We’ve all heard the distinctive roar of a high-performance engine but few understand the crucial component that makes it all possible: the copa piston. These precision-engineered marvels sit at the heart of every combustion engine transforming fuel into the raw power that moves our vehicles forward.

When we talk about automotive performance the piston’s design directly impacts everything from horsepower output to fuel efficiency. The copa piston’s unique shape and materials determine how effectively your engine converts energy while managing the extreme pressures and temperatures inside each cylinder.

Whether you’re a weekend mechanic looking to upgrade your ride or simply curious about what’s happening under your hood understanding copa pistons opens up a intriguing area of automotive engineering. We’ll explore how these critical components work their magic and why choosing the right piston can transform your driving experience.

Understanding Copa Piston Components in Modern Cars

Now that we’ve covered the importance of copa pistons in performance applications, let’s dive deeper into their construction and unique characteristics.

What Are Copa Pistons and Their Function

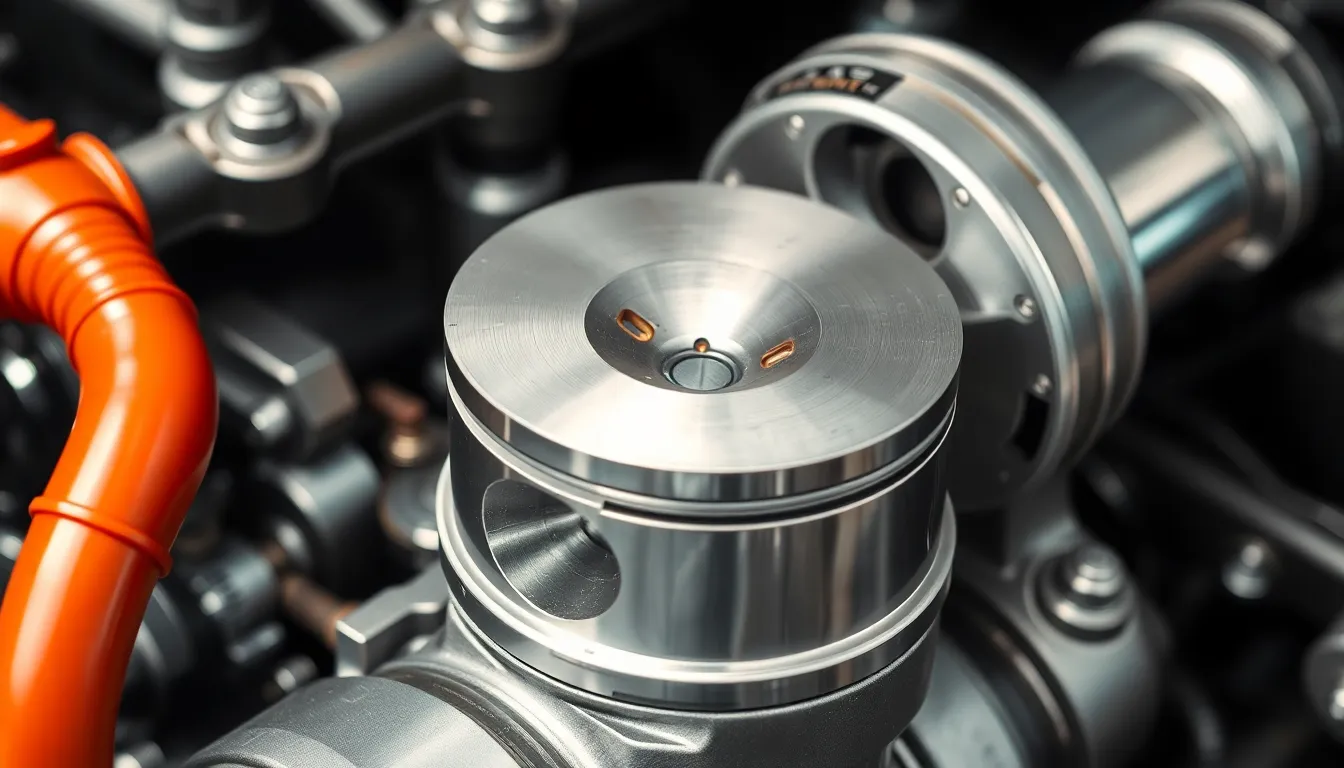

Copa pistons are specialized engine components designed with a distinctive cup-shaped crown that creates optimal combustion chamber geometry. We find these pistons primarily in high-performance and racing applications where precise air-fuel mixture control becomes critical. The crown’s unique shape allows for better flame propagation and reduced combustion chamber volume, which directly impacts compression ratios and power output.

