Navigating the roads in our Nissan vehicles, we’ve come to rely on the advanced technology that makes every journey smoother and safer. Among these innovations, the chassis control system stands out as a critical component, ensuring stability and control under various driving conditions. But what happens when this system encounters a fault?

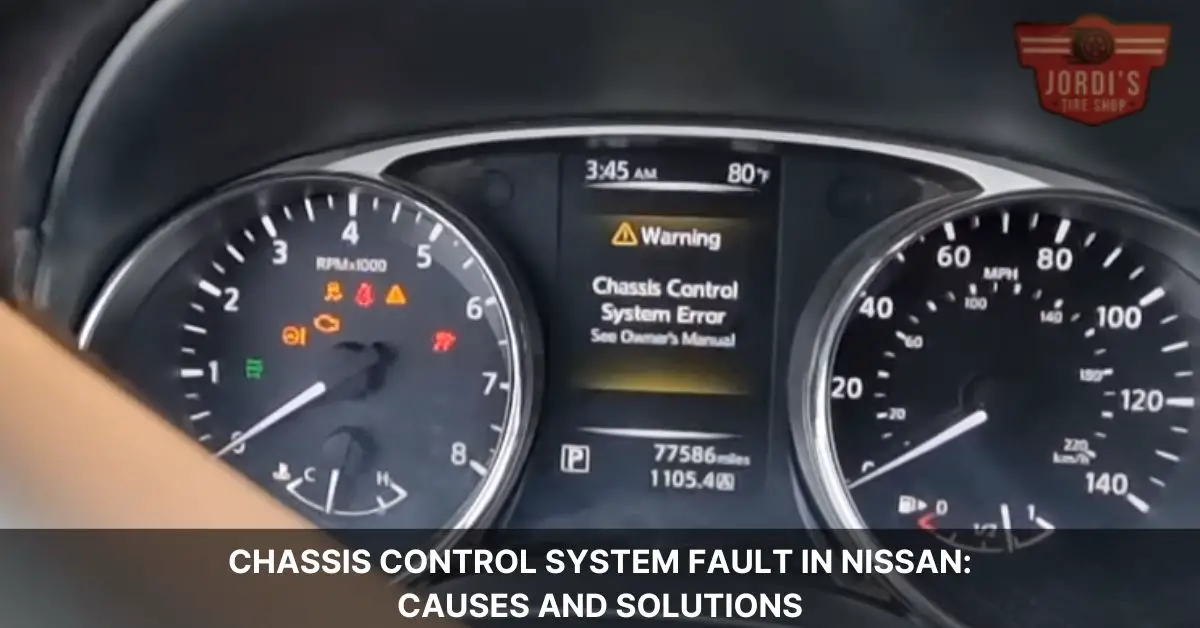

Encountering a chassis control system fault in a Nissan can be a puzzling experience. It’s a moment filled with questions and concerns about safety, costs, and the next steps. We understand the importance of addressing these issues head-on, armed with knowledge and a plan of action.

In this article, we’ll dive into the common causes of chassis control system faults in Nissan vehicles, offering insights and solutions to get you back on the road with confidence. Whether you’re a seasoned Nissan driver or new to the brand, we’re here to shed light on this complex topic, ensuring your driving experience remains as seamless as ever.

Understanding Chassis Control System Fault in Nissan

After discussing the critical role the chassis control system plays in maintaining stability and control in Nissan vehicles, it’s essential we delve into what exactly a chassis control system fault means and how it can impact your driving experience. When a fault occurs, this sophisticated system, responsible for optimizing the car’s stability through various sensors and actuaries, signals a malfunction that could compromise your vehicle’s safety and performance.

A chassis control system fault in Nissan cars could stem from numerous issues, ranging from sensor malfunctions to software glitches. Sensors are the system’s eyes and ears, providing real-time data on vehicle dynamics such as speed, steering angle, and braking force. If a sensor fails or sends incorrect data, the control system might not operate as intended, leading to warning messages or visible signs of system failure.

Software in modern vehicles is as crucial as the mechanical parts. An error in the system’s software can lead to incorrect calculations or responses from the control system. This could manifest as unusual behavior in the vehicle’s handling or unexpected activation of stability control features.

Electrical issues, such as faulty wiring or connector problems, also contribute to chassis control system faults. Since the system relies on electrical signals to function, any disruption in these signals can cause system malfunctions.

Diagnosing a chassis control system fault requires a thorough understanding of the vehicle’s diagnostic codes, which can be obtained using a professional diagnostic tool. These codes offer insights into which component or system section may be malfunctioning, providing a starting point for addressing the fault.

Diagnosing Chassis Control System Faults

When a “chassis control system fault” message appears in a Nissan vehicle, it signals us to take immediate action. Diagnosing these faults appropriately relies on our understanding of the vehicle’s sophisticated systems and the deployment of right diagnostic tools. Let’s explore the steps and tools necessary for diagnosing these faults.

Understanding Diagnostic Codes

The first step in diagnosing a chassis control system fault involves retrieving diagnostic trouble codes (DTCs) from the vehicle’s onboard computer. These codes provide specific information about the nature of the fault, pinpointing whether the issue lies with a sensor, software, or an electrical component. Using a professional-grade diagnostic scanner, we access these codes, which serve as a guide to narrowing down potential problems.

Employing Professional Diagnostic Tools

Professional diagnostic tools play a crucial role in accurately diagnosing chassis control system faults. These tools not only read DTCs but also offer real-time data monitoring, sensor testing, and software updates. This allows us to observe how the chassis control system performs under various conditions, identifying anomalies that might not trigger a DTC.

