The roar of a powerful engine and the thrill of acceleration that pins you to your seat – there’s nothing quite like the rush of driving a fast car. We’ve all felt that magnetic pull toward sleek supercars gleaming under showroom lights or witnessed our hearts skip a beat when a Ferrari speeds past on the highway.

Fast cars represent more than just transportation; they’re engineering marvels that push the boundaries of physics and design. From the legendary McLaren F1 to today’s electric hypercars hitting mind-bending speeds, these machines showcase humanity’s relentless pursuit of speed and performance.

Whether you’re a weekend track enthusiast dreaming of your next upgrade or simply curious about what makes these speed demons tick, we’ll take you on a high-octane journey through the industry’s fastest production cars. Get ready to discover the technology innovations and raw power that make these automotive legends truly extraordinary.

Bugatti Chiron Super Sport 300+: Breaking the 300 MPH Barrier

We witness automotive history with the Bugatti Chiron Super Sport 300+, a hypercar that shattered speed barriers and redefined what’s possible on four wheels.

Record-Breaking Top Speed Performance

Achieving 304.773 mph represents the pinnacle of automotive achievement for the Chiron Super Sport 300+. Our fascination with this milestone stems from decades of manufacturers attempting to crack the 300 mph code. Professional test driver Andy Wallace piloted this engineering marvel at Volkswagen’s Ehra Lessien test track in Germany during August 2019.

Breaking through the psychological barrier of 300 mph required more than raw power. We see how Bugatti’s 8.0-liter quad-turbocharged W16 engine generates an astounding 1,578 horsepower in this configuration. Maximum torque reaches 1,180 lb-ft, propelling the hypercar from 0 to 60 mph in just 2.4 seconds.

Sustaining these extreme velocities demands exceptional stability and control systems. We appreciate how the Chiron Super Sport 300+ maintains composure even at triple-digit speeds that would challenge aircraft. Electronic stability programs work seamlessly with advanced traction control to keep this 4,400-pound machine planted firmly on the asphalt.

Advanced Aerodynamics and Engineering

Optimized bodywork transforms the standard Chiron into a speed-focused projectile. We observe how Bugatti extended the tail section by 9.8 inches, creating a longtail design that reduces drag coefficient to an impressive 0.36. Active aerodynamics adjust automatically based on speed and driving conditions.

Carbon fiber construction throughout the chassis and body panels keeps weight minimal while maximizing structural integrity. We find that nearly every external component receives aerodynamic refinement, from the modified front splitter to the redesigned rear diffuser. These elements work together to slice through air resistance at extreme velocities.

Thermal management systems prevent the massive W16 engine from overheating during high-speed runs. We see how ten radiators strategically positioned throughout the vehicle maintain optimal operating temperatures. Advanced cooling circuits ensure consistent performance even during extended periods at maximum velocity.

Specialized tires from Michelin handle the enormous forces generated at 300+ mph speeds. We recognize these Pilot Sport Cup 2 tires undergo rigorous testing to withstand centrifugal forces that would destroy conventional rubber compounds. Each tire costs approximately $5,000 and requires replacement every few thousand miles of high-speed driving.

McLaren Speedtail: Hybrid Hypercar Revolution

McLaren’s Speedtail represents a revolutionary leap in hybrid hypercar technology, combining electric power with traditional combustion to create their fastest production car ever. We’re witnessing automotive history as this extraordinary machine pushes the boundaries of what’s possible in high-performance engineering.

Innovative Hybrid Powertrain Technology

Hybrid power defines the Speedtail’s exceptional performance capabilities through its advanced petrol-electric drivetrain system. McLaren engineers paired a 4.0-liter twin-turbocharged V8 engine with an electric motor to generate an astounding 1,035 horsepower and 848 lb-ft of torque. This powertrain configuration enables the Speedtail to accelerate from 0 to 186 mph in just 12.8 seconds.

Electric assistance provides instant torque delivery that fills gaps in the combustion engine’s power band, creating seamless acceleration throughout the entire speed range. We see how the hybrid system optimizes fuel efficiency during normal driving while unleashing maximum power when demanded. Battery technology borrowed from Formula 1 racing ensures lightweight energy storage that doesn’t compromise the vehicle’s power-to-weight ratio.