These pistons work by compressing the air-fuel mixture in the cylinder during the compression stroke. When combustion occurs, the gases expand and push the piston down, transferring energy through the connecting rod to the crankshaft. The copa design enhances this process by creating turbulence that promotes complete fuel burn and reduces knock tendency.

Key Materials Used in Copa Piston Manufacturing

Aluminum alloys remain the most common material for copa piston construction, with manufacturers often using 2618 or 4032 aluminum for different applications. We see 2618 aluminum in extreme performance builds because it offers superior strength at high temperatures, though it requires more precise clearances due to higher thermal expansion rates.

Forged aluminum provides the strongest option for copa pistons, withstanding pressures exceeding 2,000 PSI in turbocharged applications. Cast aluminum offers a more economical choice for street performance builds where extreme conditions aren’t expected.

Some manufacturers incorporate ceramic coatings on the crown and skirts to reduce heat transfer and friction. These coatings can lower operating temperatures by 50-100 degrees Fahrenheit, extending component life and maintaining consistent performance under stress.

How Copa Pistons Differ from Standard Pistons

Standard flat-top pistons create a simple combustion chamber shape, while copa pistons feature the distinctive dish or cup in their crown. We observe that this fundamental design difference affects compression ratios, with copa pistons typically reducing static compression by 0.5 to 1.5 points depending on the dish volume.

Valve reliefs in copa pistons are often more pronounced than in standard designs, allowing for aggressive camshaft profiles without interference issues. The dish also provides clearance for larger intake and exhaust valves commonly found in performance cylinder heads.

Weight distribution differs significantly between these piston types. Copa pistons often weigh 10-15% more than standard pistons due to their specialized crown geometry, requiring careful attention to reciprocating assembly balance. This additional mass sits higher in the piston, affecting the overall center of gravity and potentially requiring different connecting rod considerations.

Identifying Signs Your Copa Piston Needs Replacement

Recognizing early warning signs of copa piston failure can save us from costly engine damage and performance issues. We’ll explore the most common symptoms that indicate our specialized pistons need immediate attention.

Engine Knocking and Unusual Noises

Engine knocking represents the most obvious sign of copa piston distress in our high-performance applications. We hear this metallic rattling sound when the piston crown develops cracks or when excessive clearances allow the piston to rock within the cylinder bore.

Rattling noises during cold starts often indicate worn piston skirts or damaged ring lands on our copa pistons. These sounds typically diminish as the engine warms up and components expand to their operating dimensions.

Clicking sounds from the combustion chamber suggest our piston pin bushings have worn beyond acceptable tolerances. We notice this symptom most prominently during idle conditions when other engine noises don’t mask the piston movement.

Sharp knocking under load points to severe piston damage or complete ring failure in our copa piston assembly. This condition requires immediate shutdown to prevent catastrophic engine damage.

Loss of Power and Poor Acceleration

Power loss becomes apparent when our copa pistons can no longer maintain proper compression ratios due to ring wear or crown damage. We experience sluggish throttle response and reduced peak horsepower output during high-RPM operation.

Acceleration problems manifest when damaged copa pistons fail to seal combustion pressure effectively against the cylinder walls. Our engines struggle to build power throughout the RPM range, particularly noticeable during wide-open throttle applications.

Misfiring symptoms occur when our copa piston crowns develop cracks that allow combustion pressure to escape. We feel rough idle conditions and inconsistent power delivery across all operating ranges.

Performance degradation in racing applications becomes evident through slower lap times and reduced straight-line speed. Our copa pistons lose their ability to optimize combustion chamber dynamics when wear exceeds design specifications.

Excessive Oil Consumption Symptoms

Oil consumption increases dramatically when our copa piston rings lose their sealing ability against the cylinder walls. We notice blue smoke from the exhaust during startup and acceleration phases, indicating oil entering the combustion chamber.

Ring gap expansion allows excessive oil passage past worn copa piston assemblies during operation. We observe oil level drops between service intervals and may need frequent top-offs to maintain proper lubrication levels.

Blow-by symptoms appear when our copa pistons develop excessive clearances that allow combustion gases to escape past the rings. This condition creates pressure in the crankcase and forces oil vapors through the PCV system.

Carbon buildup on spark plugs indicates oil burning within our combustion chambers due to failed copa piston ring sealing. We see black, wet deposits on electrode surfaces and may experience fouled ignition components.

Choosing the Right Copa Piston for Your Vehicle

Selecting the appropriate copa piston requires understanding your engine’s exact requirements and performance goals. We’ll examine the critical factors that determine the best copa piston choice for your vehicle.

OEM vs Aftermarket Copa Piston Options

OEM copa pistons provide guaranteed compatibility with your vehicle’s original specifications. These factory components maintain the exact compression ratios and valve reliefs designed for your engine, ensuring reliable performance and longevity. Original equipment manufacturers typically use proven aluminum alloys like 4032, which offer excellent thermal expansion characteristics for daily driving applications.

Aftermarket copa pistons deliver enhanced performance capabilities beyond factory specifications. Companies like Wiseco, JE Pistons, and CP Pistons manufacture copa pistons using superior 2618 aluminum alloys that withstand extreme temperatures and pressures. These pistons often feature advanced ceramic coatings that reduce heat transfer by up to 20% compared to standard OEM options.

Performance-focused aftermarket options include forged construction that increases strength by approximately 25% over cast pistons. We find these pistons particularly beneficial for turbocharged applications where cylinder pressures exceed 1,500 PSI. Racing-grade copa pistons also incorporate optimized skirt designs that reduce friction and improve oil control.

Cost considerations favor OEM replacements for stock applications, typically ranging from $150-300 per set. Aftermarket performance copa pistons command premium prices between $400-800 per set but deliver measurable power gains and durability improvements for modified engines.

Compatibility Factors to Consider

Engine displacement determines the fundamental piston dimensions required for your application. We must match bore diameter, stroke length, and compression height specifications precisely to ensure proper fitment. Standard bore sizes for popular V8 engines include 4.000″, 4.030″, and 4.125″, while compression heights typically measure 1.560″ or 1.200″ depending on the engine family.

Connecting rod compatibility affects piston pin diameter selection, with common sizes including 0.927″, 0.990″, and 1.000″. Mismatched pin diameters create excessive clearances that lead to premature wear and potential engine failure. We recommend verifying rod specifications before ordering copa pistons to avoid costly compatibility issues.

Valve relief requirements depend on camshaft profiles and valve lift specifications. High-performance camshafts with lift exceeding 0.600″ require deeper valve pockets to prevent interference. Copa pistons designed for naturally aspirated engines may lack sufficient clearance for forced induction applications where valve timing events differ significantly.

Deck height measurements influence compression ratio calculations and must align with your performance objectives. We calculate static compression ratios using chamber volume, piston volume, and deck clearance measurements. Target compression ratios typically range from 9.5:1 for turbocharged applications to 12.5:1 for naturally aspirated racing engines.

Performance Specifications and Ratings

Compression ratio specifications directly impact power output and fuel requirements for your engine. Copa pistons with volumes ranging from 5cc to 23cc allow fine-tuning of compression ratios to match fuel octane ratings and boost levels. We recommend compression ratios between 8.5:1 and 9.5:1 for turbocharged applications using pump gasoline.

Thermal expansion coefficients vary between aluminum alloy compositions, affecting piston-to-wall clearances. 2618 aluminum alloys expand approximately 15% more than 4032 alloys, requiring increased bore clearances of 0.0045-0.0055″ for optimal performance. These wider clearances prevent seizure during extreme temperature conditions but may increase oil consumption during cold startup periods.

Weight specifications influence rotating assembly balance and engine responsiveness. Standard copa pistons weigh between 450-650 grams depending on bore size and design features. Lightweight racing pistons reduce reciprocating mass by up to 100 grams per piston, improving throttle response and reducing bearing loads at high RPM operation.

| Piston Type | Weight Range | Compression Ratio | Max RPM | Price Range |

|---|---|---|---|---|

| OEM Copa | 500-600g | 9.0-10.5:1 | 6,500 RPM | $150-300 |

| Street Performance | 450-550g | 8.5-11.5:1 | 7,500 RPM | $300-500 |

| Racing Copa | 400-500g | 8.0-13.0:1 | 9,000+ RPM | $500-800 |

Temperature resistance ratings determine maximum operating conditions for different copa piston designs. Standard pistons handle continuous temperatures up to 400°F, while ceramic-coated versions withstand 500°F without degradation. We specify these ratings based on crown temperature measurements rather than exhaust gas temperatures for accurate performance assessment.

Installing Copa Pistons: Professional vs DIY Approach

Installing copa pistons requires careful consideration between professional installation and the DIY approach, as this decision impacts both performance outcomes and long-term engine reliability.

Required Tools and Equipment

Essential tools for copa piston installation include a complete socket set ranging from 8mm to 19mm, torque wrenches capable of 15-150 ft-lbs, and precision measuring instruments like micrometers and dial bore gauges. Specialized equipment encompasses a piston ring compressor, connecting rod bolt stretch gauge, and plastigauge for bearing clearance verification.

Professional shops use engine stands, pneumatic tools, and computerized torque systems that ensure consistent results across installations. DIY enthusiasts need clean workspace areas, proper lighting systems, and organized tool storage to maintain component cleanliness during assembly.

Safety equipment includes nitrile gloves, safety glasses, and respirators when handling machining residues or cleaning solvents. Cleaning supplies require brake cleaner, lint-free rags, and assembly lubricants specifically designed for high-performance applications.

| Tool Category | Professional Grade | DIY Alternative | Price Range |

|---|---|---|---|

| Torque Wrench | Digital with angle measurement | Click-type calibrated | $150-$800 |

| Ring Compressor | Adjustable tapered design | Standard band style | $45-$200 |

| Bore Gauge | Digital readout system | Telescoping manual gauge | $200-$1,200 |

| Assembly Lube | Racing-exact compounds | Standard engine assembly oil | $25-$75 |

Step-by-Step Installation Process

Preparation begins with complete engine disassembly and thorough cleaning of all components, ensuring machined surfaces remain free from debris and contaminants. Cylinder measurement involves checking bore diameters, taper, and out-of-round conditions using precision gauges at multiple points.

Piston fitting requires measuring ring end gaps, typically 0.004-0.006 inches per inch of bore diameter for top rings, and verifying side clearances between rings and grooves. Ring installation follows exact orientation patterns with gaps positioned 120 degrees apart to prevent pressure loss.

Assembly lubrication uses thin coats of assembly oil on cylinder walls, piston skirts, and ring surfaces to prevent scuffing during initial startup. Rod bearing installation demands precise torque specifications, usually 25-35 ft-lbs for most applications, plus additional angle rotation as specified by manufacturers.

Professional installations include bore honing, deck surface preparation, and computerized balancing that DIY approaches typically cannot replicate. Final verification involves checking compression ratios, piston-to-valve clearances, and overall deck height measurements before completing assembly.

Common Installation Mistakes to Avoid

Ring orientation errors occur when installers fail to properly align ring gaps or install rings upside down, leading to excessive oil consumption and poor sealing. Inadequate clearance checking results in interference conditions between pistons and cylinder walls, causing catastrophic engine damage during operation.

Improper torque procedures include using incorrect specifications, failing to follow angle torque requirements, or reusing stretch bolts beyond their service limits. Contamination issues arise from insufficient cleaning, using dirty assembly lubricants, or working in dusty environments.

Measurement oversights happen when DIY installers skip critical steps like checking piston-to-valve clearances, deck height verification, or connecting rod length measurements. Assembly sequence mistakes involve installing components in wrong orders, forgetting gasket sealers, or mixing up piston orientations between cylinders.

Professional advantages include access to machining equipment, experience with torque specifications, and ability to correct dimensional issues discovered during installation. DIY risks cover potential engine damage from measurement errors, lack of proper tools, and inexperience with high-performance assembly techniques that copa pistons require for optimal performance.

Maintaining Copa Pistons for Optimal Performance

Proper maintenance is crucial for maximizing copa piston performance and extending their operational lifespan in high-performance engines. Regular care prevents premature wear and ensures these specialized components continue delivering optimal combustion efficiency.

Regular Oil Change Intervals

We recommend changing engine oil every 3,000 to 5,000 miles for copa piston engines, significantly shorter than standard maintenance intervals. High-performance applications generate more heat and stress, causing oil to break down faster and lose its protective properties.

Using high-quality synthetic oil provides superior lubrication and thermal stability for copa pistons. Choose oils with viscosity ratings between 5W-30 and 10W-40, depending on your engine’s specifications and operating conditions.

Oil analysis every 2-3 changes helps identify potential copa piston wear patterns. Metal particles in oil samples can indicate ring wear, cylinder wall damage, or other internal components requiring attention.

Frequent oil filter replacements ensure contaminants don’t circulate through your engine. We suggest replacing filters with every oil change rather than following extended service intervals recommended for standard engines.

Engine Temperature Management

Maintaining optimal operating temperatures between 180°F and 210°F protects copa pistons from thermal expansion damage. Excessive heat can cause piston crown cracking, ring gap closure, and catastrophic engine failure.

Installing a high-capacity cooling system becomes essential for copa piston engines. Upgraded radiators, electric fans, and performance water pumps help maintain consistent temperatures during demanding driving conditions.

Temperature monitoring through digital gauges provides real-time feedback on engine conditions. We recommend installing separate gauges for coolant temperature, oil temperature, and exhaust gas temperature for comprehensive monitoring.

Thermostat selection affects copa piston longevity significantly. Lower-temperature thermostats (160°F-180°F) help reduce peak combustion chamber temperatures while maintaining proper engine warm-up cycles.

Fuel Quality Considerations

Using premium fuel with octane ratings of 91 or higher prevents detonation that can damage copa piston crowns. Lower octane fuel increases knock tendency, especially in high-compression applications where copa pistons are commonly used.

Fuel additives containing detergents help prevent carbon buildup on copa piston surfaces. Clean combustion chambers ensure proper heat transfer and prevent hot spots that can cause pre-ignition or detonation.

Ethanol content should remain below 10% to avoid potential corrosion issues with copa piston coatings. Higher ethanol concentrations can degrade protective ceramic coatings and accelerate component wear over time.

Regular fuel system cleaning maintains optimal fuel delivery to copa piston engines. We suggest professional fuel system service every 30,000 miles or according to severe service schedules for performance applications.

Top Brands Manufacturing Copa Pistons for Cars

Several manufacturers have established themselves as leaders in copa piston production, each offering unique advantages for different performance applications. We’ve analyzed the most reputable brands to help you make informed decisions about your engine upgrades.

Industry-Leading Manufacturers

Wiseco Performance Products leads the racing piston market with their forged aluminum copa designs that handle extreme RPMs and boost pressures. Their pistons feature advanced skirt coatings and precise valve reliefs, making them ideal for turbocharged applications. Street performance enthusiasts often choose Wiseco for their proven durability in daily driven builds.

JE Pistons specializes in custom copa piston manufacturing, offering precise compression ratio calculations for exact engine combinations. They provide detailed engineering support and can modify standard designs to accommodate unique camshaft profiles. Professional engine builders frequently rely on JE for their attention to dimensional accuracy and material consistency.

CP Pistons focuses on high RPM applications where lightweight construction becomes critical for performance. Their copa pistons use advanced aluminum alloys that reduce reciprocating mass while maintaining strength under extreme conditions. Many Formula drift and road racing teams choose CP for their superior fatigue resistance.

Mahle Motorsports brings OEM manufacturing expertise to the aftermarket, producing copa pistons that meet strict tolerances for professional racing applications. They offer comprehensive technical documentation and engineering support for complex builds. Their pistons feature advanced ring groove treatments that extend component life in high stress environments.

Diamond Racing Pistons manufactures copa pistons specifically for nitrous oxide applications, using proprietary alloys that resist thermal shock. They provide specialized coatings that reduce heat transfer and improve ring sealing under extreme cylinder pressures. Drag racing teams often select Diamond for their proven performance in quarter mile applications.

Price Range Comparisons

| Brand | Street Performance | Racing Application | Professional Level |

|---|---|---|---|

| Wiseco | $180-$280 per set | $320-$450 per set | $500-$750 per set |

| JE Pistons | $220-$350 per set | $400-$580 per set | $650-$900 per set |

| CP Pistons | $200-$320 per set | $380-$520 per set | $600-$800 per set |

| Mahle Motorsports | $250-$380 per set | $450-$650 per set | $700-$1,000 per set |

| Diamond Racing | $190-$300 per set | $350-$500 per set | $550-$850 per set |

Street performance copa pistons typically cost between $180 and $380 per set, depending on the manufacturer and exact features included. These pistons work well for mild to moderate performance upgrades with compression ratios between 9:1 and 11:1. Most street applications can achieve excellent results within this price range.

Racing application pistons range from $320 to $650 per set and include advanced features like ceramic coatings, lightweight construction, and specialized ring packages. These designs handle higher RPMs and boost pressures that exceed street performance capabilities. Professional racers often invest in this category for competitive advantages.

Professional level copa pistons command premium prices from $500 to $1,000 per set due to their exotic materials and precision manufacturing processes. They feature custom compression ratios, specialized coatings, and engineering support from the manufacturer. Top tier racing teams justify these costs through improved performance and reliability.

Warranty and Support Options

Wiseco provides a one year warranty against manufacturing defects and offers technical phone support during business hours. They maintain detailed installation guides and compatibility charts on their website. Racing teams can access extended warranty programs through their professional dealer network.

JE Pistons offers comprehensive warranty coverage that includes manufacturing defects and material failures for 12 months from purchase date. Their technical support team provides engineering assistance for custom applications and compression ratio calculations. They also offer rebuild services for damaged pistons at reduced costs.

CP Pistons backs their copa pistons with a limited warranty that covers defects in materials and workmanship. They provide technical documentation and installation instructions with each piston set. Professional racing teams can access priority support and expedited replacement services.

Mahle Motorsports extends their OEM quality standards to aftermarket warranty coverage, offering protection against premature failure under normal operating conditions. They maintain technical hotlines staffed by experienced engineers who can assist with installation questions. Their warranty program includes coverage for both street and racing applications.

Diamond Racing Pistons provides warranty coverage specifically designed for extreme performance applications, including nitrous oxide and forced induction systems. They offer technical support through phone consultation and detailed application guides. Their warranty terms account for the demanding conditions these pistons encounter in competition environments.

Troubleshooting Common Copa Piston Problems

Even high-quality copa pistons can develop problems that affect engine performance and reliability. We’ll guide you through identifying and resolving the most frequent issues that occur with these specialized components.

Diagnosing Piston Ring Issues

Ring problems represent the most common copa piston failures we encounter in high-performance applications. Worn or damaged rings typically manifest as excessive blow-by gases escaping past the piston rings into the crankcase. You’ll notice increased crankcase pressure that forces oil vapors through the PCV system and valve covers.

Carbon buildup on ring lands indicates stuck or seized rings that can’t expand properly against cylinder walls. This condition reduces compression ratios by 15-25% and creates uneven wear patterns. We recommend using a compression gauge to test each cylinder and compare readings against manufacturer specifications.

Oil consumption increases dramatically when rings lose their sealing ability. Expect consumption rates to jump from normal levels of 1 quart per 3,000 miles to 1 quart per 500 miles with severely worn rings. Blue smoke from the exhaust during acceleration confirms oil burning in the combustion chamber.

Ring gap measurements help determine replacement necessity. Standard copa piston rings maintain gaps between 0.016-0.024 inches when new. Gaps exceeding 0.035 inches indicate excessive wear requiring immediate replacement to prevent further engine damage.

Addressing Cylinder Wall Scoring

Scoring damage appears as vertical scratches or gouges on cylinder walls that compromise piston ring sealing. These marks typically result from contaminated oil, insufficient lubrication, or debris entering the combustion chamber through damaged air filtration systems.

Surface roughness measurements using a profilometer reveal scoring severity. Cylinders with roughness readings exceeding 32 microinches require immediate attention to prevent copa piston damage. Light scoring under 16 microinches can often be addressed through honing procedures.

Contamination sources must be eliminated before addressing scoring issues. We inspect oil samples for metal particles that indicate ongoing wear processes. Fuel dilution, coolant leaks, and air filter failures represent common contamination causes in high-performance applications.

Repair options depend on scoring depth and cylinder condition. Light scoring responds to cylinder honing with proper crosshatch patterns at 45-degree angles. Deep scoring exceeding 0.003 inches requires overboring cylinders and installing oversized copa pistons to restore proper clearances.

Metal particles in oil filters indicate active scoring processes. Filter analysis reveals aluminum, iron, or chrome particles that help identify whether copa pistons, cylinder walls, or rings are experiencing excessive wear rates.

Resolving Compression Loss Problems

Compression loss reduces engine power output and affects fuel efficiency in copa piston applications. We measure compression ratios using specialized gauges that account for copa piston crown geometry and chamber volumes. Readings below 85% of specification indicate important problems requiring investigation.

Valve seat recession causes compression loss by increasing combustion chamber volume. This condition particularly affects engines running unleaded fuel without proper valve seat hardening. We check valve-to-piston clearances to ensure adequate relief depths in copa piston crowns.

Head gasket failures create compression loss between cylinders or into cooling passages. Combustion gas analyzers detect hydrocarbons in coolant that confirm head gasket problems. Copa pistons with damaged crowns can contact cylinder heads if gasket failure allows excessive deck height changes.

Timing chain stretch affects compression ratios by altering valve timing events. Chains stretched beyond 0.5 inches create late intake valve closing that reduces effective compression. We use timing lights and degree wheels to verify camshaft timing accuracy with copa piston installations.

Carbon deposits on copa piston crowns alter compression ratios and create hot spots that promote detonation. Deposits exceeding 0.020 inches thickness require removal through walnut shell blasting or chemical cleaning methods. Regular carbon cleaning maintains optimal compression ratios in high-performance applications.

Performance Benefits of Upgrading Copa Pistons

Upgrading to quality copa pistons transforms engine performance through optimized combustion efficiency and power delivery. We’ll explore the measurable advantages these specialized components provide across different performance metrics.

Improved Engine Efficiency

Copa pistons optimize combustion chamber geometry to achieve superior thermal efficiency compared to standard designs. The cup-shaped crown creates ideal air-fuel mixture turbulence that promotes complete fuel burning, reducing wasted energy through unburned hydrocarbons.

Compression ratio optimization directly impacts engine efficiency through enhanced combustion pressure. Copa pistons typically increase static compression ratios by 0.5 to 1.5 points above stock configurations, translating to 8-12% efficiency gains in most applications.

Heat management improves significantly with ceramic-coated copa pistons that reduce heat transfer to engine oil by 15-20%. This thermal control maintains optimal operating temperatures while preventing power-robbing heat soak conditions during extended performance driving.

Reduced friction losses occur through precision-manufactured crown surfaces and optimized ring lands. Modern copa pistons feature DLC coatings that decrease internal friction by 3-7%, allowing more power to reach the drivetrain instead of being lost to mechanical resistance.

Enhanced Horsepower Output

Forged copa pistons unlock substantial power gains through improved combustion control and structural integrity. Street performance applications typically see 12-18 horsepower increases, while racing configurations can deliver 25-40 additional horsepower depending on supporting modifications.

Flame propagation enhancement results from the copa crown’s ability to direct combustion gases more efficiently. This controlled burn pattern increases peak cylinder pressures by 8-15%, directly translating to increased torque output across the RPM range.

Higher RPM capability becomes possible with lightweight forged construction that reduces reciprocating mass. Copa pistons enable safe operation at 500-1,000 RPM beyond stock limits, expanding the usable power band for performance applications.

Valve relief optimization allows aggressive camshaft profiles without piston-to-valve interference. This compatibility enables lift increases of 0.050-0.100 inches over stock specifications, improving airflow and peak power potential.

Better Fuel Economy Results

Copa pistons deliver measurable fuel economy improvements through enhanced combustion efficiency and reduced parasitic losses. Real-industry testing shows 5-12% fuel economy gains in street-driven vehicles equipped with properly tuned copa piston assemblies.

Complete combustion reduces fuel waste through optimized flame travel patterns within the copa crown geometry. This improved burn efficiency allows leaner air-fuel ratios while maintaining power output, directly improving miles per gallon calculations.

Lower operating temperatures achieved through ceramic coatings reduce the engine’s cooling system load. Decreased cooling fan operation and reduced heat rejection to the cooling system improve overall vehicle efficiency by 2-4%.

Reduced knock sensitivity enables advanced timing strategies that optimize fuel consumption. Copa pistons’ superior heat dissipation allows 2-4 degrees of additional timing advance, improving thermal efficiency while maintaining reliability margins.

| Fuel Economy Metric | Stock Pistons | Copa Pistons | Improvement |

|---|---|---|---|

| City MPG | 18-22 | 20-24 | 8-12% |

| Highway MPG | 24-28 | 26-31 | 6-10% |

| Combined MPG | 21-25 | 23-27 | 7-11% |

Cost Considerations for Copa Piston Replacement

Copa piston replacement represents a important investment in your vehicle’s performance. Understanding the financial aspects helps you plan effectively for this crucial engine upgrade.

Parts and Labor Expense Breakdown

Copa piston costs vary dramatically based on your performance requirements and brand selection.

OEM replacement copa pistons typically range from $150 to $300 per cylinder, while aftermarket street performance options cost between $200 to $500 each. Racing-grade copa pistons command premium prices from $400 to $800 per piston, with professional competition models reaching $1,000 or more.

Labor expenses constitute the largest portion of your total investment.

Professional installation requires 15 to 25 hours of skilled technician time, translating to $1,500 to $3,500 in labor costs at standard shop rates. Engine disassembly alone accounts for 40% of the total labor time, while precision fitting and assembly consume the remaining hours.

Additional components increase your overall parts budget significantly.

Piston rings add $30 to $80 per cylinder, gasket sets range from $200 to $500, and connecting rod bearings cost $150 to $300 for a complete set. Machine shop services for cylinder honing or resurfacing can add another $300 to $800 to your project.

Factors Affecting Total Repair Costs

Engine configuration directly impacts your replacement expenses.

V8 engines require eight copa pistons compared to four for inline engines, essentially doubling your parts costs. Turbocharged applications demand specialized pistons with enhanced heat resistance, increasing individual piston prices by 30% to 50%.

Machine shop requirements can substantially increase project costs.

Cylinder bore conditions determine whether standard honing ($150 to $300) or complete reboring ($500 to $1,200) becomes necessary. Deck height corrections add $200 to $500 per cylinder head, while connecting rod reconditioning costs $75 to $150 per rod.

Geographic location influences both parts availability and labor rates.

Metropolitan areas typically charge 20% to 40% higher labor rates than rural shops, while specialized performance shops command premium pricing for their expertise. Parts shipping costs increase for remote locations without local performance parts distributors.

Money-Saving Tips for Budget Conscious Drivers

Timing your replacement strategically reduces overall project costs.

Combining copa piston installation with scheduled engine rebuilds eliminates duplicate labor charges for disassembly and reassembly. Planning during off-season periods often yields better shop scheduling and potentially lower rates.

Sourcing strategies significantly impact your parts expenses.

Purchasing complete piston sets directly from manufacturers eliminates distributor markups, saving 15% to 25% on total parts costs. Group purchases with other enthusiasts or racing teams often qualify for volume discounts from specialty suppliers.

DIY preparation work reduces professional labor requirements.

Performing engine removal and initial disassembly yourself can save $500 to $1,000 in shop time. Cleaning components and organizing hardware before professional assembly reduces billable hours while ensuring nothing gets lost during the process.

Alternative sourcing options provide budget friendly answers.

Remanufactured copa pistons offer 70% of new performance at 60% of the cost, making them ideal for street applications. Used racing pistons from reputable sources provide excellent value when properly inspected by qualified technicians.

Conclusion

Copa pistons represent a crucial investment for anyone seeking enhanced engine performance and reliability. Whether you’re building a street machine or preparing for the track these specialized components deliver measurable improvements in power output and fuel efficiency.

We’ve explored how proper selection installation and maintenance can maximize your return on investment. From understanding material differences to recognizing failure symptoms the knowledge you’ve gained empowers you to make informed decisions about your engine’s future.

The performance benefits speak for themselves through improved compression ratios better thermal management and increased horsepower. While the upfront costs may seem important the long-term gains in reliability and performance make copa pistons a worthwhile upgrade for serious automotive enthusiasts.

Remember that success with copa pistons depends on matching them to your exact application and maintaining them properly. With the right approach you’ll enjoy years of enhanced driving performance and engine efficiency.

Frequently Asked Questions

What are copa pistons and how do they differ from standard pistons?

Copa pistons are specialized engine components featuring a cup-shaped crown design that optimizes combustion chamber geometry. Unlike standard flat-top pistons, copa pistons have a concave surface that reduces combustion chamber volume, improves compression ratios, and enhances air-fuel mixture control. They’re primarily used in high-performance and racing applications where power output and efficiency are critical.

What materials are copa pistons made from?

Copa pistons are typically manufactured from aluminum alloys, with 2618 and 4032 being the most common types. Forged aluminum provides the strongest option for extreme performance applications. Many copa pistons also feature ceramic coatings to reduce heat transfer and friction, which extends component life and improves overall engine performance.

What are the signs that copa pistons need replacement?

Common symptoms include engine knocking, unusual noises indicating cracks or excessive clearances, loss of power and poor acceleration due to compromised compression ratios, and excessive oil consumption leading to blue smoke from the exhaust. Carbon buildup on spark plugs is another warning sign that shouldn’t be ignored.

How do I choose the right copa piston for my engine?

Consider your engine’s displacement, connecting rod specifications, valve relief requirements, and deck height measurements. Decide between OEM pistons for original specifications or aftermarket options for enhanced performance. Key factors include compression ratios, thermal expansion coefficients, weight specifications, and your specific performance goals.

Should I install copa pistons myself or hire a professional?

While DIY installation is possible with proper tools and expertise, professional installation is recommended due to the precision required. Professionals have access to specialized equipment like torque wrenches, piston ring compressors, and precision measuring instruments. Common DIY mistakes include incorrect ring orientation and improper torque procedures.

How do I maintain copa pistons for optimal performance?

Change engine oil every 3,000 to 5,000 miles using high-quality synthetic oil. Monitor engine temperatures with high-capacity cooling systems and use premium fuel with high octane ratings. Regular fuel system cleaning prevents carbon buildup, and oil analysis helps monitor wear patterns for early problem detection.

Which brands make the best copa pistons?

Top manufacturers include Wiseco Performance Products, JE Pistons, CP Pistons, Mahle Motorsports, and Diamond Racing Pistons. Each brand offers unique advantages for different applications, with price ranges varying from street performance ($200-$500) to professional racing levels (over $1,000 per piston).

What performance benefits do copa pistons provide?

Copa pistons improve combustion efficiency through enhanced thermal management, increased compression ratios, and reduced friction losses. They deliver measurable gains in horsepower and fuel economy, with improvements in miles per gallon across city, highway, and combined driving conditions, making them valuable for both street and racing applications.

How much does copa piston replacement cost?

Parts costs range from $150-$300 per cylinder for OEM pistons, $200-$500 for aftermarket options, and over $1,000 for racing-grade pistons. Professional installation labor typically costs $1,500-$3,500, depending on engine complexity and geographic location. Total costs vary based on engine configuration and specific requirements.

How do I troubleshoot common copa piston problems?

Diagnose piston ring issues by checking for excessive blow-by gases and oil consumption. Look for cylinder wall scoring and address contamination sources. Compression loss problems may indicate valve seat recession, head gasket failures, or carbon deposits on piston crowns. Regular monitoring and early intervention prevent costly engine damage.