Interpreting Data and Tests

After collecting data and running tests, interpreting the results is our next step. For instance, if a wheel speed sensor shows inconsistencies during real-time monitoring, it likely indicates a malfunctioning sensor, which could be causing the system fault. Similarly, if a software version is outdated, updating it might resolve the fault without the need for hardware repairs.

Regular Maintenance Checks

Regular checks are essential for preempting potential issues with the chassis control system. These checks include inspecting wiring connectors for corrosion, ensuring sensors are clean and unobstructed, and verifying that software is up to date. By maintaining a proactive approach, we often prevent minor issues from escalating into major faults.

In diagnosing chassis control system faults in Nissan vehicles, using the right diagnostic tools and having a keen understanding of the DTCs are paramount. Skillful interpretation of diagnostic data and preventive maintenance are our best tools for addressing these issues, ensuring our Nissan vehicles remain reliable and safe on the road.

Common Causes of Chassis Control System Faults in Nissan

Following our discussion on the significance of promptly addressing chassis control system faults in Nissan vehicles, we delve into the common causes behind these issues. Understanding these triggers helps us preempt potential problems and maintain our vehicles’ safety and reliability.

- Sensor Malfunctions: Sensors play a crucial role in the chassis control system, monitoring variables like wheel speed, vehicle tilt, and yaw rate. Malfunctioning sensors, often due to dirt accumulation, wear, or damage, can transmit incorrect data, triggering faults in the system.

- Wiring Issues: Wiring connections between the chassis control system’s components are essential for the smooth operation of this network. Corrosion, wear, or impact damage can disrupt these connections, leading to intermittent or total system failures.

- Software Glitches: The software that governs the chassis control system is sophisticated, managing numerous inputs to ensure the vehicle’s stability and responsiveness. Occasionally, glitches or outdated firmware can cause the system to behave unpredictably.

- Component Wear and Tear: Over time and with use, mechanical components such as steering linkage and suspension parts can wear out. This wear and tear can affect the chassis control system’s accuracy, diminishing the vehicle’s handling characteristics.

- Power Supply Problems: A stable power supply is vital for the chassis control system’s operation. Issues like weak batteries or malfunctioning charging systems can lead to inadequate power for the system, manifesting as faults.

Repairing Chassis Control System Faults

Understanding the common causes behind chassis control system faults in Nissan vehicles sets the stage for the next critical step: repairing these issues. Addressing the repair process involves a systematic approach, beginning with accurate diagnostics and culminating in precise, sometimes intricate, interventions to restore the system’s integrity.

Diagnosing the Problem

Diagnosis starts with connecting a professional-grade diagnostic tool to the vehicle’s onboard computer. This tool reads out diagnostic trouble codes (DTCs) that pinpoint the origins of the fault. Each code corresponds to a specific issue within the chassis control system, enabling technicians to focus their repair efforts efficiently.

Addressing Sensor Malfunctions and Wiring Issues

Sensors and wiring are frequent trouble spots. Repairing sensor-related issues often requires replacing faulty sensors and recalibrating the system to ensure accurate data transmission. For wiring issues, technicians inspect and repair any damaged wires or connections, safeguarding the integrity of electrical pathways.

Software Updates

At times, software glitches contribute to chassis control system faults. Here, the remedy involves updating the vehicle’s software to the latest version. Dealerships and authorized service centers have the necessary tools and access to manufacturer-supplied updates, ensuring the software is current and fully compatible with all system components.

Component Replacement and Power Supply Corrections

Worn or damaged components, such as the control module or power supply units, require direct replacement. Choosing genuine Nissan parts guarantees compatibility and performance. Additionally, if power supply problems are detected, repairing or replacing the affected components restores the necessary power levels to the chassis control system.

Regular Maintenance Checks

Finally, preemptive care through regular maintenance checks plays a vital role in preventing future faults. These checks include inspecting sensors, wiring, software versions, and hardware condition, helping avoid the recurrence of similar issues.

Preventing Future Chassis Control System Faults

Given that we’ve explored how to tackle chassis control system faults in Nissan vehicles, including understanding diagnostic trouble codes and undertaking precise interventions, it’s equally important to prevent such issues from recurring. Preventive measures not only enhance the safety and reliability of your Nissan but also contribute to a smoother driving experience. Here are several steps we recommend to avoid future faults in the chassis control system.

- Schedule Regular Maintenance Checks: Regular visits to a certified mechanic can catch potential problems before they escalate. Mechanics can inspect sensors, wiring, and other critical components for wear and tear or damage.

- Keep Software Updated: Software glitches often lead to faults. Manufacturers occasionally release updates to vehicle software to address these glitches. Ensure your vehicle’s software is up-to-date to avoid such issues.

- Monitor Battery Health: A weak or failing battery can indirectly lead to chassis control system faults. Keeping the battery in good condition ensures that all electronic systems, including the chassis control system, function optimally.

- Avoid Harsh Driving Conditions: Frequently driving in harsh conditions can accelerate the wear of vehicle components. Whenever possible, opt for smoother routes and avoid excessive speeds to minimize strain on the chassis control system.

- Familiarize Yourself with Warning Signs: Understanding early warning signs, such as unusual noises or changes in vehicle handling, can help you address issues promptly before they evolve into significant faults.

- Use Genuine Replacement Parts: In case of replacements, using parts recommended by the manufacturer ensures compatibility and reliability, reducing the chances of future faults.

Conclusion

We’ve walked through the steps of addressing and preventing chassis control system faults in Nissan vehicles. By staying informed and proactive we can ensure our cars remain safe and reliable on the road. Let’s not forget the value of regular maintenance and the use of genuine parts to keep our Nissans running smoothly. Together we can tackle these challenges head-on enhancing our driving experience for miles to come.

Related Posts: