe machinery damage, mitigating risks of injuries, and minimizes downtime.

Improving Operational Efficiency with Warning Lights

Warning lights don’t just whistle-blow potential hazards, they also are invaluable tools in optimizing operational efficiency. Attending to early warnings saves costs by preventing possible intensive repairs. A faster response to a lit warning light minimizes disruption, aiding operational continuity, and through consequent maintenance practices, enhances longevity of forklifts.

Also, warning lights guide best practices in resource allocation. When a light illuminates, it’s your cue to schedule maintenance or replacements. By adhering to such signals, you avoid unexpected equipment shutdowns, so preserving the flow of your operations.

Forklift warning lights are assertive indicators that secure workplaces by preventing accidents and elevating operational efficiency. Wisdom lies in reading these signals in time and taking suitable action, confirming that a little knowledge can indeed prevent a big disaster.

Detailed Guide to Forklift Warning Light Symbols

Understanding forklift warning light symbols is integral in keeping a safe and efficient workspace. Considering your knowledge of their importance to workplace safety, let’s jump into more specifics.

Warning Light Symbols Related to Engine and Battery Issues

Know the forklift. One of the most common warning light symbols you’ll encounter relates to the engine and battery. An engine-shaped light typically signifies problems with the engine itself—typically demanding immediate inspection. Similarly, a battery-shaped light symbolizes battery issues. It’s an indication that your forklift’s battery charge is running low or experiencing other problems that could hamper the appliance’s performance.

Symbols Indicating Hydraulic and Brake System Problems

Be aware of the workings of the hydraulic and brake systems. A symbol resembling a teardrop or oil can isn’t to be ignored. This usually represents the hydraulic system, signifying a potential fluid leak or low fluid levels that compromise stability. A circle enclosed within brackets often signals brake system problems—a condition, lurking danger, mandating urgent attention to avoid mishaps.

Light Symbols for Transmission and Exhaust System Warnings

Navigate the mechanisms of transmission and exhaust systems. A light resembling a gear denotes issues with the transmission system which, left unattended, can impede your forklift’s operation efficiency. An exhaust pipe symbol, on the other hand, commonly signals problems with the exhaust system. It’s not an indicator to overlook; an improper exhaust system might lead to harmful emissions, posing important health risks to workers.

By understanding these light symbols, you’re promoting a safer and more efficient work environment. Emphasizing this knowledge ensures the safety and longevity of the forklifts, reigns in potential hazards, and contributes to operational efficiency.

Practical Tips for Reacting to Forklift Warning Lights

An understanding of forklift warning light symbols and the right actions to take upon their illumination can be a true lifesaver. Let’s investigate into the correct steps to adopt when a forklift warning light comes on and understand when it’s time to seek professional help for any forklift issues you may encounter.

Steps to Follow When a Warning Light Comes On

First off, do not panic. It’s vital to remain calm when a warning light gets illuminated, as panic can lead to accidents. Familiarize yourself with the operator’s manual, as different manufacturers may use various symbols. Always make it a point to conclusively identify the symbol that’s activated.

Following illumination, stop any operation you’re in the middle of, safely and systematically. Avoid abrupt moves that may result in accidents.

Next, check the operator’s manual for the illuminated symbol’s meaning. Manuals typically provide detailed information about the warning lights. Once you’ve pinpointed a problem, follow the instructions in the manual for initial safety measures.

Finally, should recommended actions fail to extinguish the light, immediately report the issue to your supervisor. Don’t attempt to carry on with the operation. Doing so can lead to further serious problems or even accidents.

When to Seek Professional Help for Forklift Issues

Getting professional help for forklift issues primarily depends on the severity of the issue and your ability to diagnose and address it. A simple example includes a low battery charge symbol, which requires the forklift to be charged. But, if repeatedly charging fails to resolve the problem, it’s time to engage a professional.

Software-related issues often necessitate professional assistance. Indicators for these include warning lights that keep flashing on and off and warning lights accompanied by odd forklift behavior, like unexplained slowing down or speeding up.

Professional help should also be sought whenever there are consistent hydraulic leaks or whenever you notice symptoms of a failing brake system, such as weakened braking power. Most transmission or exhaust system issues also demand professional attention due to their complexity.

Remember, captivating professionals for repair works not only enhances safety but also extends your forklift’s lifespan by ensuring issues are handled correctly and efficient answers are provided.

Tools to Assist with Forklift Warning Light Symbol Interpretation

Understanding forklift warning light symbols has been the core focus of the previous sections, offering insights into their interpretations and implications on safety and efficiency. To augment your knowledge, let’s further investigate into tools that can assist with the process.