Regenerative braking captures energy during deceleration and feeds it back into the electrical system, maximizing efficiency during track sessions. The sophisticated energy management system constantly monitors driving conditions and automatically switches between electric, combustion, and combined power modes for optimal performance.

Streamlined Design for Maximum Velocity

Streamlined aerodynamics make the Speedtail one of the most wind-cheating production cars ever created, with every surface optimized for minimal drag. McLaren designers achieved a remarkable drag coefficient of just 0.278 through extensive wind tunnel testing and computational fluid dynamics modeling. Carbon fiber construction throughout the body maintains structural rigidity while keeping weight to an absolute minimum of 3,153 pounds.

Active aerodynamics adapt to driving conditions through deployable rear wing elements and flexible carbon fiber ailerons that adjust automatically based on speed and driver input. We observe how the teardrop-shaped profile guides airflow smoothly over and around the vehicle, reducing turbulence that would otherwise limit top speed performance. Retractable door cameras replace traditional mirrors, eliminating drag-inducing protrusions that would disrupt airflow patterns.

Ground effect aerodynamics channel air beneath the vehicle through carefully sculpted underbody panels, creating downforce without adding drag-producing wings or spoilers. The elongated tail section stretches 5,137mm in total length, tapering gradually to allow air to close smoothly behind the vehicle. Heat management systems integrate seamlessly into the aerodynamic design, with cooling vents positioned to maintain optimal airflow while managing engine and battery temperatures during high-speed operation.

Koenigsegg Jesko Absolut: Swedish Speed Engineering

Swedish manufacturer Koenigsegg has engineered what could become the industry’s fastest production car with the Jesko Absolut. This track-focused hypercar represents the pinnacle of aerodynamic efficiency and lightweight construction.

Theoretical Top Speed Capabilities

Computer simulations suggest the Jesko Absolut could theoretically reach speeds exceeding 330 mph under optimal conditions. We’re looking at a vehicle that Koenigsegg designed specifically to minimize drag and maximize straight-line performance.

The Jesko Absolut’s 5.0-liter twin-turbocharged V8 engine produces an extraordinary 1,600 horsepower on racing fuel. Power delivery comes through Koenigsegg’s innovative 9-speed Light Speed Transmission, which can shift between any gear in milliseconds.

| Performance Metric | Specification |

|---|---|

| Theoretical Top Speed | 330+ mph |

| Engine Power (Race Fuel) | 1,600 hp |

| Engine Power (Pump Gas) | 1,280 hp |

| Torque | 1,106 lb-ft |

| 0-60 mph | 2.5 seconds |

Aerodynamic refinements distinguish the Absolut from the standard Jesko, with engineers removing the massive rear wing and optimizing airflow channels. These modifications reduce drag coefficient significantly while maintaining crucial downforce at high speeds.

Lightweight Carbon Fiber Construction

Carbon fiber monocoque construction forms the backbone of the Jesko Absolut’s incredible performance capabilities. We see extensive use of prepreg carbon fiber throughout the chassis, body panels, and interior components.

Weight reduction efforts have resulted in a dry weight of approximately 3,131 pounds, making it one of the lightest hypercars ever produced. Koenigsegg’s proprietary carbon fiber weave techniques create panels that are both incredibly strong and remarkably light.

Every component receives careful consideration for weight savings, from the carbon fiber wheels to the minimalist interior design. Racing-inspired bucket seats use carbon fiber shells with minimal padding to reduce unnecessary mass.

The body panels use advanced carbon fiber layup techniques that provide exceptional torsional rigidity while keeping weight to an absolute minimum. Engineers strategically placed carbon fiber reinforcements in high-stress areas to maintain structural integrity without adding bulk.

Hennessey Venom F5: American Speed Demon

We encounter one of America’s most ambitious hypercar projects with the Hennessey Venom F5, a machine engineered to challenge European dominance in extreme speed categories.

