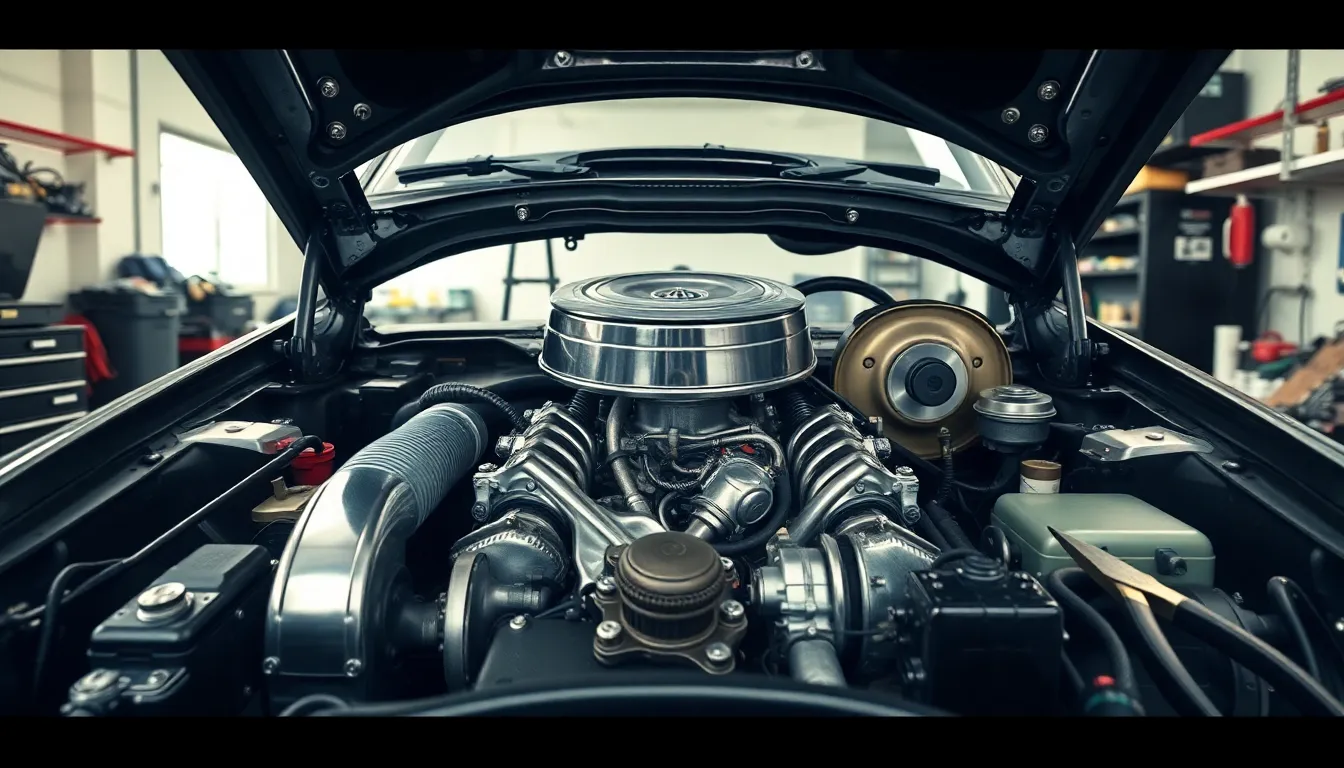

Your car’s engine works tirelessly under the hood while collecting dirt grease and grime that can seriously impact its performance and longevity. We’ve all heard that keeping our cars clean matters but most of us forget about what’s happening beneath the surface where it counts most.

Engine washing isn’t just about aesthetics – it’s a crucial maintenance practice that can extend your vehicle’s life save you thousands in repairs and boost your engine’s efficiency. When debris accumulates on engine components it creates heat retention issues corrodes vital parts and makes it nearly impossible to spot potential problems before they become expensive disasters.

We’ll show you exactly how to safely clean your engine bay like a pro including the tools you’ll need step-by-step techniques and common mistakes that could damage your vehicle. Whether you’re a DIY enthusiast or just want to understand what your mechanic should be doing proper engine washing is easier than you think.

What Is Engine Wash and Why It Matters

Engine wash refers to the systematic cleaning process that removes dirt, grease, grime, and debris from the engine bay and external engine components. This maintenance practice involves using specialized cleaning products, water, and proper techniques to restore the engine compartment’s appearance while preserving the integrity of sensitive electrical components.