Importance of Operator Manuals and Training

A crucial resource in interpreting forklift warning light symbols is the operator’s manual. Each forklift has its own unique set of symbols, contained within its respective manuals. Equating yourself with these symbols through systematic manual study aids in rapid and accurate symbol recognition.

Besides, operator training stands pivotal in the correct interpretation of these symbols. Formal training facilitates the learning of symbol meanings, troubleshooting procedures, and safety measures. An example of this can be the training programs conducted by the Occupational Safety and Health Administration (OSHA). OSHA stipulates training to be interactive and understandable to all employees, ensuring comprehensive learning of safety protocols including warning light symbols.

Technological Answers for Symbol Recognition

Plus to printed manuals and training, technology opens a new dimension in assisting with symbol recognition. Applications on smartphones, tablets, and computers can assist operators with real-time symbol interpretation. For instance, there are mobile applications available that function like a universal translator of warning light symbols for various machinery, including forklifts.

Machine Learning (ML) and Artificial Intelligence (AI) technologies can also play a part in symbol recognition. Some forklift models are equipped with monitors that display trouble codes corresponding to the lit up warning, offering additional information about potential issues.

Just as technology keeps progressing, so does the sophistication in aiding warning light symbol interpretation. Leveraging both traditional tools like manuals, training, and technological advancements can bolster overall safety and operational efficiency.

Conclusion

So you’ve seen how vital forklift warning light symbols are to maintaining safety and efficiency in your workspace. They’re more than just lights; they’re your forklift’s way of communicating potential issues that need your attention. It’s crucial for everyone, from operators to managers, to recognize these symbols and respond appropriately.

Remember, the key to preventing accidents and costly repairs lies in your understanding of these symbols. Don’t overlook the importance of your operator’s manual and formal training. They’re invaluable resources when it comes to decoding these symbols and knowing the necessary actions to take.

Also, technology is your ally in this try. With tools like mobile apps and AI, you can have real-time interpretations of warning lights at your fingertips. So keep learning, stay vigilant, and let these silent caretakers help you ensure a safer, more efficient working environment.

What is the importance of understanding forklift warning light symbols?

Understanding forklift warning light symbols is crucial as they serve as communication tools between the forklift and the operator. They alert operators about potential issues that require attention, preventing accidents and costly repairs. Familiarity with these symbols contributes to safety and efficiency in the workplace.

What might a battery-shaped and thermos-shaped light symbol indicate on a forklift?

A battery-shaped light symbol on a forklift usually indicates battery issues like low charge, while a thermos-shaped light signifies potential overheating. Both require immediate attention to prevent further machine damage and ensure operational safety.

How does recognizing warning lights contribute to operational efficiency?

Warning lights help minimize disruptions by prompting timely maintenance. Early recognition of these signals can differentiate between a minor maintenance issue and a major hazard. It enhances the longevity of forklifts, thereby improving operational efficiency.

What are the steps to take when a warning light on a forklift comes on?

The steps to take when a warning light illuminates include stopping operations safely, consulting the operator’s manual to identify the symbol, and reporting unresolved issues to a supervisor. Urgent and persistent problems, especially software-related issues, hydraulic leaks, and brake system failures, should be addressed by professionals.

Why are operator manuals and formal training important in understanding forklift warning light symbols?

Operator manuals contain a unique set of forklift warning light symbols and offer detailed guidance on responding to them. Meanwhile, formal training, like that provided by OSHA, provides operators with a deeper understanding of these symbols and safety protocols. Both resources are critical to maintaining safety and efficiency in the workplace.

How can new technology assist in interpreting forklift warning light symbols?

Advances in technology, including mobile applications and AI, can provide real-time interpretation of forklift warning lights. These tools supplement traditional resources like operator manuals, enhancing operators’ understanding and responsiveness to these signals, and thereby boosting work environment safety and efficiency.

Related Posts:

- Exposed Cords on Tires: How Long Can They Last Before Replacement?

- Mastering the Art of Driving: Unraveling the Meaning of ‘Depress Brake Pedal’

- Solving the Mystery: Why Are Your Car’s Driver Information Center Buttons Not Working?

- Decoding Harley Davidson Dash Warning Lights: A Complete Guide for Safe Rides

- Unveiling the Mystery: Understanding Your Kioti Tractor Warning Lights

- Decoding Forklift Warning Light Symbols: A Comprehensive Guide to Ensuring Warehouse Safety

- Deciphering Hamm Roller Warning Lights: Your Guide to Safe & Efficient Operation

- Unlocking the Power of Jeep Compass Screen Lines: A Comprehensive Guide

- Steer Clear: Discover the Troublesome 7.3 Powerstroke Years to Avoid

- Unraveling the Mystery: What Causes Grooves in Your Car’s Brake Rotors?