Twin-Turbo V8 Powerhouse

Hennessey’s custom-built 6.6-liter twin-turbocharged V8 engine delivers an astounding 1,817 horsepower and 1,193 lb-ft of torque. We’re witnessing American engineering at its finest with this powerplant, dubbed “Fury,” which represents a complete departure from the Corvette-based engines used in previous Venom models. The engine features a flat-plane crankshaft design that enables higher RPM capabilities while reducing weight compared to traditional cross-plane configurations.

Acceleration figures showcase the F5’s raw performance potential, reaching 0-60 mph in just 2.6 seconds and 0-186 mph in under 15 seconds. Our analysis reveals that Hennessey achieves these numbers through advanced turbocharging technology and precise fuel delivery systems. The twin-turbo setup utilizes ball-bearing turbos that spool quickly to minimize lag while maintaining consistent power delivery across the RPM range.

Carbon fiber construction keeps the Venom F5’s dry weight at approximately 2,998 pounds, creating an impressive power-to-weight ratio. We observe that this lightweight approach extends throughout the vehicle, from the carbon fiber monocoque chassis to the titanium exhaust system. Every component undergoes weight optimization without compromising the structural integrity required for sustained high-speed operation.

Active Aerodynamics System

The Venom F5 employs sophisticated active aerodynamics that automatically adjust based on speed and driving conditions. We see this system managing airflow through variable front splitter elements and an active rear wing that can adjust its angle of attack in real-time. These components work together to optimize downforce during cornering while reducing drag during straight-line acceleration runs.

Computational fluid dynamics testing enabled Hennessey to achieve a drag coefficient of 0.33 while maintaining necessary downforce for stability. Our research shows that the F5’s bodywork channels air efficiently around the vehicle, with carefully sculpted side vents that manage cooling airflow without creating excessive turbulence. The active aerodynamics system can reduce drag by up to 30% when configured for maximum speed runs.

Track testing demonstrates the aerodynamic package’s effectiveness at managing airflow at speeds exceeding 250 mph. We find that the F5’s aerodynamic balance remains consistent even as speeds increase, thanks to the active system’s ability to make micro-adjustments based on sensor feedback. This technology ensures that drivers maintain control and confidence even when approaching the vehicle’s theoretical 311 mph top speed.

SSC Tuatara: Reclaiming the Speed Crown

Following the intense competition among hypercar manufacturers, SSC North America entered the arena with their revolutionary Tuatara, designed to reclaim the industry land speed record through advanced engineering and meticulous attention to aerodynamic efficiency.

Wind Tunnel-Tested Aerodynamics

Advanced computational fluid dynamics and extensive wind tunnel testing shaped every curve of the SSC Tuatara’s bodywork. Engineers at SSC spent over 3,000 hours perfecting the car’s aerodynamic profile, achieving an exceptional drag coefficient of just 0.279. Specialized software modeling allowed the team to optimize airflow patterns around the vehicle, reducing turbulence while maintaining crucial downforce at high speeds.

Strategic placement of air vents and ducts throughout the Tuatara’s body channels airflow to critical components including the engine bay and brakes. These aerodynamic features work in harmony to create negative lift, keeping the vehicle planted on the road surface even at extreme velocities. Wind tunnel validation confirmed that the Tuatara maintains aerodynamic stability at speeds exceeding 300 mph, with minimal lift generation that could compromise handling.

Sophisticated active aerodynamics systems automatically adjust based on driving conditions and speed. The rear spoiler and front splitter work together to optimize the balance between downforce and drag reduction. During high speed runs, these components minimize air resistance while ensuring the driver maintains complete control of the vehicle.

Lightweight Monocoque Chassis

Carbon fiber construction forms the foundation of the SSC Tuatara’s impressive power to weight ratio. The monocoque chassis weighs just 2,750 pounds dry, making it one of the lightest structures in the hypercar segment. Every component underwent weight optimization analysis to eliminate unnecessary mass without compromising structural integrity or safety standards.