Modern vehicles accumulate various contaminants in their engine bays through normal operation. Road salt, oil leaks, dust particles, and automotive fluids create a layer of buildup that affects both performance and visual appeal. Engine washing addresses these accumulations through targeted cleaning methods that reach areas traditional car washing cannot access.

Primary benefits of regular engine washing include:

- Enhanced heat dissipation from engine components

- Improved visibility for maintenance inspections

- Prevention of corrosive damage to metal surfaces

- Extended lifespan of rubber hoses and seals

- Easier identification of fluid leaks and mechanical issues

Performance improvements occur when clean engine surfaces dissipate heat more effectively than dirty ones. Studies show that excessive dirt buildup can increase operating temperatures by 15-20 degrees Fahrenheit, potentially leading to premature component failure. Clean engines also allow mechanics and vehicle owners to spot problems during routine inspections more easily.

Key engine wash applications cover these vehicle types:

| Vehicle Category | Wash Frequency | Primary Benefits |

|---|---|---|

| Daily drivers | Every 6 months | Leak detection, heat management |

| Performance vehicles | Every 3 months | Optimal cooling, component visibility |

| Off-road vehicles | Monthly | Debris removal, corrosion prevention |

| Classic cars | Seasonally | Preservation, show preparation |

Neglecting engine cleaning creates cascading maintenance issues that cost significantly more than preventive washing. Accumulated grime traps moisture against metal surfaces, accelerating rust formation and component degradation. Professional mechanics report that clean engine bays reduce diagnostic time by up to 40% during service appointments.

Environmental factors determine the frequency and intensity of engine washing requirements. Vehicles operated in coastal areas face salt corrosion challenges, while those in dusty climates deal with abrasive particle accumulation. Urban driving exposes engines to oil residue and chemical pollutants that require specialized cleaning approaches.

Types of Engine Wash Products

Engine wash products come in three main categories that target different cleaning challenges and material compatibility requirements. Each type offers distinct advantages for maintaining your engine bay’s cleanliness and performance.

Foam-Based Engine Cleaners

Foam-based cleaners create thick foam that clings to vertical and horizontal engine surfaces, providing extended contact time for effective dirt removal. The foam penetrates hard-to-reach areas without requiring excessive scrubbing or disassembly of engine components. Gunk Foam Engine Bright exemplifies this category by using foaming action to lift dirt and grime quickly while remaining safe on plastics and painted surfaces. These cleaners work particularly well on engines with moderate dirt buildup and offer excellent coverage across complex engine geometries.

Spray-On Degreasers

Spray-on degreasers deliver concentrated cleaning power through liquid answers that emulsify oil and stubborn grease deposits. These products vary significantly in chemical strength, with industrial-grade formulations like CRC Pro-Strength Degreaser tackling heavy contamination and gentler versions like Gunk Original protecting delicate engine components. Direct application allows precise targeting of exact problem areas, though thorough rinsing becomes essential to prevent residue buildup on sensitive parts. Professional mechanics often prefer spray-on degreasers for their versatility and immediate cleaning action on heavily soiled engines.

Water-Based Answers

Water-based engine washes combine cleaning agents with water to reduce toxicity while maintaining effective degreasing capabilities. These formulations prove gentler on aluminum components, rubber seals, and painted surfaces compared to solvent-based alternatives. Environmental impact remains minimal with water-based answers, making them suitable for frequent maintenance cleaning without regulatory concerns. Application involves spraying the solution, allowing brief reaction time, and rinsing with water to complete the cleaning process.

Best Engine Wash Products on the Market

We’ve tested and evaluated many engine cleaning products to identify the most effective options for different budgets and cleaning requirements. Our analysis reveals clear distinctions between premium formulations and cost-effective alternatives that deliver exceptional results.

Top Premium Options

Chemical Guys Signature Series Orange Degreaser leads our premium category with its environmentally friendly formulation and VOC regulation compliance. Professional detailers consistently rate this product for its effective cleaning power while maintaining safety around sensitive automotive surfaces.

Gunk Original Engine Brite delivers exceptional cleaning performance with its ability to restore engine bay shine. This product excels at rejuvenating engine components and removing heavy grease accumulation that builds up over time.

