When it comes to maintaining our vehicles, we all want to save time and money without compromising on quality. One of the more daunting tasks can be replacing the lifters in a 5.3 engine. Traditionally, this job suggests removing the head, which is both time-consuming and costly. But what if we told you there’s a way to bypass this step?

We’ve discovered a method that allows for 5.3 lifter replacement without removing the head, and we’re eager to share it with you. This approach not only saves precious hours but also keeps a few extra dollars in your pocket. Join us as we dive into the details of this game-changing procedure that’s making waves among DIY enthusiasts and professional mechanics alike.

Understanding the 5.3 Lifter Replacement Process

Building on the innovative method that enables lifter replacement without the hassle of removing the head, we explore the steps involved in this process. It’s crucial for both DIY enthusiasts and professional mechanics to grasp these steps to ensure a smooth and efficient replacement.

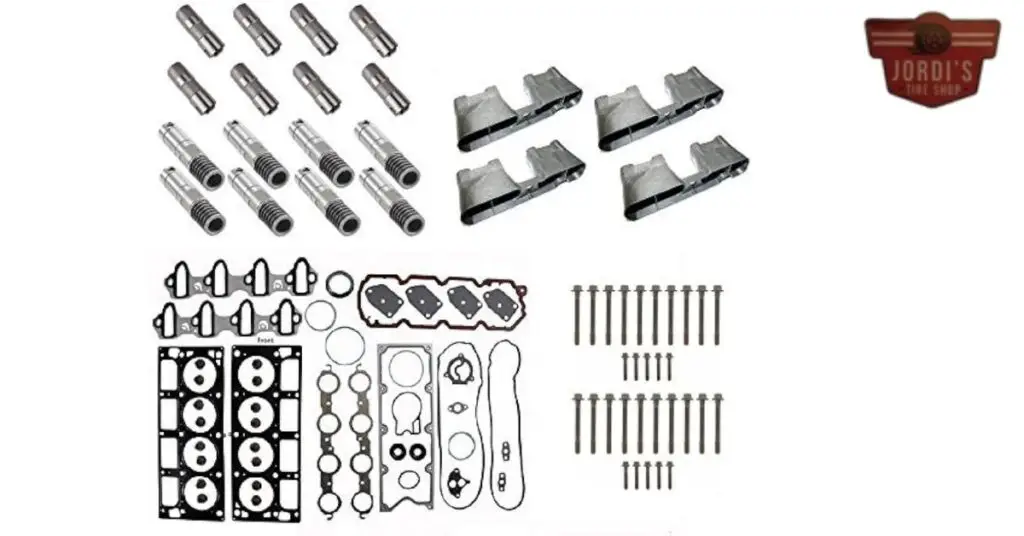

First, we gather the necessary tools and parts. Essential items include a quality lifter removal tool, new lifters, and possibly, new gaskets and seals to avoid any leaks post-replacement.

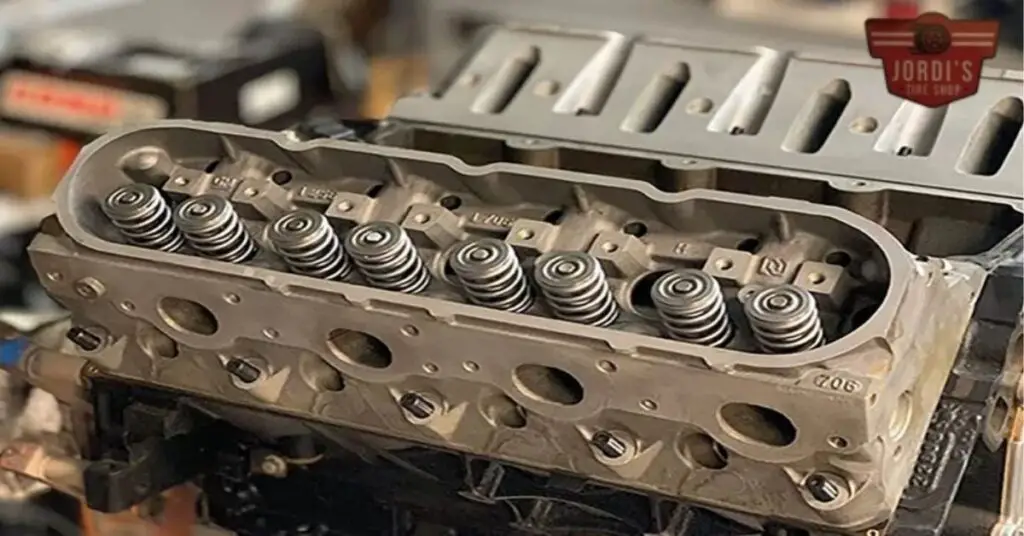

Next, we access the affected lifters. To do this, we carefully remove the engine cover and any components obstructing the lifters. This step requires patience and precision to avoid damaging any surrounding parts.

Once we have clear access, we use the lifter removal tool to extract the faulty lifters carefully. This tool is instrumental in performing the replacement without needing to remove the head, as it allows us to pull the lifters straight out from their seating.

After removing the old lifters, we clean the lifter bores thoroughly. Removing any debris or buildup is key to ensuring the new lifters can operate smoothly.

We then insert the new lifters. It’s essential to lubricate them well with engine oil before installation to reduce initial wear and ensure they move freely in their bores.

Re-assembly follows the insertion of the new lifters. This involves carefully putting back any components we removed earlier and ensuring everything is sealed correctly to prevent leaks.

Finally, we perform a thorough check of our work. This includes verifying that all parts are securely in place and there are no signs of leakage. We also recommend running the engine and listening for any unusual noises that might indicate improper installation.

Understanding these steps, we can tackle lifer replacement confidently, saving time and money by not removing the engine head. This method not only simplifies the task but also highlights the importance of precision and careful handling of engine components.

Preparing Your Vehicle for Lifter Replacement

Preparing your vehicle for a 5.3 lifter replacement without removing the head involves several key steps to ensure a smooth and successful process. After outlining the innovative approach to replacing lifters, let’s dive into how to best prepare your vehicle for this task.

First, ensure the vehicle is parked on a level surface and the engine is cool. This safety measure prevents accidents and makes the working environment more manageable.

Next, disconnect the battery to safeguard against electrical shorts or unwanted power surges. This is a critical step in preventing damage to the vehicle’s electrical systems.

Remove any components obstructing access to the cylinder head. Components such as the intake manifold, valve cover, and possibly the exhaust manifold often require removal. Each vehicle may have a slightly different configuration, so refer to the vehicle’s service manual for exact instructions.

Drain the coolant from the engine to avoid spills and potential messes when parts are removed. This step also reduces the risk of mixing oil and coolant, which can complicate the replacement process.

It’s important to label and organize the parts and their corresponding fasteners as they’re removed. This organization aids in the reassembly process, ensuring no steps are missed and everything is reinstalled correctly.

Ensure you have a clean workspace to lay out the parts as they’re removed. Keeping the work area tidy not only helps in keeping track of everything but also prevents contamination of engine components.

Lastly, prepare a set of tools including wrenches, sockets, a torque wrench, and a lifter removal tool. Having the right tools within reach streamlines the replacement process, making it more efficient.

Following these preparation steps, we create a safe and orderly environment conducive to a successful lifer replacement procedure. Proper preparation not only facilitates a smoother operation but also lays the groundwork for a successful repair, ensuring the longevity and performance of the 5.3 engine.

Step-by-Step Guide to Replacing Lifters Without Removing the Head

Building on our preparation process, we’ll dive straight into the step-by-step guide for replacing lifters on a 5.3 engine without the need to remove the head. This allows us to maintain the engine’s integrity while saving both time and resources. It’s essential to follow each step closely to ensure a smooth and effective lifter replacement.

- Access the Valve Cover: First, we carefully remove the valve cover. This step exposes the lifters and allows us access to the parts that need replacement. Remember, keeping track of all screws and parts is vital for reassembly.

- Position the Engine: Turning the engine to ensure the cam lobes are not pressing down on the lifters we’re about to remove is our next move. This position reduces tension, facilitating easier lifter removal.

- Remove Old Lifters: Utilizing a lifter removal tool, we extract the faulty lifters. This specialized tool is crucial for removing lifters without head removal, ensuring we don’t damage any other components in the process.

- Clean and Inspect the Bores: With the old lifters out, we take the opportunity to clean the lifter bores thoroughly. Inspection for wear or damage is crucial. If we find bore damage, further engine work might be necessary.

- Lubricate and Install New Lifters: Before installation, lubricating the new lifters ensures they slide in smoothly and operate efficiently once the engine is running. Carefully, we insert each new lifter into its bore, ensuring proper alignment.

- Reassemble Engine Components: Following the new lifters installation, we meticulously reassemble the removed components. This includes putting back the valve cover and ensuring all connections are secure.

- Conduct a Final Check: Finally, we double-check our work. Making sure every part is in its right place and tightly secured guarantees we won’t run into issues when we start the engine.

- Start the Engine and Monitor: Starting the engine, we listen for any unusual noises and monitor for smooth operation. It’s also wise to check for leaks and any signs of improper installation.

Through these steps, we’ve tackled lifter replacement without removing the engine head, optimizing both time and cost. Remember, patience and attention to detail are key to successful lifter replacement on a 5.3 engine.

Tips and Tricks for a Smooth Process

When tackling the task of replacing lifters on a 5.3 engine without removing the head, we’ve gathered some essential tips and tricks that make the process smoother and more manageable. From our detailed guide, these pointers will serve as your beacon, guiding you through each step with efficiency and ensuring a successful outcome.

Gather All Necessary Tools Before Beginning

First and foremost, ensure you have all required tools and parts on hand before starting the job. This preparation includes not just basic tools but also a lifter removal tool, new lifters, and lubricants. Having everything at your fingertips prevents unnecessary pauses and trips to the store mid-process.

Double-Check the Lifter Compatibility

Accuracy in selecting the correct lifters for your 5.3 engine model is crucial. Double-checking the compatibility of your new lifters with your engine model ensures that you won’t face performance issues down the line.

Use Magnetic Tools for Easy Lifter Removal

Investing in a magnetic tool to remove the old lifters can be a game-changer. These tools make it significantly easier to extract the lifters without accidentally dropping them into hard-to-reach areas of the engine.

Ensure a Clean Working Environment

Keeping the work area and the lifter bores as clean as possible throughout the process is paramount. This cleanliness prevents debris from entering the engine, potentially leading to severe damage. Use appropriate cleaning agents and tools to clean the bores thoroughly before installing new lifters.

Take Your Time During Reassembly

Rushing through the reassembly of engine components increases the risk of mistakes. Take your time to carefully position and secure each part, double-checking your work as you go. This attention to detail ensures that everything is correctly in place, reducing the risk of issues during the final check.

Keeping these tips in mind, you lay the groundwork for a successful lifter replacement on your 5.3 engine without the need to remove the head. Each tip brings you closer to a smooth and efficient process, saving time and ensuring your engine operates at its best once you’re finished.

The Pros and Cons of Not Removing the Head

After walking through the step-by-step process of replacing lifters in a 5.3 engine without removing the head, it’s important to weigh the pros and cons of this method. Doing so will help ensure that you make an informed decision tailored to your situation.

Pros

- Time and Cost Efficiency: One of the biggest advantages is the significant savings in both time and costs. By not removing the head, you avoid the need for new head gaskets and potentially long hours or days added to the project.

- Less Complexity: This method reduces the complexity of the job. You don’t have to deal with the additional steps and precautions required when taking off and reinstalling the engine head.

- Convenience: For those with limited tools, space, or expertise, avoiding head removal makes the lifter replacement process more accessible and less daunting.

Cons

- Limited Accessibility: Not removing the head limits your access and visibility. It makes it challenging to assess and clean the lifter bore with the same thoroughness as you would through head removal.

- Potential for Mistakes: Working in a more restricted space increases the risk of mistakes, such as improperly seating a lifter, which could lead to engine damage or necessitate redoing the process.

- Incomplete Inspection: Without removing the head, you miss the opportunity to inspect it for other potential issues, like valve damage or wear, which could be preemptively addressed.

Choosing not to remove the head for a 5.3 lifter replacement leans heavily towards convenience and efficiency. However, it requires careful consideration of the potential downsides, particularly regarding the detailed inspection and the precision required in the restricted workspace. We aim to guide you through making the best choice based on your skills, tools, and the specific conditions of your engine. Balancing these factors will help ensure that your engine operates smoothly and reliably after the replacement.

Conclusion

We’ve walked through the steps and weighed the advantages and disadvantages of replacing lifters on a 5.3 engine without taking off the head. It’s clear that this method can save us both time and money while still maintaining a high level of efficiency. However, it’s not without its challenges. Restricted access and the potential for errors remind us that this task requires careful consideration and a bit of skill.

Ultimately, armed with the right tools and a clear understanding of the process, we’re in a great position to decide whether this approach is right for us. Whether we’re seasoned mechanics or enthusiastic DIYers, ensuring our engine runs smoothly without unnecessary complications is our goal. Here’s to successful lifter replacements and the satisfaction of a job well done.

Related Posts:

- 2021 Mitsubishi Outlander Sport Towing Capacity: A Friendly Guide

- A Guide to the “A in a Circle” Symbol on Your Car

- Big O Tire Installation Fee: What You Need to Know

- Biggest Tires for 18 Inch Rims: A Comprehensive Guide

- Mechanic for European Cars: Expertise and Affordable Services

- Radio Keeps Changing Stations By Itself: How to Fix It

- Semi Truck Tire Position Diagram: A Helpful Guide for Drivers

- Mitsubishi Staten Island: Your Ultimate Guide to Finding the Best Dealership

- Ford 3.3 V6 Problems: Common Issues and Solutions

- 5.3 Lifter Replacement Made Easy Without Removing Head