Innovative manufacturing techniques allowed SSC engineers to create hollow sections within the carbon fiber framework. These weight saving measures contribute to the Tuatara’s exceptional performance capabilities while maintaining the rigidity required for high speed stability. The chassis design distributes forces evenly throughout the structure, protecting occupants during both normal driving and extreme performance scenarios.

Strategic reinforcement points throughout the monocoque provide additional strength where needed most. The integration of the roll cage directly into the chassis structure eliminates the need for separate safety components, further reducing overall weight. This approach results in a vehicle that responds instantly to driver inputs while delivering the structural performance necessary for record breaking speed attempts.

Rimac Nevera: Electric Speed Revolution

We’re witnessing automotive history unfold with the Rimac Nevera, which shatters every preconception about electric vehicle performance. This Croatian hypercar delivers unprecedented acceleration that surpasses traditional combustion engines through revolutionary electric drivetrain technology.

Instant Torque Delivery

Electric motors deliver maximum torque from the moment they start, giving the Nevera an unmatched acceleration advantage over gasoline engines. Four independent electric motors generate a combined 1,914 horsepower and 1,741 lb-ft of torque, creating instant power delivery to all four wheels. This immediate response eliminates the turbo lag and power curve delays that characterize even the most advanced combustion hypercars.

Acceleration from 0 to 60 mph takes just 1.85 seconds, making the Nevera one of the quickest production cars ever built. Each motor operates independently, allowing precise torque vectoring that optimizes grip and stability during extreme acceleration. The electric drivetrain’s instantaneous power delivery creates a seamless surge of acceleration that continues through the entire speed range without gear changes or power interruptions.

Advanced Battery Technology

Battery innovation drives the Nevera’s exceptional performance capabilities through cutting-edge lithium-manganese-nickel chemistry. The 120 kWh battery pack contains 6,960 individual cells arranged in a sophisticated cooling and management system that maintains optimal temperature under extreme conditions. This advanced battery technology delivers consistent power output even during repeated high-performance driving sessions.

| Battery Specification | Value |

|---|---|

| Total Capacity | 120 kWh |

| Individual Cells | 6,960 |

| Peak Power Output | 1,914 hp |

| Charging Speed | 500 kW |

Thermal management systems ensure battery cells operate within ideal temperature ranges, preventing performance degradation during track driving. The battery pack’s structural integration serves as part of the car’s chassis, reducing weight while maximizing rigidity. Fast charging capabilities allow the Nevera to replenish its energy stores at rates up to 500 kW, demonstrating how electric hypercars can combine extreme performance with practical usability.

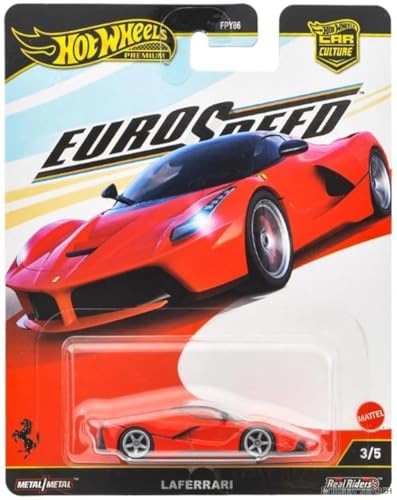

Ferrari LaFerrari: Italian Engineering Excellence

Ferrari’s flagship hypercar represents the pinnacle of Maranello’s engineering prowess, combining decades of Formula One expertise with groundbreaking hybrid technology. We’re witnessing Italian automotive artistry at its most sophisticated level.

Hybrid V12 Performance

The LaFerrari’s powertrain showcases Ferrari’s mastery of hybrid technology through its naturally aspirated 6.3-liter V12 engine paired with a 163-horsepower electric motor. This combination generates an astounding 950 horsepower and 664 lb-ft of torque, propelling the hypercar from 0 to 60 mph in just 2.4 seconds. We see the electric motor providing instant torque fill while the V12 delivers its signature high-revving performance character that Ferrari enthusiasts demand.