WD-40 Specialist Machine & Engine Degreaser Foaming Spray provides superior penetration through its foaming action technology. The foam formulation reaches difficult areas where traditional sprays fail, while maintaining an accessible price point within the premium segment.

Meier’s Super Degreaser offers heavy-duty performance across multiple vehicle types including cars, trucks, and boats. We recommend this product for users requiring versatile cleaning power across different engine configurations.

Budget-Friendly Alternatives

Motor Medic Heavy Duty Engine Degreaser delivers cleaning results comparable to premium brands at significantly lower costs. Testing shows this product performs effectively on aluminum, rubber, and painted surfaces without causing material damage.

CRC Pro-Strength Engine Degreaser provides thorough cleaning performance while maintaining material safety across various engine components. The accessible pricing makes this option attractive for regular maintenance schedules.

LA’s Totally Awesome serves as an effective alternative even though its primary concrete cleaning marketing. Users report strong engine cleaning performance at substantially lower costs compared to automotive-exact products.

Simple Green Pro HD functions as a versatile cleaning solution that performs well for engine washing applications. Budget-conscious consumers favor this product for its multi-purpose capabilities and consistent cleaning results.

How to Properly Wash Your Engine

Engine washing requires systematic preparation and careful execution to achieve optimal results without damaging sensitive components. Following these proven techniques ensures effective cleaning while protecting your vehicle’s electrical systems and delicate parts.

Preparation Steps

Disconnect the car battery before beginning any cleaning process to prevent electrical shocks and component damage. This critical safety measure protects both you and your vehicle’s electronic systems during the washing procedure.

Remove covers and protect sensitive components using plastic wrap or aluminum foil around electrical connections and sensors. Focus particularly on covering the alternator, fuse box, and air intake system to prevent water infiltration.

Wait for the engine to cool down completely before applying any cleaning products or water. Hot engine surfaces can cause rapid evaporation of cleaning answers and create dangerous steam that may result in burns.

Document the engine bay layout by taking photographs before starting the cleaning process. These reference images help ensure proper reassembly and component placement after washing.

Application Process

Remove loose debris using a soft bristled brush or compressed air to clear dirt and accumulated particles from accessible surfaces. Target areas around the battery terminals, air filter housing, and fluid reservoirs where debris commonly accumulates.

Apply an engine safe degreaser evenly across all surfaces, avoiding foaming formulations that can cause corrosion if not thoroughly rinsed. Allow the degreaser to penetrate for the manufacturer’s recommended contact time before proceeding.

Rinse with low pressure water using a standard garden hose rather than high pressure washers that can force moisture into electrical components. Direct the water flow away from sensitive areas while ensuring complete degreaser removal.

Dry the engine bay thoroughly with microfiber cloths and compressed air to eliminate residual moisture from crevices and electrical connections. Pay special attention to areas around spark plug wells and connector housings.

Apply protective dressing to rubber hoses and plastic surfaces after complete drying to prevent aging and cracking. This final step maintains component flexibility and appearance between washing cycles.

Safety Precautions

Wear protective gear including chemical resistant gloves and safety glasses throughout the entire washing process. These items protect against splashing cleaning products and debris displacement during scrubbing activities.

Avoid sensitive electrical components such as the alternator, battery terminals, and electronic control modules during direct water application. Create barriers around these areas or clean them separately with appropriate electrical contact cleaners.

Use soft bristled brushes for stubborn stain removal rather than abrasive materials that can scratch plastic surfaces or damage component labels. Gentle scrubbing techniques prove more effective than aggressive mechanical action.

Ensure adequate ventilation when working with chemical degreasers in enclosed spaces like garages. Proper airflow prevents vapor concentration and reduces inhalation risks during extended cleaning sessions.

Benefits of Regular Engine Washing

Regular engine washing transforms vehicle maintenance by delivering measurable improvements across multiple performance areas. Cleaning removes accumulated debris such as dirt, dust, and oil that clogs airflow within the engine bay. This buildup forces engines to work harder and reduces overall efficiency.

Improved Engine Performance and Efficiency

Clean engines operate more smoothly and deliver better fuel efficiency compared to neglected counterparts. Optimal airflow allows engines to cool themselves effectively, preventing overheating and related damage. Performance gains become noticeable when contaminants no longer interfere with critical engine components.

| Performance Metric | Clean Engine | Dirty Engine |

|---|---|---|

| Fuel Efficiency | Optimal | Reduced by 5-10% |

| Operating Temperature | Normal Range | Elevated |

| Airflow | Unrestricted | Partially Blocked |

Enhanced Safety and Reduced Risk

Engine bay cleanliness helps identify leaks and mechanical issues before they escalate into major repairs. Oil and coolant leaks become visible early when grime doesn’t obscure critical areas. Fire hazards decrease significantly when flammable materials like oil and grease get removed regularly.

Electrical malfunctions occur less frequently in clean engine bays where dirt and debris can’t interfere with connections. We observe fewer electrical issues in vehicles that receive consistent engine cleaning compared to those that don’t.

Extended Engine Lifespan

Corrosion and rust prevention represents another key advantage of regular engine washing. Contaminants accelerate component degradation when left unchecked over extended periods. Sensitive parts receive protection through consistent cleaning practices that remove corrosive substances.

Engine components maintain their integrity longer when exposed to fewer harmful contaminants. Metal surfaces resist deterioration more effectively in clean environments compared to dirty conditions.

Easier Maintenance and Higher Resale Value

Routine maintenance becomes simpler when engine bays remain clean and organized. Parts stay visible and accessible for inspections and repairs. Mechanics can diagnose issues faster in clean engine compartments compared to grimy ones.

Vehicle resale value increases when engine bays demonstrate proper care and maintenance. Potential buyers recognize well-maintained engines as indicators of overall vehicle condition. Clean engine compartments create positive first impressions during vehicle inspections.

These benefits collectively support better performance, enhanced safety, and improved longevity for vehicles that receive regular engine washing attention.

Common Mistakes to Avoid

Engine washing requires careful attention to prevent costly damage and electrical failures. Several critical errors can transform routine maintenance into expensive repairs.

Running engines during cleaning creates dangerous conditions that lead to electrical shorts and mechanical failures. Water enters moving components when we spray a running engine, causing immediate damage to sensitive parts.

Hot engine exposure presents important hazards during the cleaning process. Cold water on hot engines produces steam bursts, metal cracking, and component warping that compromises engine integrity.

High pressure washing forces water into electrical connectors, wiring harnesses, and component housings. This mistake causes corrosion and electrical failures that affect multiple engine systems simultaneously.

Careless debris removal clogs cowl drains and forces contaminants deeper into tight spaces. Improper spraying techniques cause water to pool inside vehicles, creating moisture damage throughout the engine bay.

Direct component exposure damages sensitive electrical parts during washing. We must avoid spraying water directly onto battery vents, alternator housing, engine computer modules, fuse boxes, and ignition coils to prevent electrical malfunctions.

Harsh chemical usage stains, fades, and degrades metal, plastic, and rubber components. Household cleaners and aggressive chemical answers cause permanent damage to engine bay materials and finishes.

Inadequate protective measures expose critical systems to water damage. Covering electrical connections, sensors, and air intake systems before cleaning prevents moisture infiltration and protects expensive electronic components from corrosion.

| Common Mistake | Potential Damage | Prevention Method |

|---|---|---|

| Running engine cleaning | Electrical shorts, mechanical failure | Turn off engine completely |

| Hot engine washing | Steam burns, metal cracking | Allow engine to cool |

| High pressure water | Electrical connector damage | Use low pressure settings |

| Direct component spraying | Electronic system failure | Cover sensitive areas |

| Harsh chemicals | Material degradation | Use automotive exact cleaners |

When to Seek Professional Engine Cleaning

Professional engine cleaning becomes essential when your vehicle presents exact maintenance challenges or operational demands. Complex engine configurations with intricate component layouts often require specialized tools and expertise that only certified technicians possess.

Vehicles operating in harsh environments benefit significantly from professional attention. Off-road vehicles and cars frequently exposed to heavy debris should receive professional engine cleaning every three months to maintain optimal performance. Coastal environments with salt exposure and dusty regions create additional challenges that warrant expert intervention.

| Vehicle Type | Professional Cleaning Frequency | Environmental Factor |

|---|---|---|

| Off-road vehicles | Every 3 months | Heavy debris exposure |

| Coastal vehicles | Every 3 months | Salt air corrosion |

| Urban commuters | Every 6 months | Pollution buildup |

| Highway vehicles | Every 6-12 months | Moderate exposure |

Early detection capabilities make professional services particularly valuable. Certified technicians perform detailed inspections during cleaning processes that identify potential issues like oil leaks, corroded components, and worn seals before they develop into major problems. These preventive assessments can save thousands in repair costs.

Safety considerations often dictate professional cleaning requirements. Trained technicians handle chemical degreasers and high-pressure equipment safely while protecting sensitive electrical components, sensors, and wiring harnesses. Modern vehicles contain many electronic systems that require specialized knowledge to clean without causing expensive malfunctions.

Environmental compliance represents another compelling reason for professional services. Licensed facilities use eco-friendly cleaning products and properly dispose of contaminated runoff according to environmental regulations. Professional operations follow strict protocols for chemical handling that individual car owners typically cannot replicate.

Access limitations in modern engine bays frequently exceed DIY capabilities. Turbocharged engines, hybrid systems, and densely packed component arrangements often require partial disassembly for thorough cleaning. Professional technicians possess the specialized tools and knowledge necessary to safely access all engine areas without damaging delicate components.

Conclusion

We’ve explored how engine washing stands as one of the most impactful yet overlooked maintenance practices for vehicle longevity. The combination of improved performance enhanced safety and increased resale value makes regular engine cleaning an investment rather than an expense.

Whether you choose the DIY approach or professional services depends on your vehicle’s complexity and operating conditions. Remember that consistency matters more than perfection – a regular cleaning schedule prevents the accumulation of harmful contaminants that lead to costly repairs.

Start incorporating engine washing into your maintenance routine today. Your vehicle’s performance reliability and your wallet will thank you for this proactive approach to automotive care.

Frequently Asked Questions

What is engine washing and why is it important?

Engine washing is a systematic cleaning process that removes dirt, grease, grime, and debris from the engine bay and external engine components. It’s important because it improves heat dissipation, prevents corrosive damage, extends the lifespan of rubber components, and makes it easier to identify fluid leaks. Regular engine washing also enhances performance and helps maintain your vehicle’s resale value.

How often should I wash my engine?

The frequency depends on your vehicle type and driving conditions. Standard passenger vehicles typically need engine washing every 6-12 months. However, off-road vehicles, coastal area vehicles, and those in dusty environments should be cleaned every 3 months. Urban vehicles exposed to pollution may also require more frequent cleaning to prevent buildup of contaminants.

What tools and products do I need for engine washing?

You’ll need automotive-specific degreasers (foam-based, spray-on, or water-based), low-pressure water source, protective gear (gloves, safety glasses), plastic bags or covers for electrical components, soft brushes for scrubbing, and clean rags for drying. Avoid household cleaners as they can damage engine materials and components.

Can I wash my engine while it’s running or hot?

No, never wash a running or hot engine. Washing a running engine can cause electrical shorts and damage. Cleaning a hot engine can lead to steam burns, metal cracking from rapid temperature changes, and potential damage to components. Always ensure the engine is cool and turned off before beginning the washing process.

What are the most common mistakes to avoid when washing an engine?

Key mistakes include washing a running or hot engine, using high-pressure water that can damage electrical connections, directly spraying sensitive components, and using non-automotive cleaners. Always cover electrical connections, allow the engine to cool completely, use low-pressure water, and choose products specifically designed for automotive use to prevent costly damage.

Should I hire a professional for engine cleaning?

Consider professional cleaning for vehicles with complex configurations, those operating in harsh environments, or if you’re uncomfortable with DIY cleaning. Professionals have specialized equipment, expertise with chemical degreasers, and knowledge of environmental compliance. They can also detect potential issues early, potentially saving you money on costly repairs down the road.

What are the benefits of regular engine washing?

Regular engine washing improves performance by ensuring optimal airflow and preventing overheating. It enhances safety by allowing early detection of leaks and reducing fire hazards. Clean engines also experience less corrosion, have extended component lifespan, simplified maintenance access, and higher resale value due to demonstrating proper vehicle care and maintenance.

Can engine washing damage my vehicle’s electrical systems?

Engine washing can damage electrical systems if done incorrectly. To prevent damage, always disconnect the battery, cover electrical connections with plastic bags, avoid high-pressure water near sensitive components, and ensure thorough drying afterward. Using automotive-specific cleaners and following proper techniques will minimize the risk of electrical damage during the cleaning process.