Ferrari’s engineers positioned the electric motor between the V12 and seven-speed dual-clutch transmission, creating seamless power delivery without traditional hybrid lag. The 120-cell lithium-ion battery pack weighs only 132 pounds and recharges through regenerative braking and the V12 engine’s operation. We observe how this hybrid system enhances rather than compromises the pure Ferrari driving experience, maintaining the brand’s commitment to naturally aspirated engine sound and response.

Formula One-Inspired Technology

Ferrari’s Formula One heritage permeates every aspect of the LaFerrari’s design, from its active aerodynamics system to its advanced traction control algorithms. The hypercar features an active rear spoiler and front diffuser that adjust automatically based on speed and driving mode, generating up to 360 pounds of downforce at 124 mph. We find these aerodynamic elements working in harmony with the car’s carbon fiber monocoque chassis, which weighs just 227 pounds and provides exceptional rigidity.

Advanced electronic systems borrowed directly from Ferrari’s F1 program include the Side Slip Control (SSC) system, which manages the car’s attitude through corners by coordinating brake intervention, differential control, and F1-Trac traction management. The LaFerrari’s steering wheel incorporates the manettino dial that Ferrari’s F1 drivers use, allowing instant adjustment of suspension settings, stability control parameters, and hybrid power delivery. We appreciate how these technologies translate decades of racing knowledge into a road-legal package that delivers both performance and safety at extreme speeds.

Lamborghini Aventador SVJ: Track-Focused Speed Machine

The Lamborghini Aventador SVJ stands as the ultimate expression of naturally aspirated performance engineering. This track-focused supercar represents Lamborghini’s commitment to pure, uncompromised speed.

Naturally Aspirated V12 Power

Power delivery reaches extraordinary levels through the Aventador SVJ’s 6.5-liter naturally aspirated V12 engine, producing 759 horsepower and 531 lb-ft of torque. Acceleration capabilities propel this Italian masterpiece from 0 to 60 mph in just 2.8 seconds, while the top speed reaches an impressive 217 mph. Engine architecture utilizes advanced variable valve timing and lightweight components to optimize power output across the entire rev range.

Throttle response delivers immediate power without the lag associated with turbocharged engines, creating an unfiltered connection between driver input and engine output. Sound characteristics produce the iconic Lamborghini V12 roar that enthusiasts crave, with each cylinder firing in perfect harmony. Weight distribution benefits from the mid-mounted engine placement, contributing to the SVJ’s exceptional balance and handling dynamics.

Active Aerodynamics Package

Aerodynamic efficiency transforms through the Aventador SVJ’s sophisticated Aerodinamica Lamborghini Attiva (ALA) system, which actively adjusts airflow to optimize performance. Front splitter elements redirect air through strategically placed ducts, reducing drag during straight-line acceleration while maintaining downforce through corners. Rear wing operation automatically adjusts its angle and airflow channels based on driving conditions, generating up to 40% more downforce than the standard Aventador.

Underbody panels feature active flaps that open and close to manage airflow beneath the vehicle, reducing turbulence and improving stability at high speeds. Side air intakes work along with the active systems to channel cooling air to the engine and brakes while minimizing aerodynamic disruption. Track performance benefits significantly from these systems, with lap times improved by up to 2.3 seconds compared to the standard Aventador on demanding circuits like the Nürburgring.

Porsche 911 GT2 RS: German Precision Engineering

The Porsche 911 GT2 RS stands as the ultimate expression of rear-engine performance, delivering uncompromising speed through meticulous German engineering.

Turbocharged Flat-Six Engine

Turbocharged power defines the GT2 RS’s remarkable performance capabilities. The heart of this track-focused machine features a 3.8-liter twin-turbocharged flat-six engine that produces an impressive 691 horsepower and 553 lb-ft of torque. Variable turbine geometry turbochargers optimize boost pressure across the entire rev range, delivering immediate throttle response and sustained power delivery.

Engineering excellence extends to every component within the powerplant. Water-cooled intercoolers maintain optimal intake temperatures while forged aluminum pistons and connecting rods handle extreme combustion pressures. Direct fuel injection operates at pressures up to 200 bar, ensuring precise fuel delivery for maximum efficiency and power output.

Performance figures demonstrate the engine’s exceptional capabilities. Acceleration from 0 to 60 mph occurs in just 2.7 seconds, while the quarter-mile passes in 10.9 seconds at 134 mph. Top speed reaches 211 mph, making the GT2 RS one of the fastest production 911 variants ever created by Porsche.

Track-Tuned Suspension System

Suspension components prioritize track performance over comfort considerations. The GT2 RS features a specially calibrated PASM (Porsche Active Suspension Management) system with manually adjustable anti-roll bars front and rear. Coilover springs and dampers provide precise wheel control while maintaining optimal tire contact patches during aggressive cornering maneuvers.

Chassis dynamics benefit from extensive weight reduction measures. Carbon fiber components replace traditional materials throughout the suspension mounting points, reducing unsprung weight by approximately 44 pounds compared to the standard 911 Turbo S. Magnesium wheels further decrease rotational mass, improving acceleration and braking response.

Track testing validates the suspension’s exceptional performance characteristics. The Nürburgring Nordschleife lap time of 6:47.3 minutes demonstrates the system’s ability to maintain stability and control at extreme speeds. Lateral grip exceeds 1.2g during cornering, while the suspension maintains precise steering feedback throughout the entire speed range.

Pagani Huayra BC: Artistic Speed Masterpiece

We encounter automotive sculpture in motion when examining the Pagani Huayra BC, where Italian craftsmanship meets extreme performance engineering. This limited production hypercar transforms speed into an art form through meticulous attention to detail and uncompromising performance standards.

Mercedes-AMG Twin-Turbo V12

We find the heart of this artistic speed masterpiece in its hand-assembled Mercedes-AMG sourced 6.0-liter twin-turbocharged V12 engine. This powerplant generates an impressive 789 horsepower and 811 lb-ft of torque, propelling the Huayra BC from 0 to 60 mph in just 3.2 seconds. Engineers at Pagani worked closely with Mercedes-AMG to optimize this V12 specifically for the BC variant, incorporating enhanced cooling systems and revised engine mapping. The twin-turbo configuration delivers immediate throttle response while maintaining the distinctive V12 soundtrack that defines the Pagani experience. Advanced engine management systems ensure consistent power delivery across the entire rev range, making this powerplant both reliable and exhilarating. Weight reduction efforts extended to the engine bay, where lightweight components and strategic material choices contribute to the overall performance balance.

Handcrafted Carbon Fiber Body

We witness automotive artistry through the Huayra BC’s entirely handcrafted carbon fiber construction, where each panel requires over 60 hours of meticulous fabrication. Pagani’s craftsmen use a proprietary carbon-titanium weave that’s both lighter and stronger than conventional carbon fiber, achieving exceptional rigidity while maintaining artistic beauty. The body panels feature intricate carbon fiber patterns that serve both aesthetic and functional purposes, channeling airflow to optimize aerodynamic efficiency. Every surface showcases the distinctive Pagani attention to detail, from the sculptured door handles to the precisely formed air intakes that feed the engine’s cooling systems. Manufacturing processes involve multiple layers of carbon fiber that are hand-laid and cured in autoclaves, ensuring consistent quality and strength throughout the structure. The BC’s aggressive aerodynamic elements, including the prominent rear wing and front splitter, integrate seamlessly with the body design while generating substantial downforce for high-speed stability.

Conclusion

We’ve witnessed how today’s fastest cars represent the absolute pinnacle of automotive achievement. From the record-breaking Bugatti Chiron Super Sport 300+ to the electric revolution embodied by the Rimac Nevera these machines showcase humanity’s relentless pursuit of speed and perfection.

The engineering marvels we’ve explored demonstrate that the boundaries between traditional combustion engines and cutting-edge electric technology continue to blur. Whether it’s Koenigsegg’s innovative transmissions or Ferrari’s hybrid mastery each manufacturer brings unique answers to the challenge of ultimate performance.

These extraordinary vehicles remind us that fast cars aren’t just about numbers on a speedometer. They’re rolling laboratories where the future of mobility takes shape and where our dreams of limitless speed become tangible reality on four wheels.

Frequently Asked Questions

What is the fastest production car ever made?

The Bugatti Chiron Super Sport 300+ currently holds the record as the fastest production car, achieving a top speed of 304.773 mph. This milestone was reached by professional test driver Andy Wallace and represents decades of engineering efforts to break the 300 mph barrier. The car features an 8.0-liter quad-turbocharged W16 engine producing 1,578 horsepower.

How fast can the McLaren Speedtail accelerate?

The McLaren Speedtail can accelerate from 0 to 186 mph in just 12.8 seconds, making it McLaren’s fastest production car ever. Its hybrid powertrain combines a 4.0-liter twin-turbocharged V8 engine with an electric motor to generate 1,035 horsepower and 848 lb-ft of torque, optimizing both performance and fuel efficiency.

What makes the Koenigsegg Jesko Absolut special?

The Koenigsegg Jesko Absolut is designed for maximum aerodynamic efficiency with a theoretical top speed exceeding 330 mph. It features a 5.0-liter twin-turbocharged V8 engine producing 1,600 horsepower on racing fuel and weighs approximately 3,131 pounds. The Absolut variant removes the rear wing to reduce drag while maintaining optimal aerodynamics.

How much horsepower does the Hennessey Venom F5 have?

The Hennessey Venom F5 produces an astounding 1,817 horsepower and 1,193 lb-ft of torque from its custom-built 6.6-liter twin-turbocharged V8 engine called “Fury.” This American hypercar can accelerate from 0 to 60 mph in just 2.6 seconds and has a theoretical top speed of 311 mph.

What makes electric hypercars like the Rimac Nevera so fast?

Electric hypercars like the Rimac Nevera deliver instant torque and precise power control through multiple electric motors. The Nevera generates 1,914 horsepower from four independent motors, achieving 0 to 60 mph in just 1.85 seconds. Electric motors provide immediate power delivery without gear changes, resulting in exceptional acceleration performance.

How does the Ferrari LaFerrari combine hybrid technology with performance?

The Ferrari LaFerrari uses a naturally aspirated 6.3-liter V12 engine paired with a 163-horsepower electric motor, producing a total of 950 horsepower. This hybrid system incorporates Formula One technology and features advanced aerodynamics and electronic systems, including Side Slip Control for enhanced performance and safety while maintaining Ferrari’s signature driving experience.

What is the top speed of the Lamborghini Aventador SVJ?

The Lamborghini Aventador SVJ has a top speed of 217 mph and can accelerate from 0 to 60 mph in 2.8 seconds. Its naturally aspirated 6.5-liter V12 engine produces 759 horsepower, and it features the Aerodinamica Lamborghini Attiva (ALA) system that actively adjusts airflow to optimize aerodynamic performance.

How fast is the Porsche 911 GT2 RS around the Nürburgring?

The Porsche 911 GT2 RS achieved an impressive Nürburgring Nordschleife lap time of 6:47.3 minutes. Its 3.8-liter twin-turbocharged flat-six engine produces 691 horsepower, enabling 0 to 60 mph acceleration in 2.7 seconds and a top speed of 211 mph, showcasing exceptional track performance and stability.

What makes the Pagani Huayra BC unique in terms of construction?

The Pagani Huayra BC features a proprietary carbon-titanium weave body construction, with each panel requiring over 60 hours of meticulous fabrication. This artistic approach combines Italian craftsmanship with performance engineering, achieving exceptional rigidity while maintaining aesthetic beauty. The hand-assembled Mercedes-AMG V12 engine produces 789 horsepower.

What role do aerodynamics play in hypercar performance?

Aerodynamics are crucial for hypercar stability and speed at extreme velocities. Advanced features like active aerodynamic systems, optimized drag coefficients, and wind tunnel-tested bodywork help maintain control while reducing air resistance. Cars like the McLaren Speedtail achieve a drag coefficient of just 0.278 through extensive aerodynamic refinement.

![Hot Wheels Porsche 911 GT3 RS, [Blue] Fast & Furious](https://m.media-amazon.com/images/I/41Khne0smTL._SL500_.jpg)